Parallel flow heat converter dedicated for air conditioner

An exchanger and flow heat technology, applied in the field of parallel flow heat exchangers, can solve problems such as limited space, influence on popularization and application, and failure to achieve heat exchange, etc., to eliminate all shortcomings, reduce production costs, and have large heat exchange capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

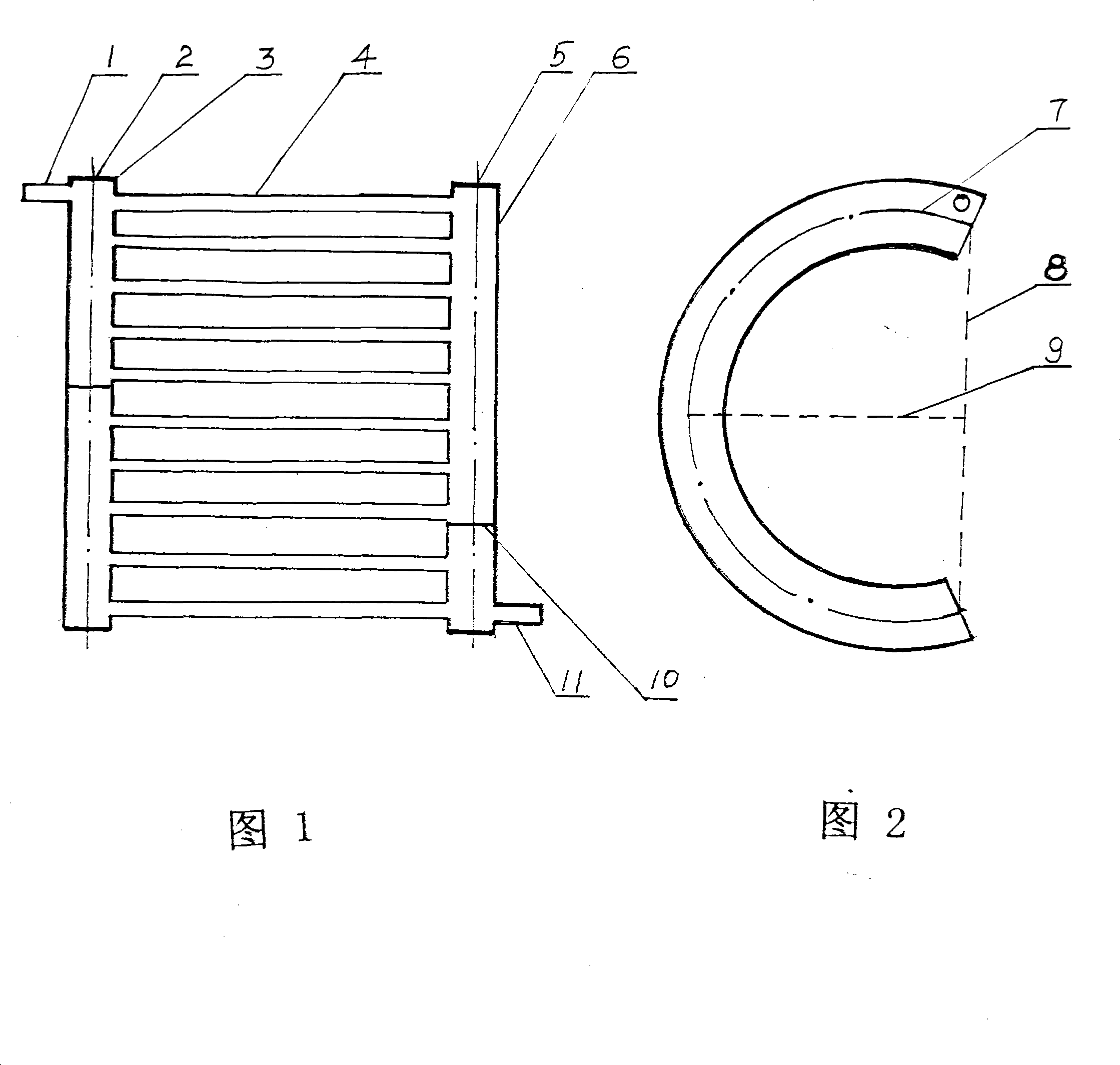

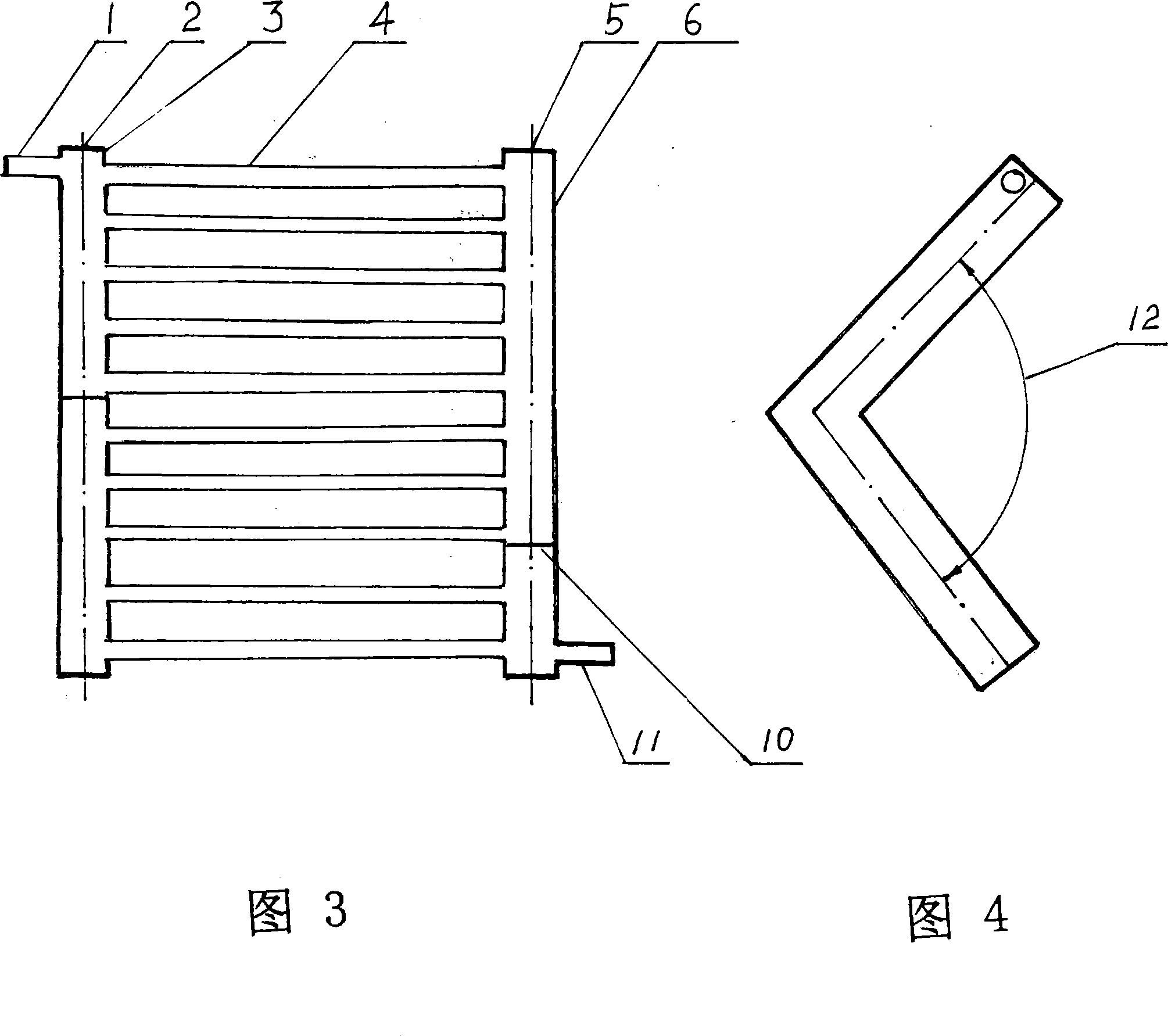

[0021]In the figure, 1 is the refrigerant inlet pipe, 2 is the centerline of the arc-shaped collector, 3 is the arc-shaped collector, 4 is the heat exchange flat tube, and 5 is the centerline of the arc-shaped collector. , 6 is the arc type collector, 7 is the connecting line of the center point of the side projection of the arc type collector, 8 is the chord line, 9 is the arc height, 10 is the spacer, 11 is the refrigerant outlet pipe, 12 is angle.

[0022] This embodiment is an embodiment of the application of the arc type parallel flow heat exchanger of the present invention as an air conditioner condenser: see Fig. 1 and Fig. 2 . Figure 2 clearly shows the structure of the arc collector. 3 and 6 in the figure are a pair of arc-shaped collectors, 2 in the figure is the centerline of the orthographic projection of the arc-shaped collector 3, and 5 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com