Machining method of waveguide installation hole in satellite antenna frame

A processing method and mounting hole technology, which is applied in the field of processing satellite antenna frame waveguide mounting holes, can solve problems such as quality and reliability cannot be guaranteed, and achieve the effects of improving processing efficiency, good application effects, and avoiding tool setting errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] Such as figure 1 As shown, the present invention provides a method for processing mounting holes of antenna frame waveguide for satellites, comprising:

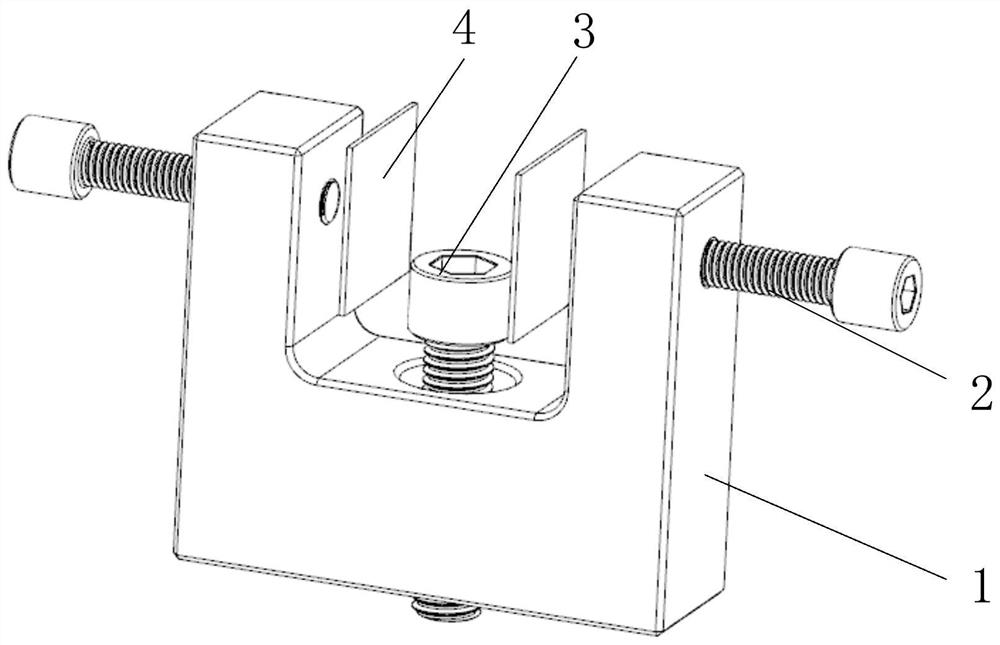

[0031] When milling, use the supporting clamping device and adopt the clamping method of "replacing pressure with support" to clamp the surface to ensure the flatness of milling;

[0032] Carry out a trial cutting test on the forming tool to determine the cutting parameters and the feed rate in the depth direction;

