Plasma auxiliary high-energy planetary ball mill device

A planetary ball milling and plasma technology, applied in grain processing and other directions, can solve problems such as difficult to improve and complex structure, and achieve the effects of accelerated ball milling, uniform energy reception, and fine powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

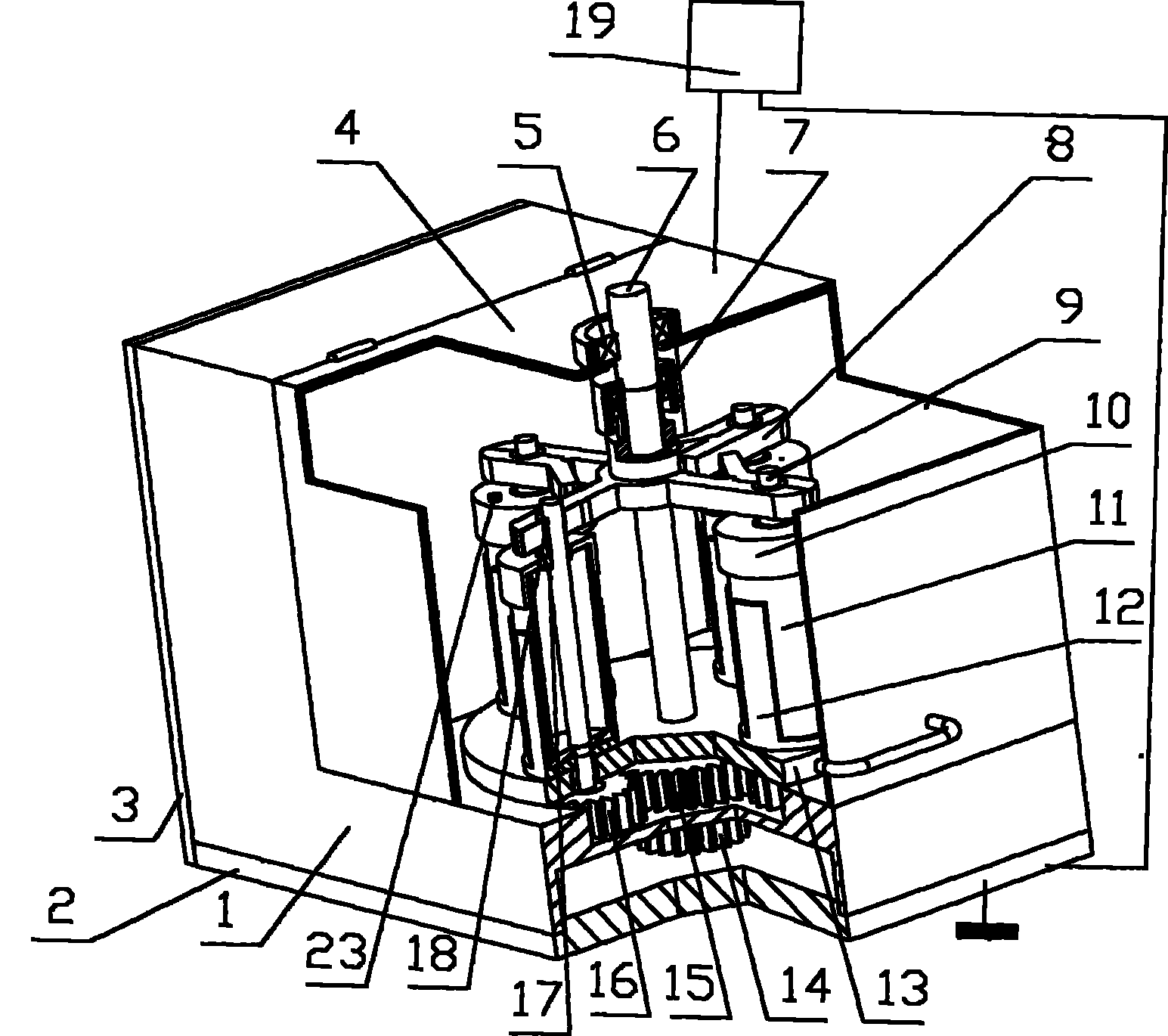

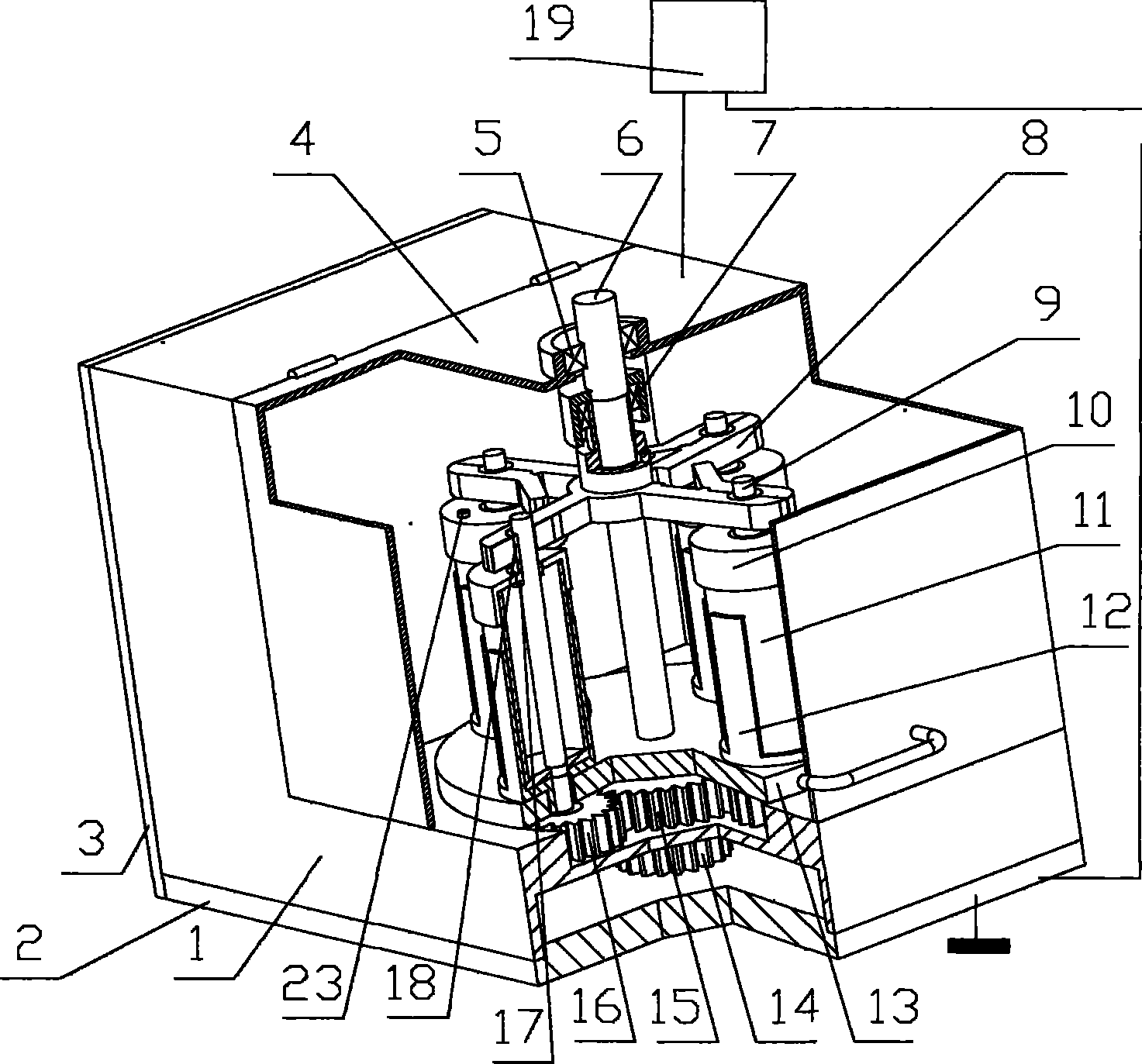

[0024] As shown in Fig. 1 and Fig. 2, the plasma-assisted high-energy planetary ball mill device consists of a chassis 1, a bottom cover 2, a side cover 3, an upper cover 4, an electrode connecting shaft upper bearing 5, an electrode connecting shaft 6, and an electrode connecting shaft when assembled vertically. Lower bearing 7, electrode clamping frame 8, electrode shaft 9, tank cover 10, ball mill tank body 11, tank body positioning seat 12, planetary disc 13, planetary disc drive wheel 14, sun gear 15, planetary gear 16, electrode sealing ring 17. The electrode bearing 18, the power supply 19, the intermediate wheel 20, the motor shaft gear 21, and the driving motor 22 are composed. Their connections are as follows:

[0025] The first part: the electrode shaft 9 is fixedly equipped with an electrode bearing 18, which is fixed on the tank cover 10 with air extraction holes through the electrode sealing ring 17, and the tank cover 10 is closely combined with the ball mill ta...

