Liquid spraying device and using method thereof

A liquid spraying and liquid technology, which is applied in the field of liquid spraying equipment and liquid spraying devices, can solve the problems of slow spraying speed, high liquid loss, uneven spraying thickness, etc., and achieve the effect of comprehensive spraying and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

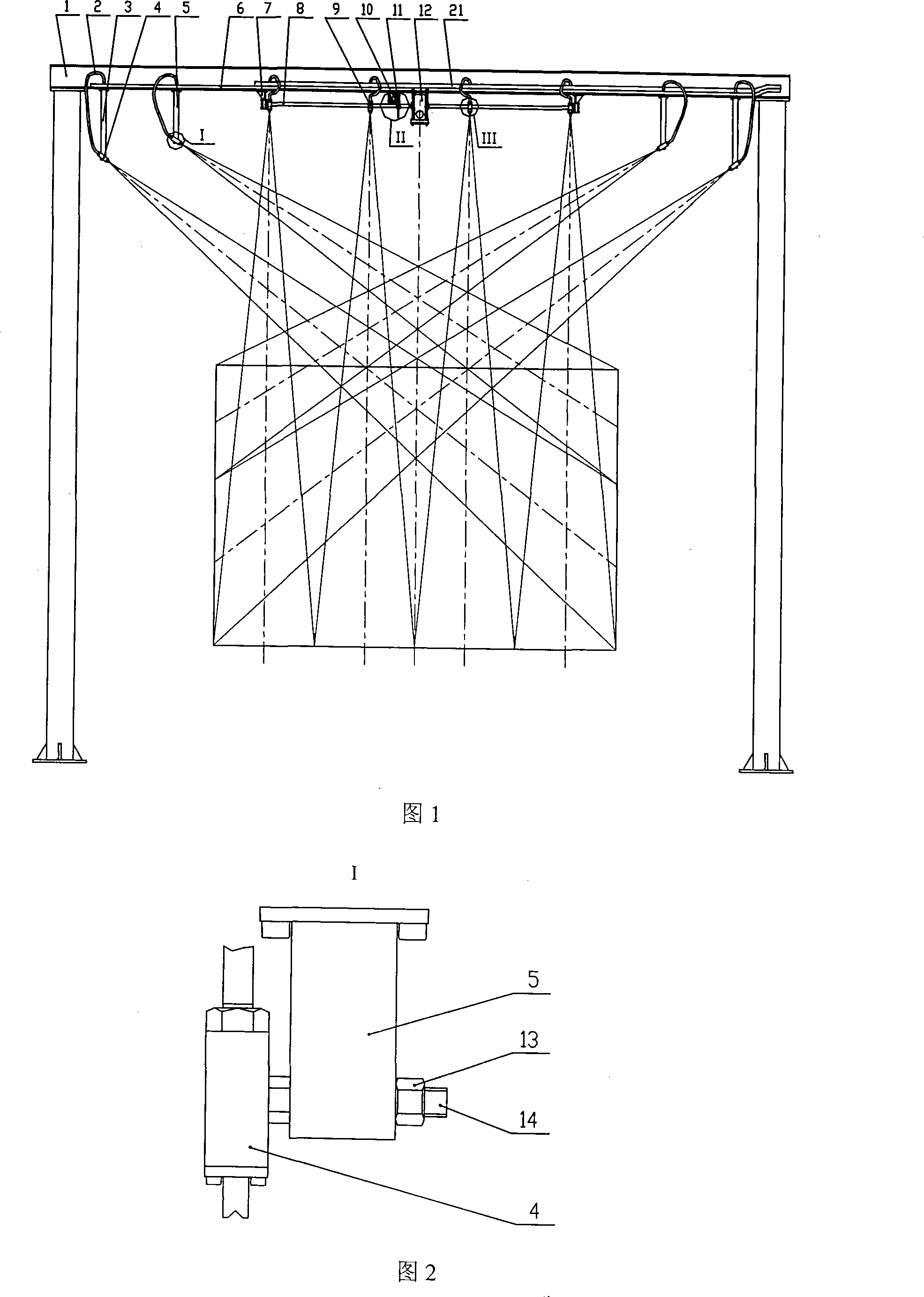

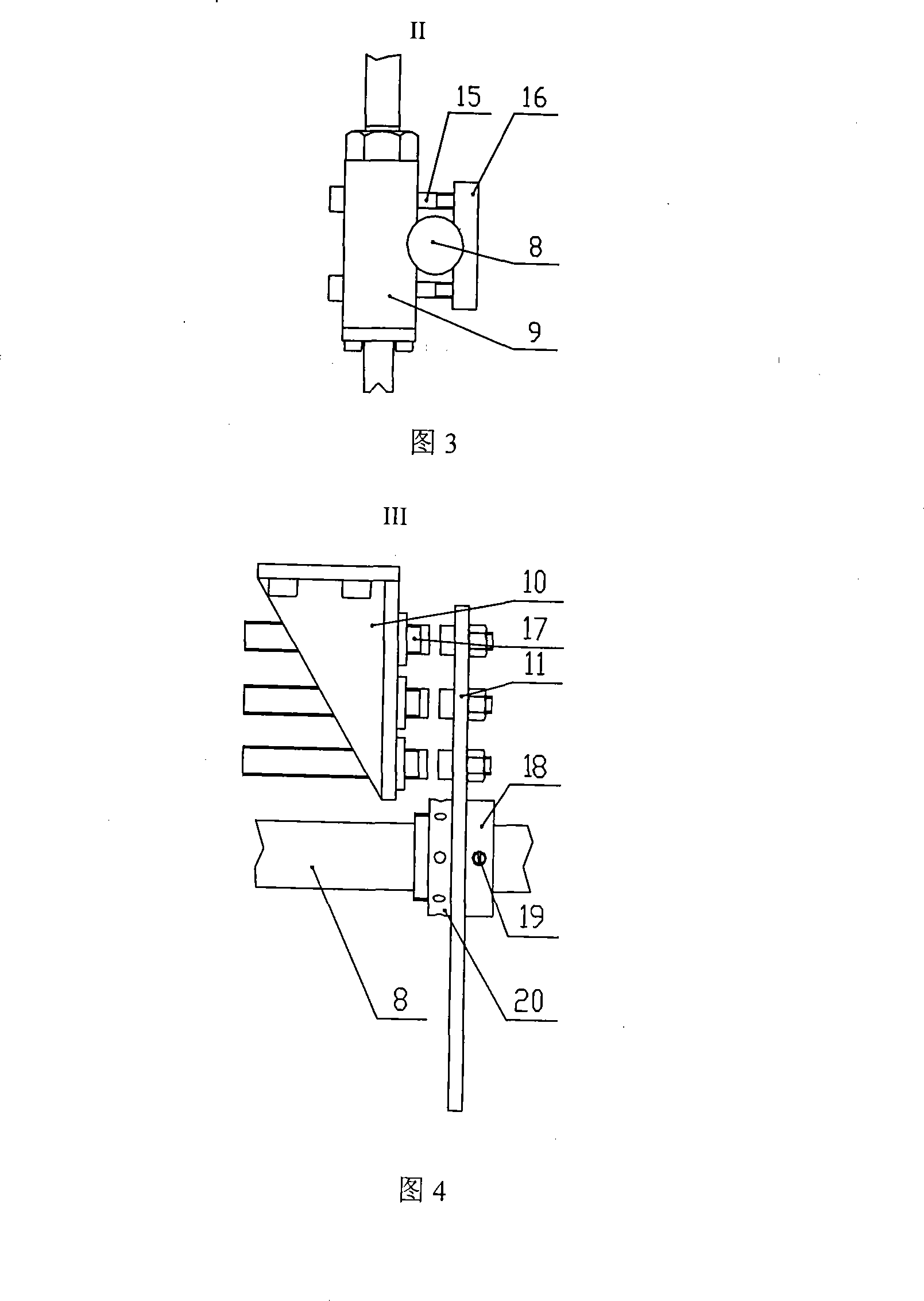

[0023] A liquid spraying device, characterized in that it mainly consists of a gantry 1, an infusion tube 2, a long fixed nozzle support 3, a short fixed nozzle support 5, a fixed nozzle 4, a long conduit 6, a rotating shaft seat 7, a rotating shaft 8, and a rotating nozzle 9 , a position sensor bracket 10, a signal plate 11, a drive mechanism 12 and a short conduit 21; on both sides of the bottom of the crossbeam of the gantry 1, a plurality of pairs of fixed nozzle long brackets 3 and fixed nozzle short brackets 5 are symmetrically installed, and on the fixed nozzle long brackets 3 and the fixed nozzle short bracket 5 are installed with a fixed nozzle 4 with a rotating screw rod 14 and a nut 13, and a driving mechanism 12 is installed in the middle of the crossbeam bottom of the gantry 1, and the rotating shaft 8 passes through the central hole of the driving mechanism 12, and the rotating shaft 8 Two rotating shaft seats 7 are assembled at the two ends of the two rotating sh...

Embodiment approach 2

