QS-4 elastic body processing technique for sensor

A processing technology and elastomer technology, which is applied in the field of QS-4 elastomer processing technology for sensors, can solve the problems of poor sensor stability, affecting product quality, poor surface finish of the bottom plane of the elastomer and poor aperture finish, etc., to achieve high practicability, The effect of improving product quality and solving the concave problem of square hole bottom plane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

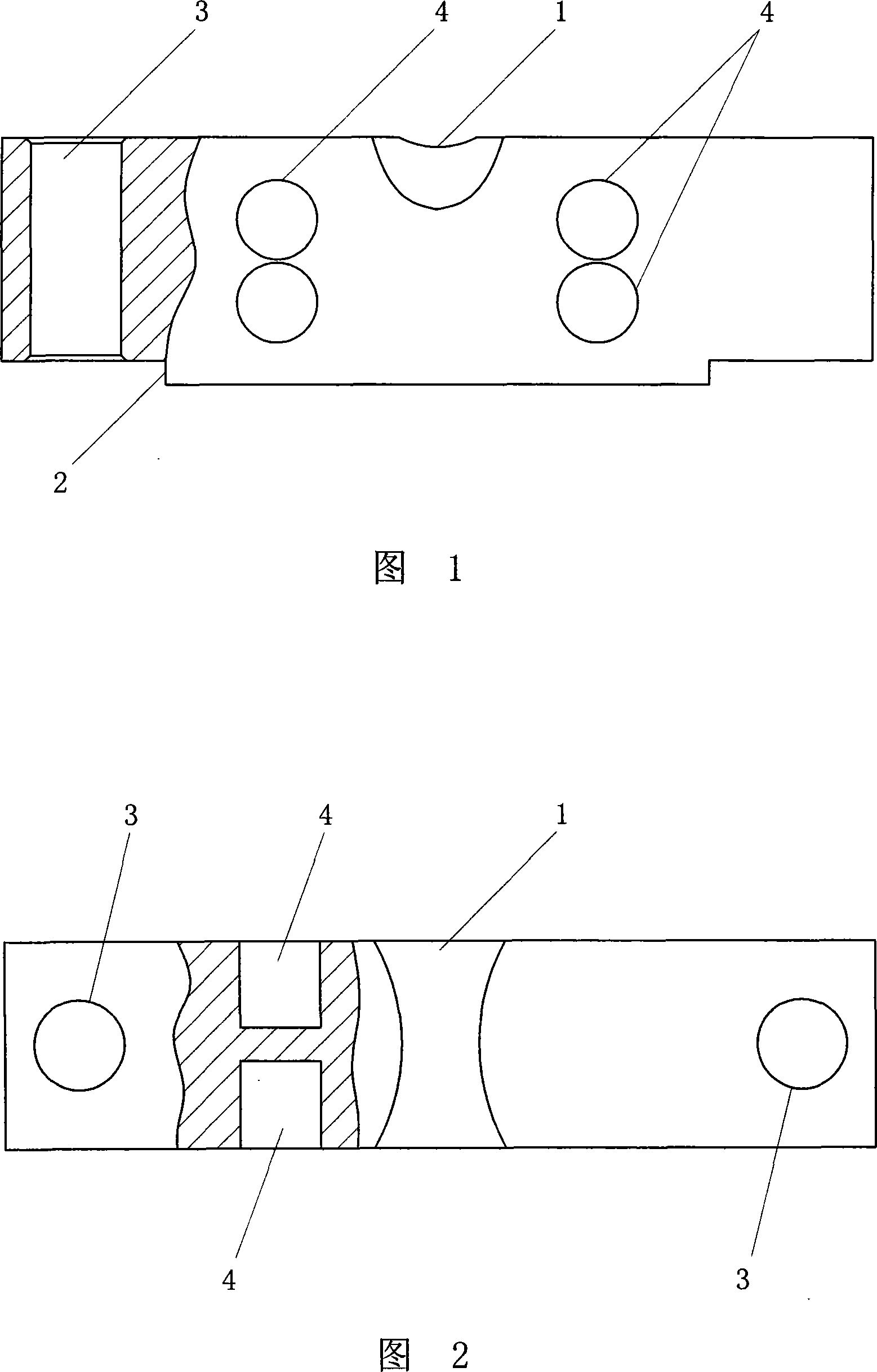