Embodiment 2

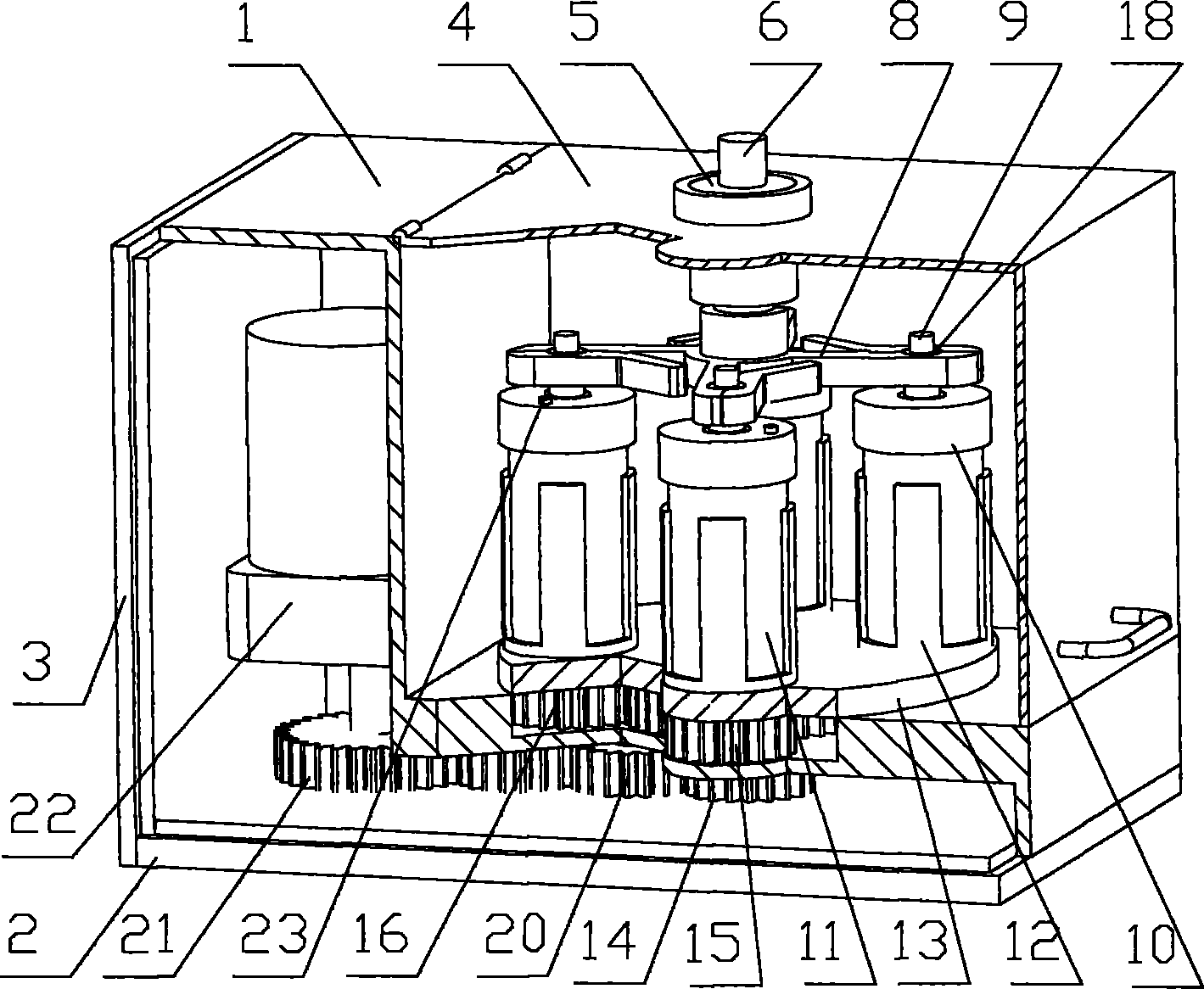

[0032]Fig. 4 is a schematic diagram of the structure of the plasma-assisted high-energy planetary ball mill when the electrodes are assembled horizontally to the shaft. The horizontal assembly of the electrode connecting shaft means that the electrode connecting shaft 6 passes through the side wall of the cabinet 1 through the upper bearing 5 of the electrode connecting shaft, and keeps rotating relative to the cabinet 1, and the lower bearing of the electrode connecting shaft is installed in the bearing hole at the right end of the electrode connecting shaft 6 7. It is flexibly connected with the electrode holding frame 8.

[0033] The connection, assembly relationship and working process of other parts are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com