[0027] A liquid spraying device, on the basis of Embodiment 1, wherein the spraying angles of the nozzles 4 and 9 are 12 degrees; the beam of the gantry 1 is 4000 mm from the ground; the horizontal distance between the long brackets 3 of the fixed nozzles is 3120 mm, The horizontal spacing of fixed nozzle short bracket 5 is 2720mm, the horizontal spacing of rotating nozzle 9 is 575mm; the length of fixed nozzle long bracket 3 is 800mm, the length of fixed nozzle short bracket 5 is 400mm, the axis of rotating nozzle 9 is 1 The bottom surface of the beam is 100mm; the angle between the nozzle connected to the fixed nozzle long bracket 3 and the vertical direction is 59 degrees, and the angle between the nozzle connected to the fixed nozzle bracket 5 and the vertical direction is 60 degrees; Turn 30 degrees in the direction of travel to spray the front of the compartment, and turn 30 degrees in the opposite direction of the travel of the compartment to spray the rear of the compar...

Embodiment approach 3

[0030] A liquid spraying device. On the basis of Embodiment 1, a set of nozzles of the same specification are added to the existing nozzle positions, so that the spraying amount of liquid is double that of Embodiment 1, and it is suitable for , Spraying on the inner wall of the train car with a cross-section of 3000mm wide and 2000mm high when the spraying amount is required to be larger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com