Exploding bottom-expanding pile-forming method for immersed tube prefabrication steel concrete bottom-expanding pile

A technology of expanding bottom piles and forming piles, which is applied to sheet pile walls, buildings, and foundation structure engineering, etc., and can solve problems such as potential safety hazards for construction personnel, adverse effects on pile bearing capacity, and discounting of single pile bearing capacity, and achieves a simple process method Advanced, ensuring the quality of pile foundation engineering, and improving the effect of single pile bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

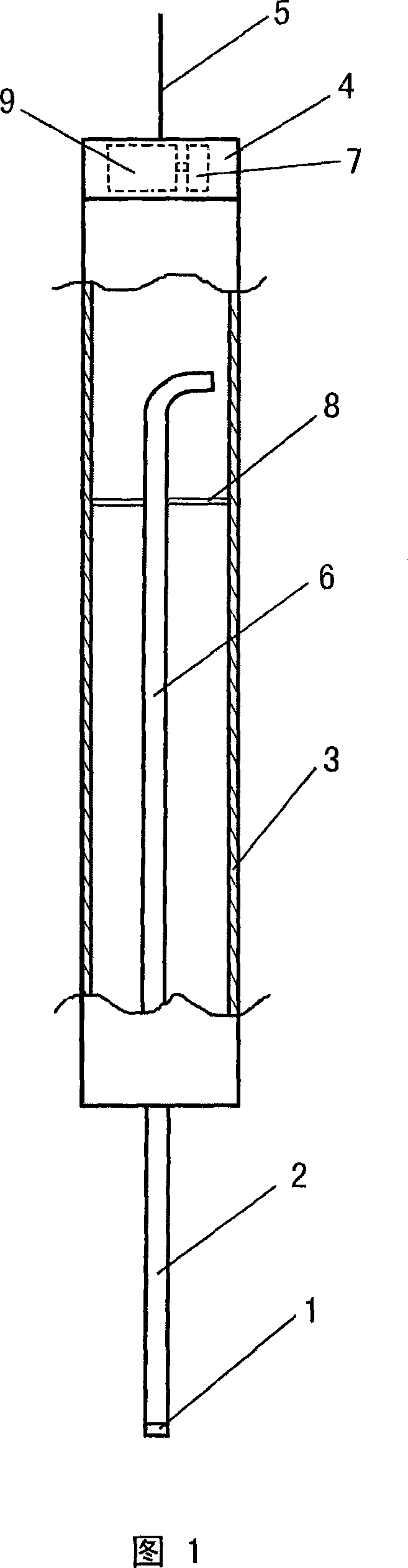

[0026] Embodiment one: the method of blasting and expanding the bottom of the immersed tube prefabricated steel concrete expanded bottom pile, and forming a pile, a, the first section of the immersed tube with the metal pile head is pressed into the soil body, and the second section of the immersed tube and the first section of the immersed tube are pressed into the soil body. The upper end of the tube is threaded, and then the immersed tube is pressed to the hard soil layer at the design level; b. Take out the metal pile head, and put emulsified oil or ammonium antimony explosive from the immersed tube mouth, every 0.5m 3 The dosage is 1-5 kg. After detonating the explosive, seal the mouth of the immersed tube. After the explosion of the explosive is completed, open the article that seals the mouth of the immersed tube; c. Use the air suction soil equipment to take soil, when there is only a small amount of loose soil left in the base , in order to prevent the residual granula...

Embodiment 2

[0027] Embodiment 2: A method of blasting and expanding the bottom of an immersed tube prefabricated steel concrete expanded bottom pile, and forming a pile, a. The integral immersed tube with a metal pile head is passed through the soft soil and laminated to the hard soil layer at the design level; b. Take out the metal pile head, put emulsified oil or ammonium antimony explosive from the mouth of the immersed tube, every 0.5m 3 The dosage is 1-5 kg. After detonating the explosive, seal the mouth of the immersed tube. After the explosion of the explosive is completed, open the article that seals the mouth of the immersed tube; c. Use air suction soil equipment to carry out secondary soil extraction until the soil is cleaned ; d. Use a camera with a light source to check whether the quality meets the design requirements in the cavity of the base, and record and file the image, and correct any problems found in time; e. Put the radial steel bars into the cavity of the base and n...

Embodiment 3

[0028] Embodiment three: the blasting expansion bottom of immersed tube prefabricated steel concrete expanded bottom pile, method of forming a pile, a, the first joint immersed tube with metal pile head is pressed into the soil body, the second joint immersed tube and the first joint sinking tube are pressed into the soil body The upper end of the tube is threaded, and then the immersed tube is pressed to the hard soil layer at the design level; b. Take out the metal pile head, and put emulsified oil or ammonium antimony explosive from the immersed tube mouth, every 0.5m 3 The dosage is 1-5 kg. After detonating the explosive, seal the mouth of the immersed tube. After the explosion of the explosive is completed, open the article that seals the mouth of the immersed tube; c. Take soil with air suction equipment until the soil is clean; d. The radial steel bars are put into the cavity of the base and nailed into the hard soil. The quantitative concrete made on the ground is poure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com