LED bracket processing method, LED bracket unit and bracket for LED bare core test

A technology of LED bracket and bracket unit, which is applied in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc. It can solve the problems of not reflecting the real level of LED bare cores, unfavorable LED bare core research, and affecting comprehensive test results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention provides a LED bracket processing method for LED bare core testing.

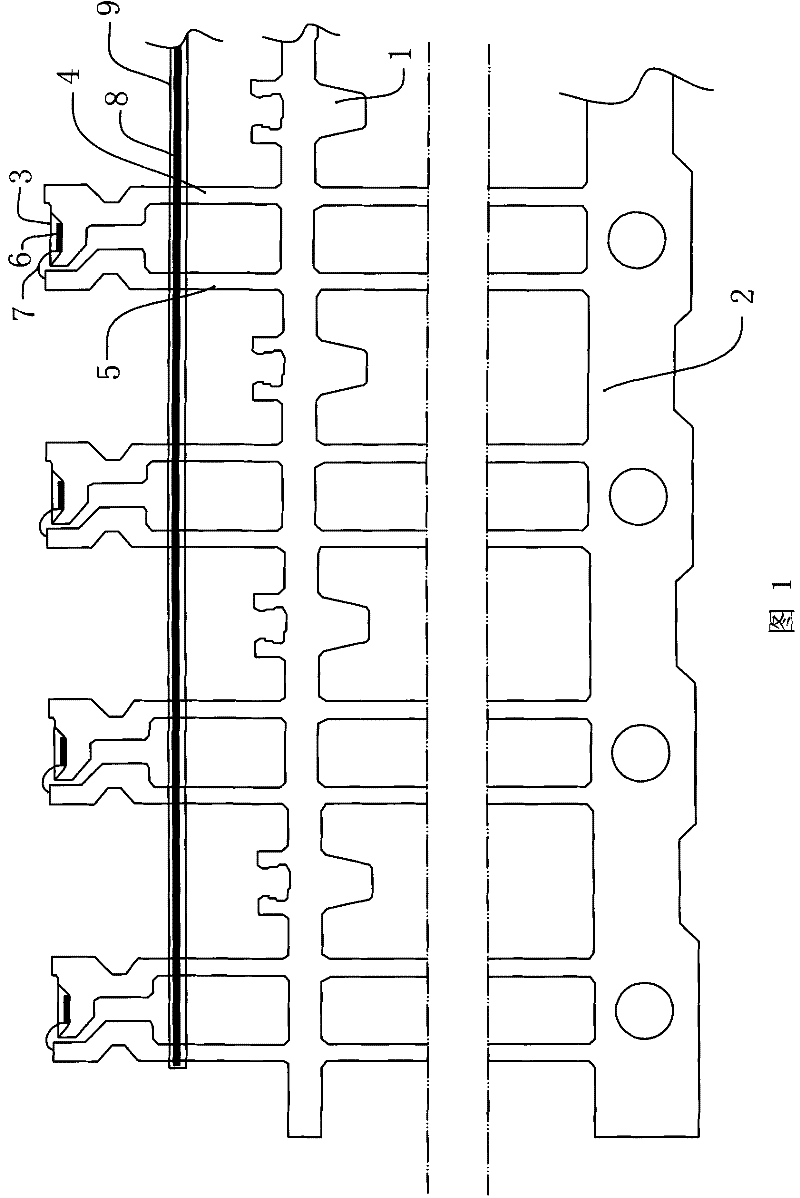

[0022] The product embodiment structure that the present invention relates to is as follows, see figure 1 shown. Generally, an LED bracket is provided with 20 bracket units (4 are shown in the figure, and the others are omitted) connected together, and the bracket units are connected together by the upper rib 1 of the bracket and the lower rib 2 of the bracket.

[0023] A single support unit is mainly composed of a bowl cup 3 , a first electrode pin 4 and a second electrode pin 5 for supporting the bowl cup 3 . An LED chip (i.e. bare core) 6 is placed in the bowl cup 3, and the LED chip 6 is sealed in the bowl cup 3 by epoxy resin. The wire 7 connects the second electrode pin 5 and the LED chip 6 . The upper rib 1 of the bracket connects multiple bracket units, and connects the first electrode pin 4 and the second electrode pin 5 .

[0024] A core wire 8 is wound between the first e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com