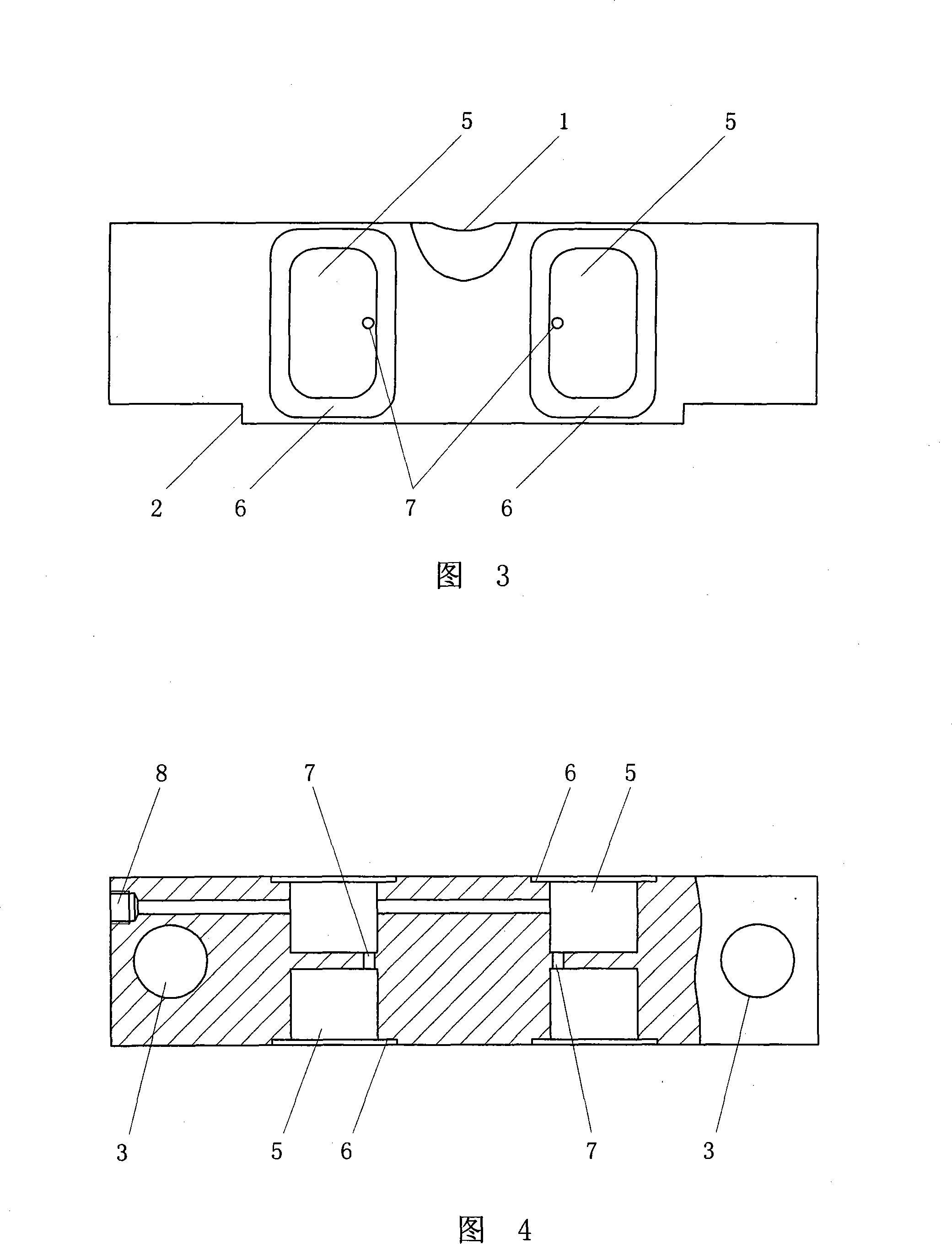

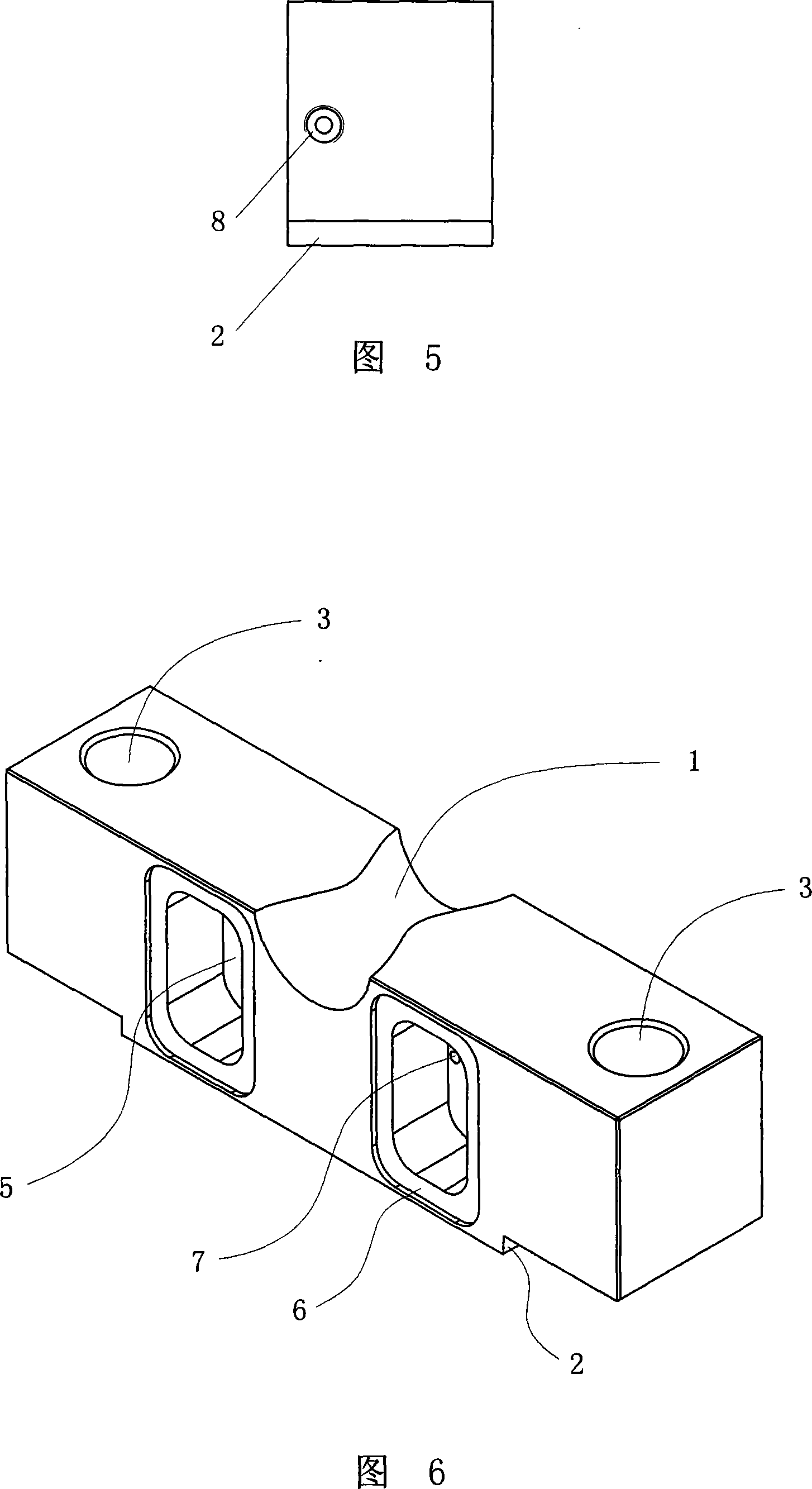

[0036] See Figure 1 to Figure 6, a QS-4 elastomer processing technology for sensors, the blank is made of 65mm*78mm section steel, and the saw length is 265mm; the following steps are adopted:

[0037] a) Milling and grinding the front, back, upper and lower sides of the blank. When grinding the third side, square tooling should be used to ensure that the error of the square on the four sides is within 0.02mm; mill the left and right end faces to control the angle between the end face and the long face Within 0.05mm;

[0038] b) Remove the burr on the outer edge, and it is required not to affect the processing of the subsequent process;

[0039] c) Rough and fine milling of arc 1 in the middle section. When milling, use a dividing head and clamp it with QS-4 special tooling. First, rough mill arc 1 in the middle section, leaving a margin of 0.3 mm and then do a fine milling to ensure the circle in the middle section Arc 1 has a finish of 3.2;

[0040] d) Step 2 on the millin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com