Destressing system and method for end face sealing static ring of liquid rocket engine

A liquid rocket and end-face sealing technology, applied in the field of stress relief system, can solve the problem of not effectively reducing the residual stress of the end-face sealing static ring, and achieve the effect of reducing the probability of out-of-tolerance repairs, reducing the labor intensity of personnel, and realizing real-time monitoring.

Active Publication Date: 2022-02-08

XIAN AEROSPACE PROPULSION INST

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

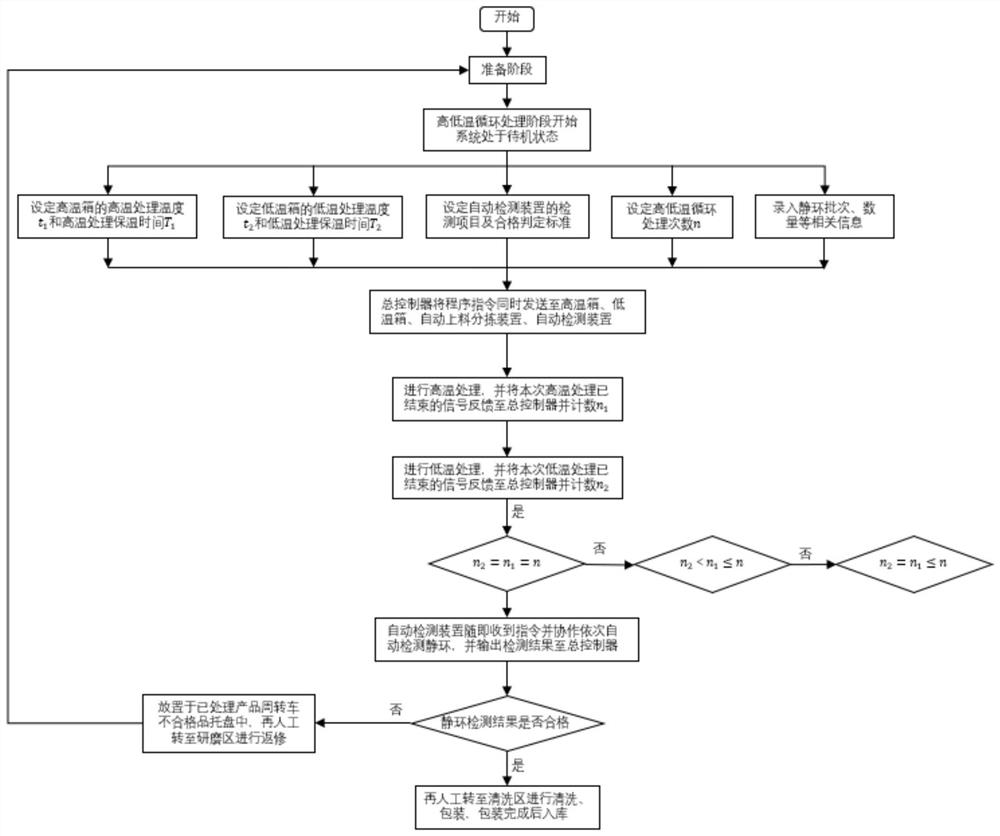

[0015] The purpose of the present invention is to solve the problem that the stress relief method of the existing liquid rocket engine end face seal static ring cannot effectively reduce the end face seal static ring through the optimization of cutting tools and cutting parameters, the optimization of clamping position and clamping tooling, and the optimization of press-fit equipment and press-fit parameters. Insufficient ring residual stress, thereby providing a liquid rocket engine end face seal static ring stress relief system and method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and exemplary embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

