Multi-thread contact structure prestressing steel strand combination twisting device

A technology of prestressed steel strand and contact structure, applied in textiles, papermaking, textile cables, etc., can solve the problems of low production efficiency and many processes, and achieve the effect of reducing investment costs, saving plant area and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

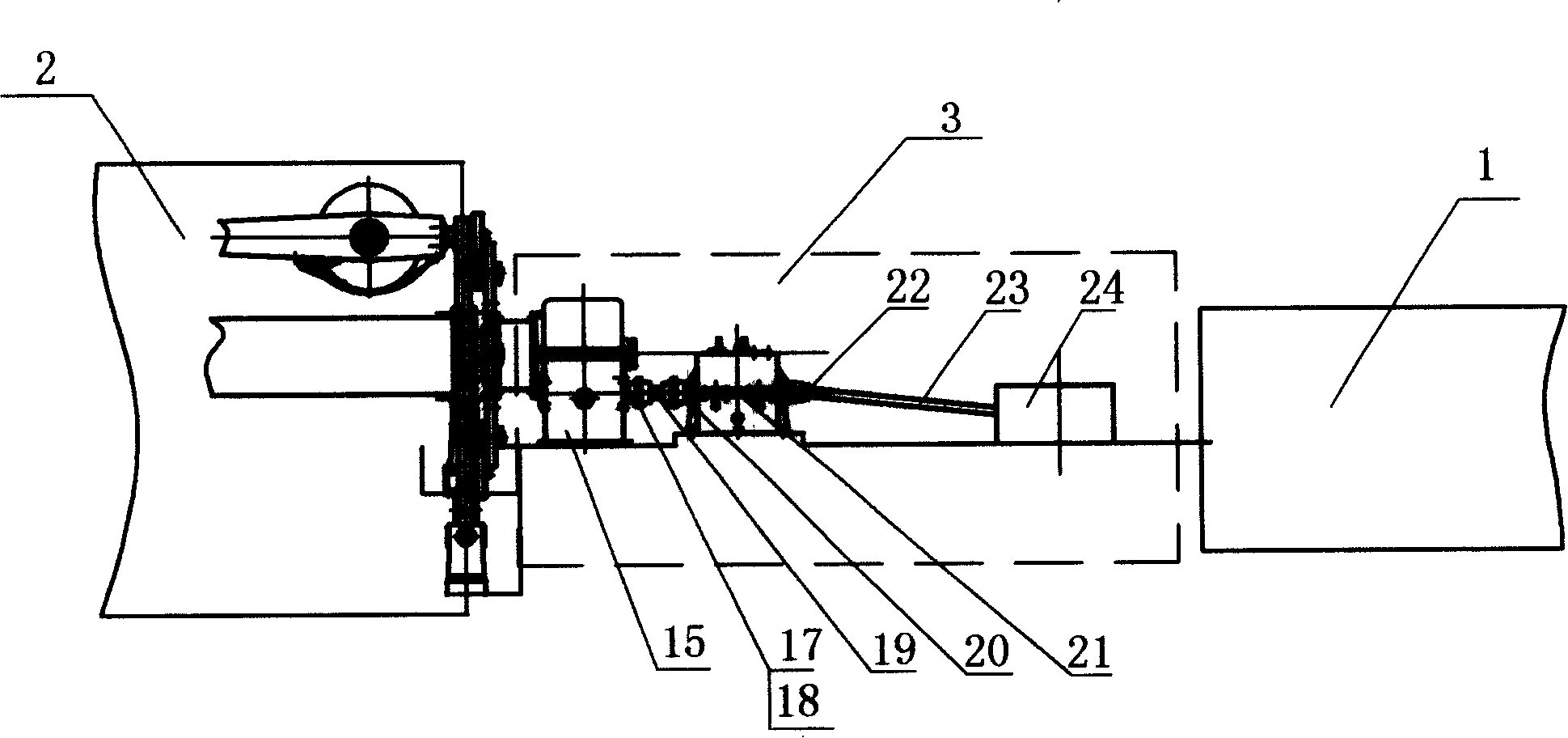

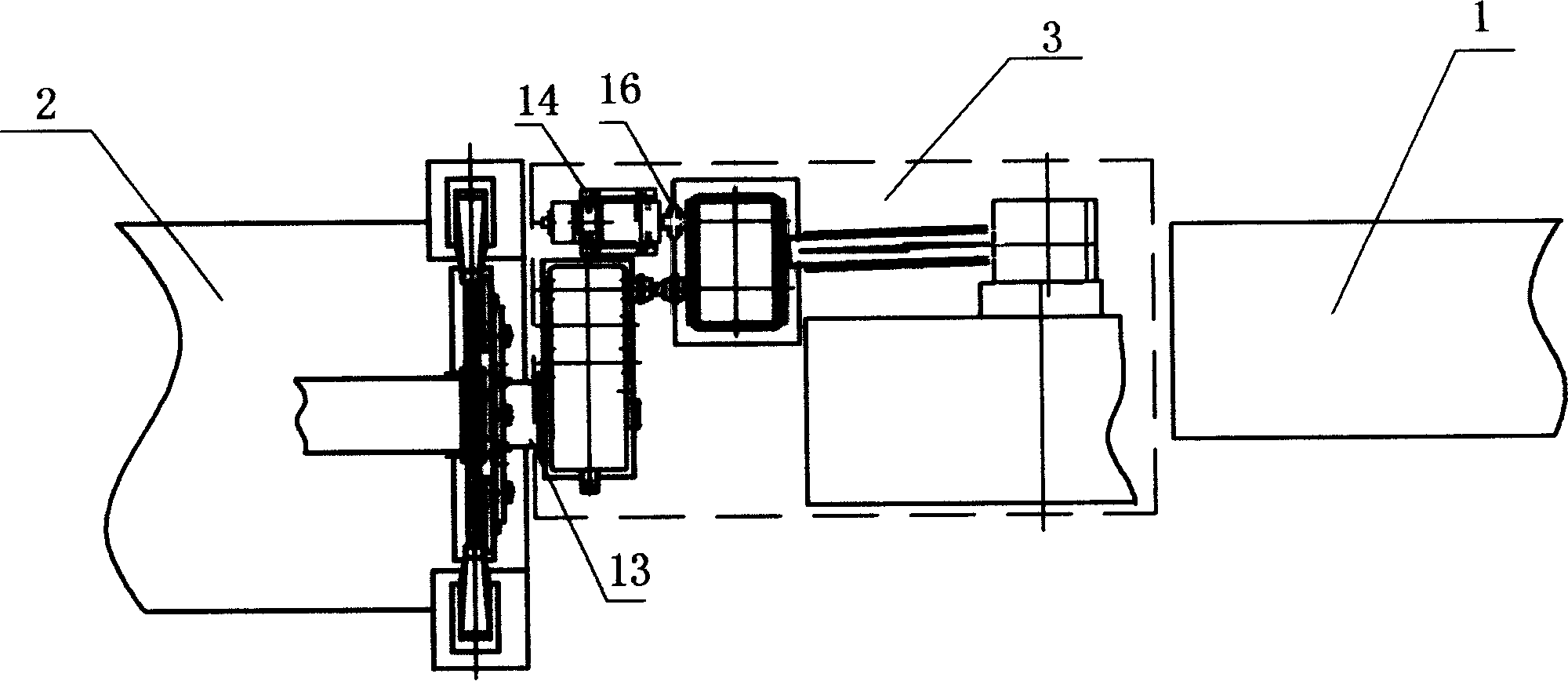

[0009] The multi-wire contact structure prestressed steel strand combined twisting equipment structure involved in the present invention, the specific implementation mode will be described in detail in conjunction with the accompanying drawings:

[0010] It consists of a set of skip-rope or tubular stranding machine 1 and a set of basket-type stranding machine 2. The speed change mechanism 3 connects two sets of different stranding machines in series. After series connection, the two machines are synchronized. The whole machine Coordination and matching, single machine can operate independently, and combined machine can be combined to operate; skipping rope or tubular machine 1 is equipped with seven I-shaped wheels, and can produce 1×7 structural steel strands when used independently; basket-type stranding machine 2 Twelve basket racks are installed, and twelve I-shaped wheels and skipping rope or tubular stranding machine 1 are installed in series to form a set of steel stran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com