LED baking molding method, oven and oven combination

A technology of light-emitting diodes and ovens, applied in drying, dryer, furnace types and other directions, can solve the problems of high energy consumption, increase equipment area, increase power consumption, etc., so as to improve baking quality and reduce production. Cost and effect of reducing plant area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

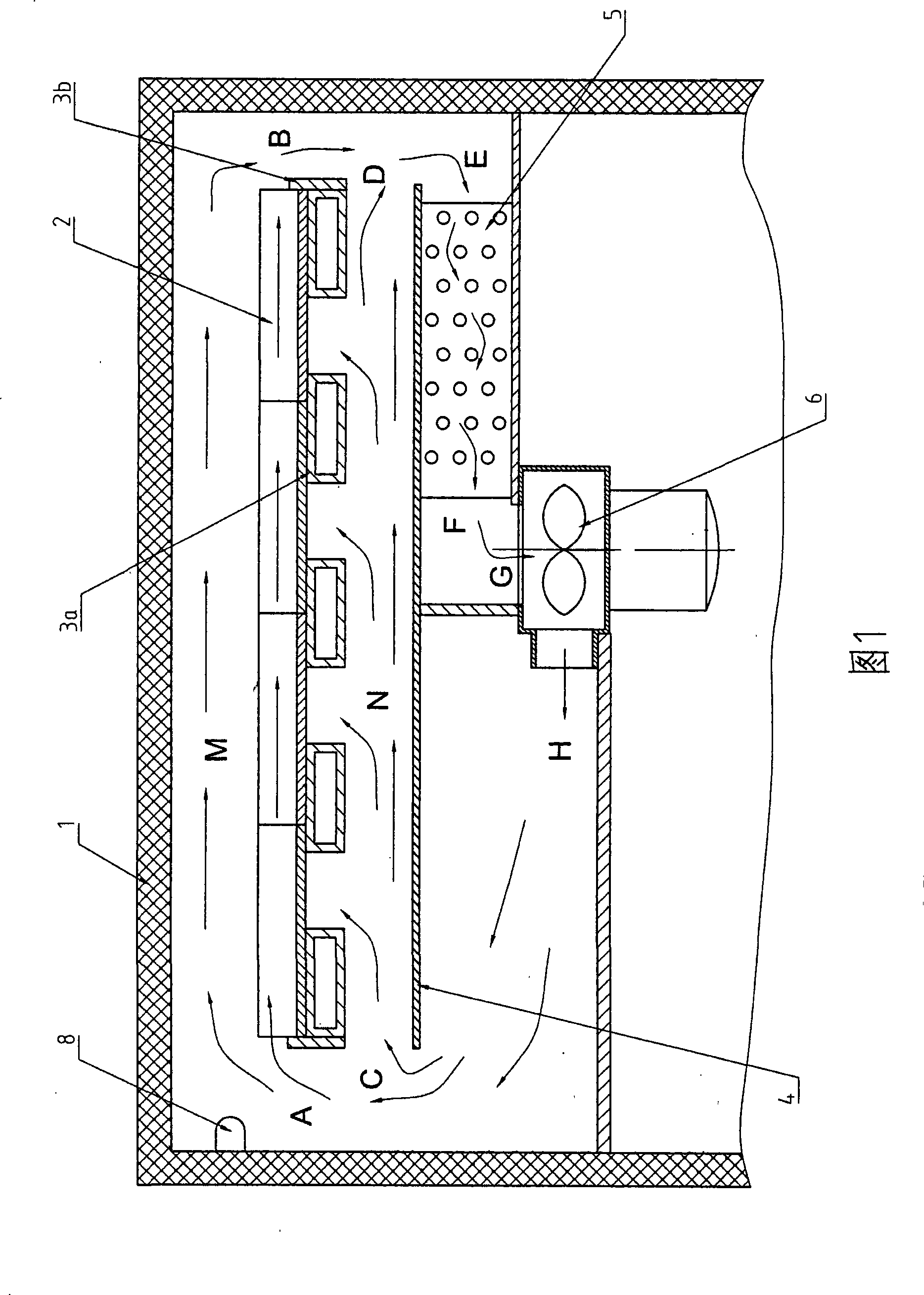

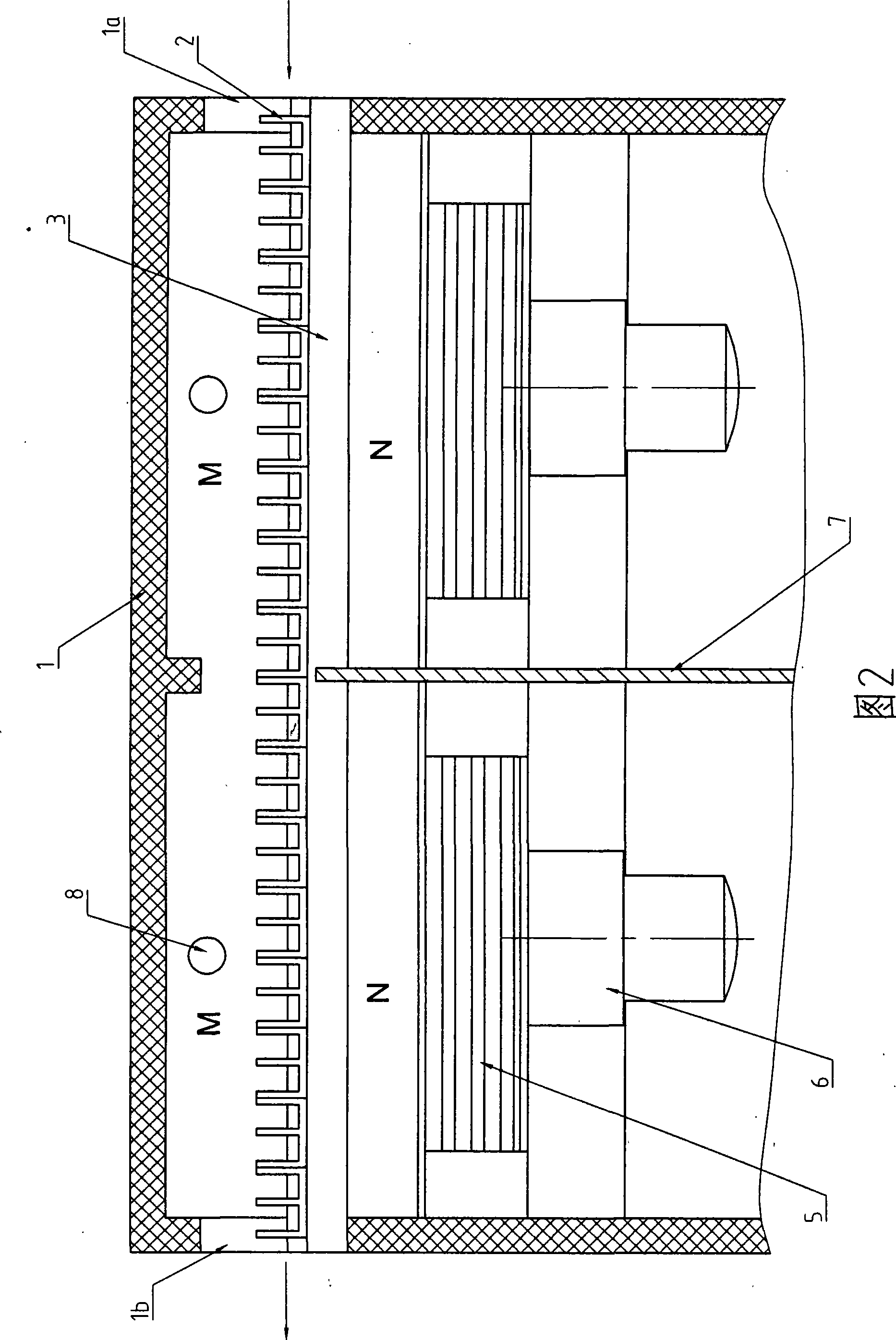

[0023] In the inventive embodiment of the oven shown in Fig. 1 and Fig. 2, the oven comprises a box body 1, the two ends of the box body have an inlet 1a and an outlet 1b of an aluminum boat 2, and a longitudinal beam 3 supporting the aluminum boat extends from the inlet 1a To the exit 1b, the longitudinal girder forms the track of 4 rows of aluminum boats, and the width of the track is equivalent to the width of 4 rows of aluminum boats paralleled horizontally. The width between the inner walls of the box body 1 is greater than the width of the longitudinal beam 3, the air inlet A of the hot gas passage M above the longitudinal beam is formed between the left side of the longitudinal beam 3 and the inner wall of the box body 1, and the right side of the longitudinal beam 3 and the inner wall of the box body 1 The air outlet B of the hot air channel M above the stringer is formed between the inner walls of the stringer, and the hot air flow in the hot air channel M above the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com