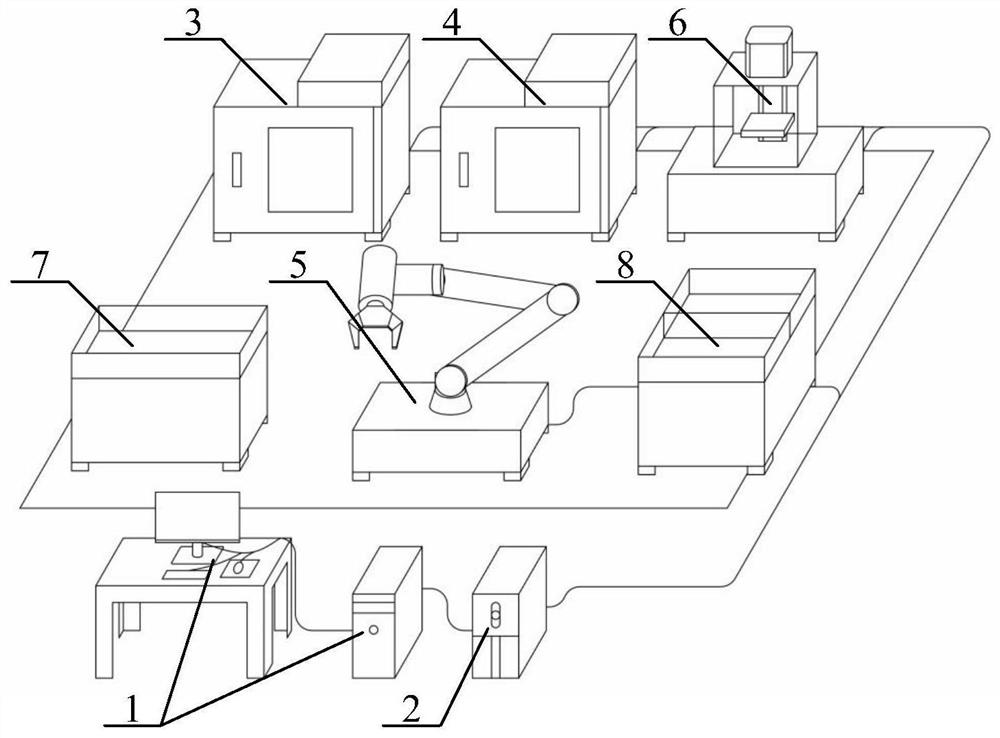

The invention relates to an embedded sealing ring, in particular to a destressing system and method for an end face sealing static ring of a liquid rocket engine. The system and the method are used for overcoming the defect that according to an existing destressing method for the end face sealing static ring of the liquid rocket engine, the residual stress of the end face sealing static ring cannot be effectively reduced through optimization of a cutting tool and cutting parameters, optimization of a clamping position and a clamping tool and optimization of press-fitting equipment and press-fitting parameters. The destressing system for the end face sealing static ring of the liquid rocket engine comprises an upper computer, a master controller, a high-temperature box, a low-temperature box, an automatic feeding and sorting device, an automatic detection device, a to-be-treated product turnover vehicle and a treated product turnover vehicle, the automation degree of the system is improved, the labor intensity of personnel is reduced, and the real-time monitoring of the destressing process is realized. Meanwhile, the invention further provides the destressing method suitable for the end face sealing static ring of the liquid rocket engine.

Description

technical field [0001] The invention relates to a mosaic sealing ring, in particular to a stress relief system and method for a liquid rocket engine end face sealing static ring. Background technique [0002] At present, the static ring of the liquid rocket engine end face seal mostly adopts a mosaic seal ring structure, which usually uses graphite material as the non-metallic seal ring piece, and at the same time uses metal materials such as S-07 and 4J31 as the metal ring seat. The force generated by radial deformation during interference fit makes the non-metallic sealing ring and the metal ring seat tightly combined. The inlaid sealing ring structure can not only ensure good centering, but also can transmit torque reliably and effectively, meeting the high-reliability requirements of sealing under high-frequency shock and vibration. However, due to the particularity of the structure of the mosaic seal ring, internal residual stress must be generated by machining during ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C21D9/40C21D11/00C21D1/78C01B32/21B07C5/34

CPCC21D9/40C21D9/0018C21D11/00C21D1/785C01B32/21B07C5/34Y02P90/02

Inventor 张玻溶孙浩刘伟常涛吴朝辉姜文权杨祎

Owner XIAN AEROSPACE PROPULSION INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com