Precision resistance welding spot welding machine

A kind of precision resistance, welding machine technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

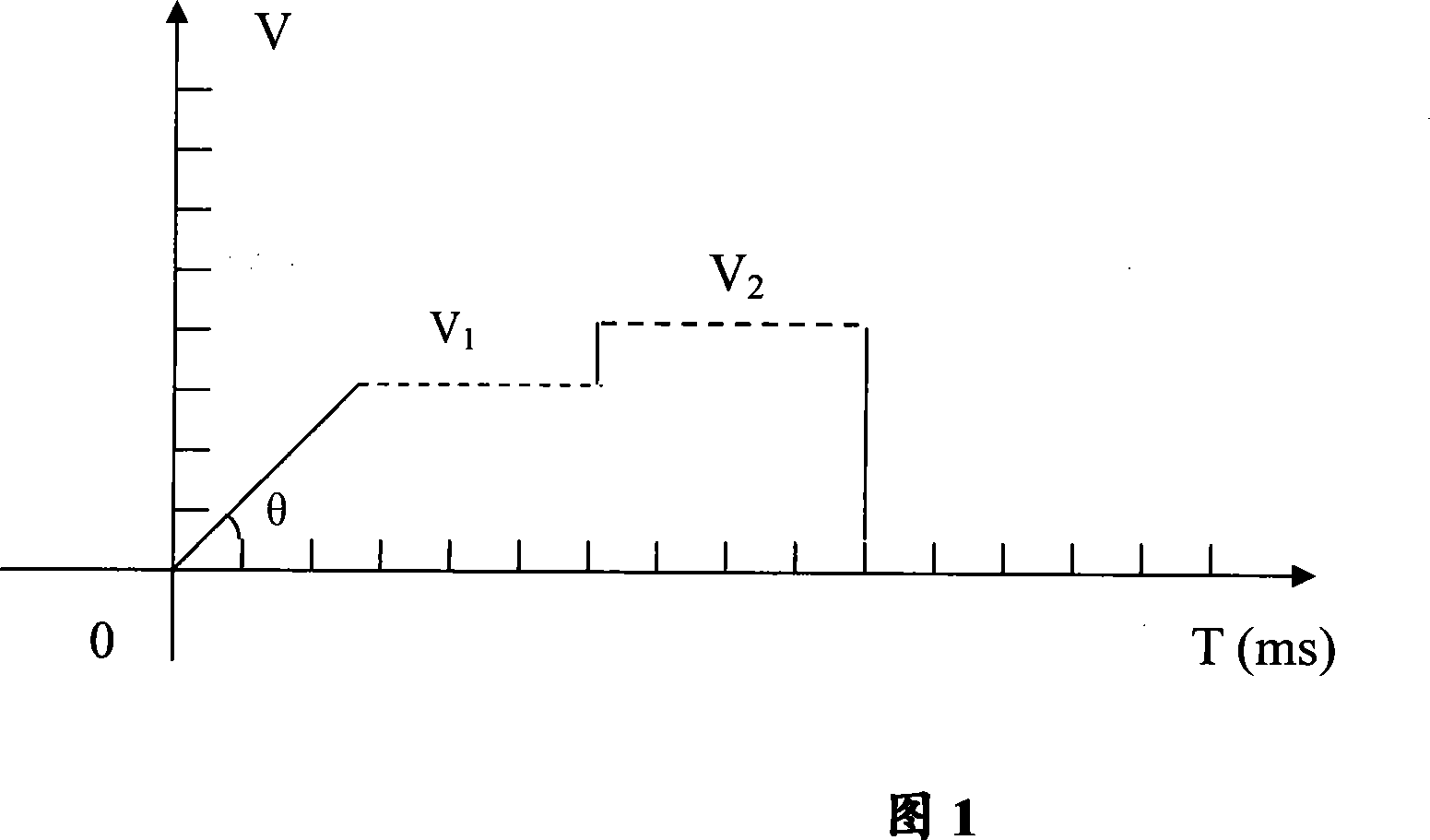

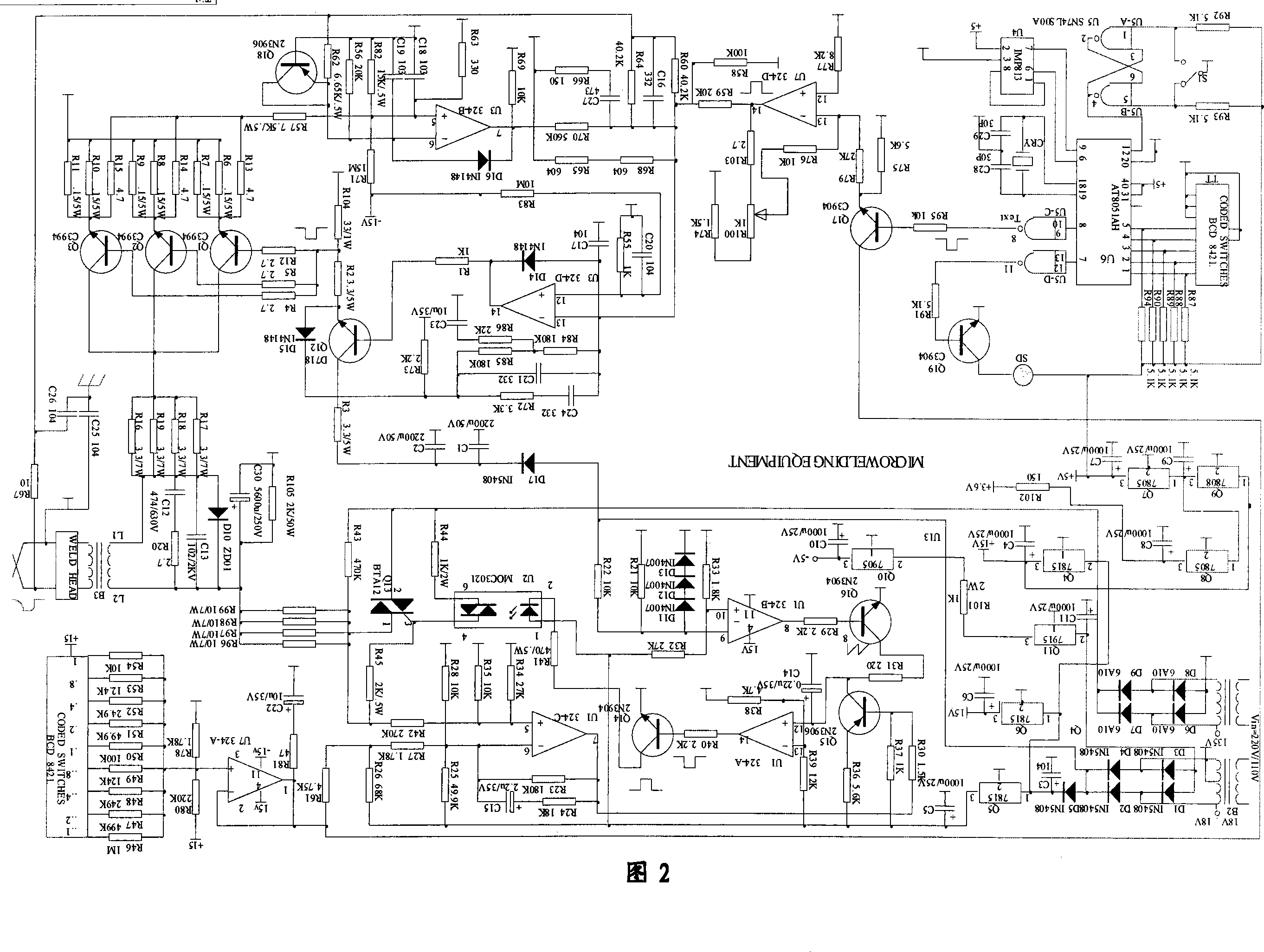

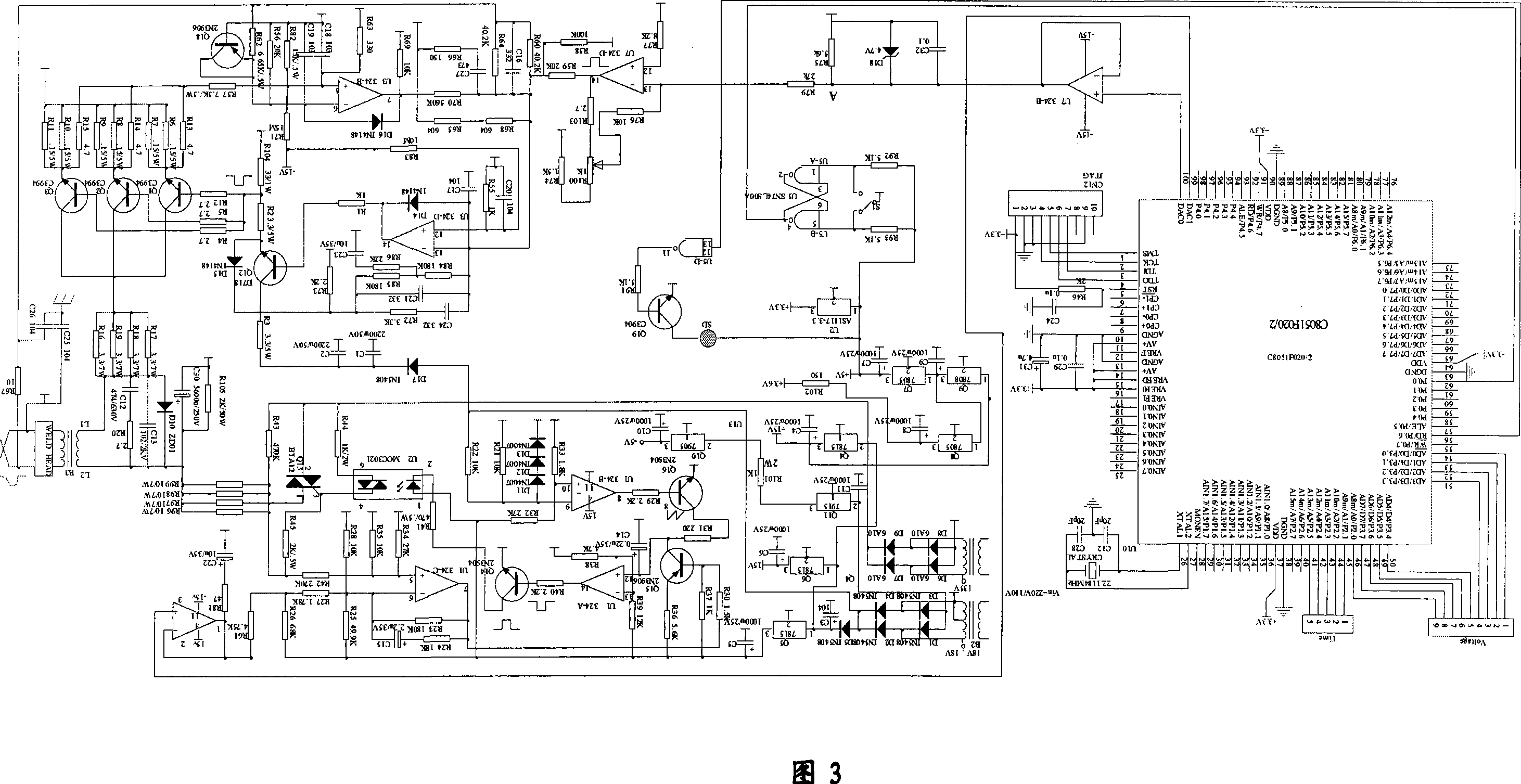

[0025] The specific implementation of the precision resistance welding spot welding machine of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] To directly weld the enameled wire, it is generally necessary to use a prestressed spot welding electrode (patent No. 93245377.5), a spot welding tip (patent No. 01114808.X) or a resistance welding tip and its preparation method (patent No. 2005121259.2). head. Judging from the structures of these welding heads, the tips of the two electrodes that constitute the welding head are stress contact ohmic contact or conjoined. After a lot of experiments, research and analysis, the present invention finds that the principle of direct welding enameled wire can be summarized as follows: when welding, conduction current, because there is an insulating layer on the enameled wire, the current all flows through the tips of the two electrodes of the welding head, so that the tip of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com