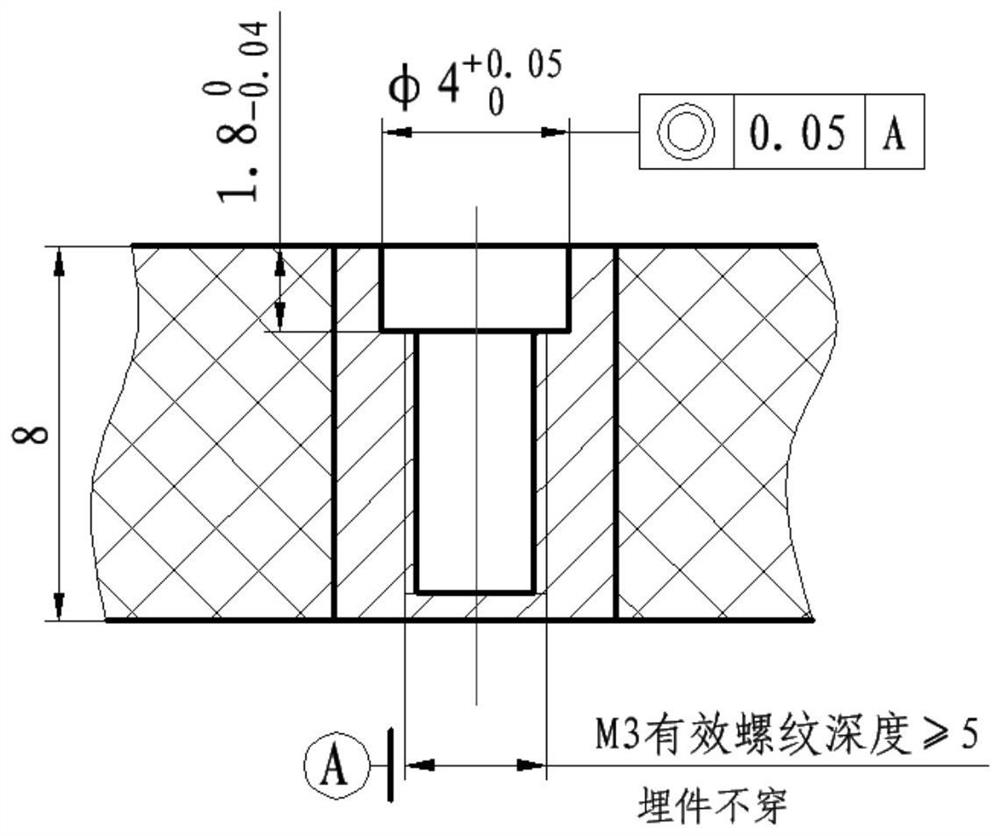

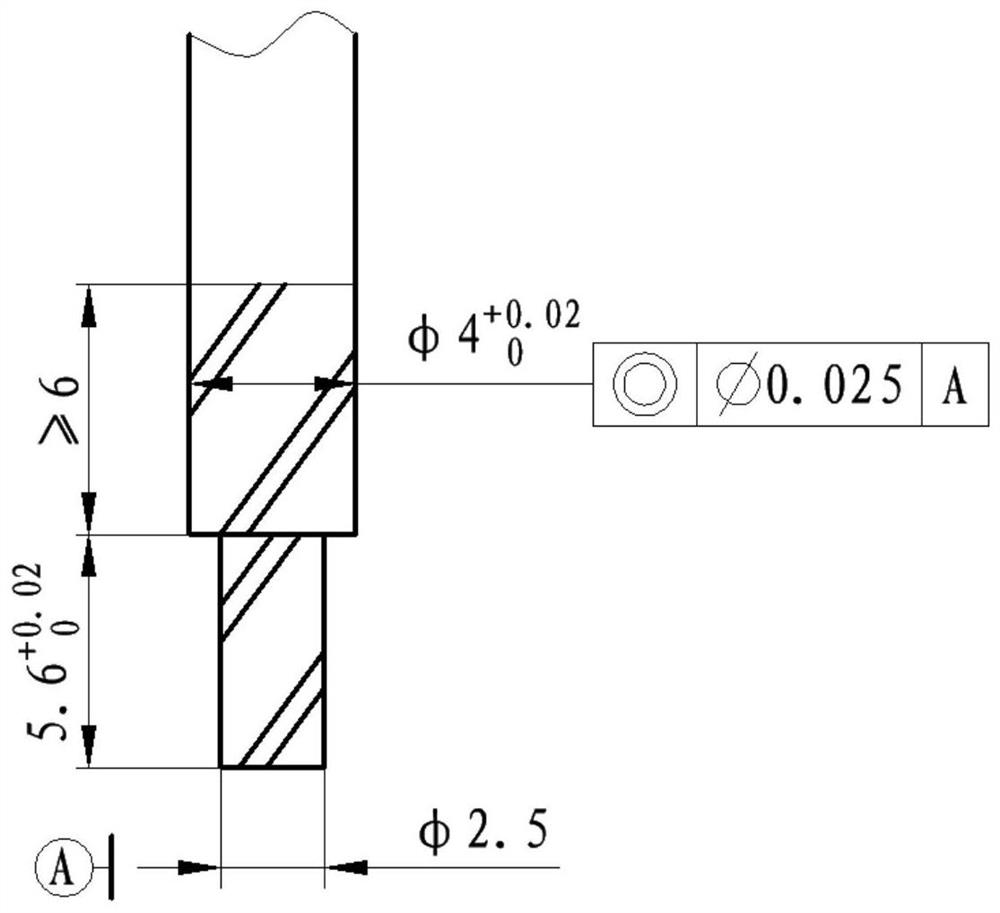

[0033] The forming tool is used to process the waveguide installation hole. When the waveguide hole on the product is finished, the tool is no longer set separately, but is compensated according to the height difference between the surface of the test piece a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com