A flat converter and its making method

A commutator and flat-plate technology, applied in the field of flat-plate commutator and its preparation, can solve the problems of reduced cross-sectional area of support body, complicated production process, unfavorable mold release, etc., to reduce requirements and production costs. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but it should be noted that these embodiments are only used to illustrate the method of the present invention, rather than limiting the scope of the present invention thereto.

[0026] The structure of the flat plate commutator of the present invention will be illustrated and described below.

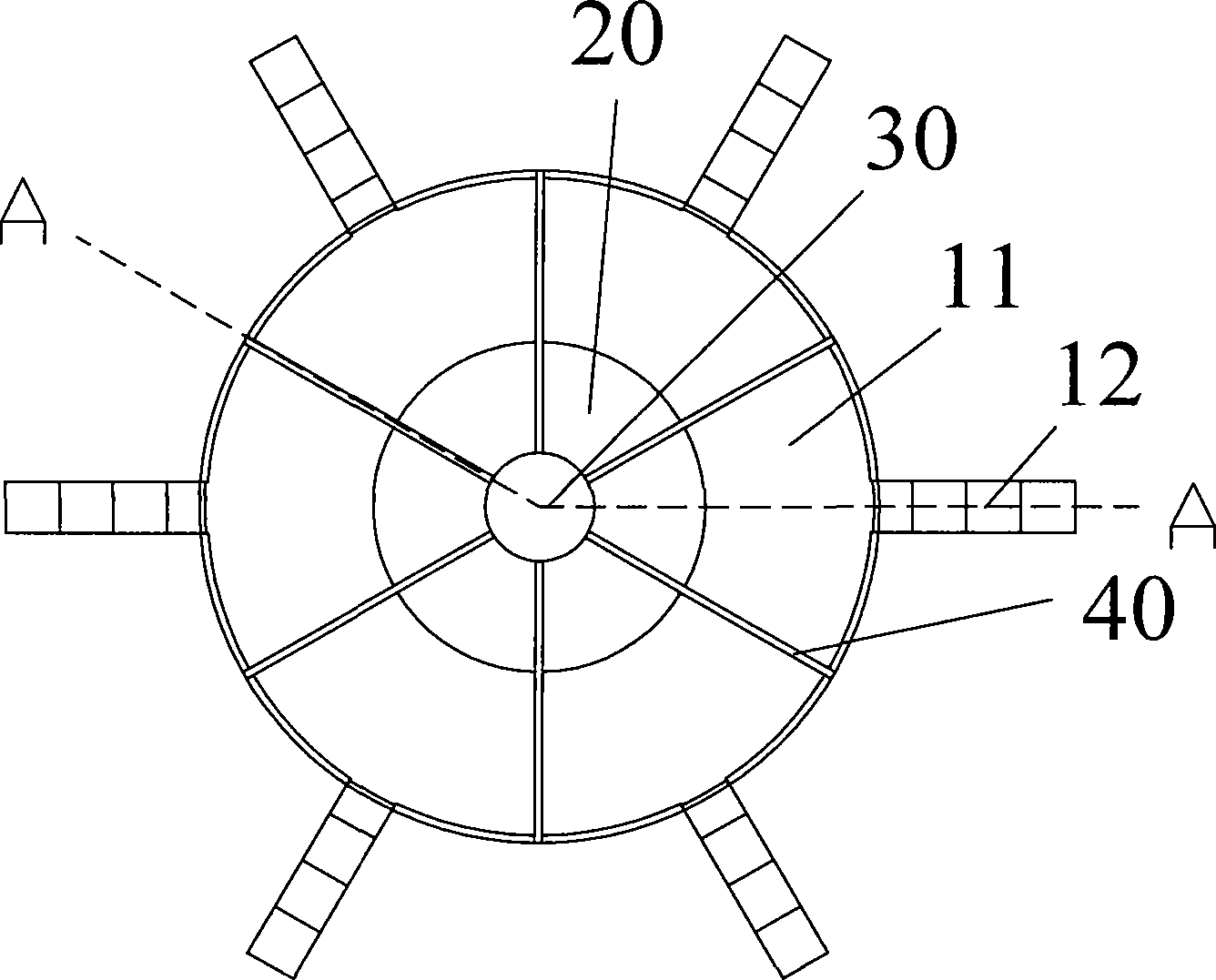

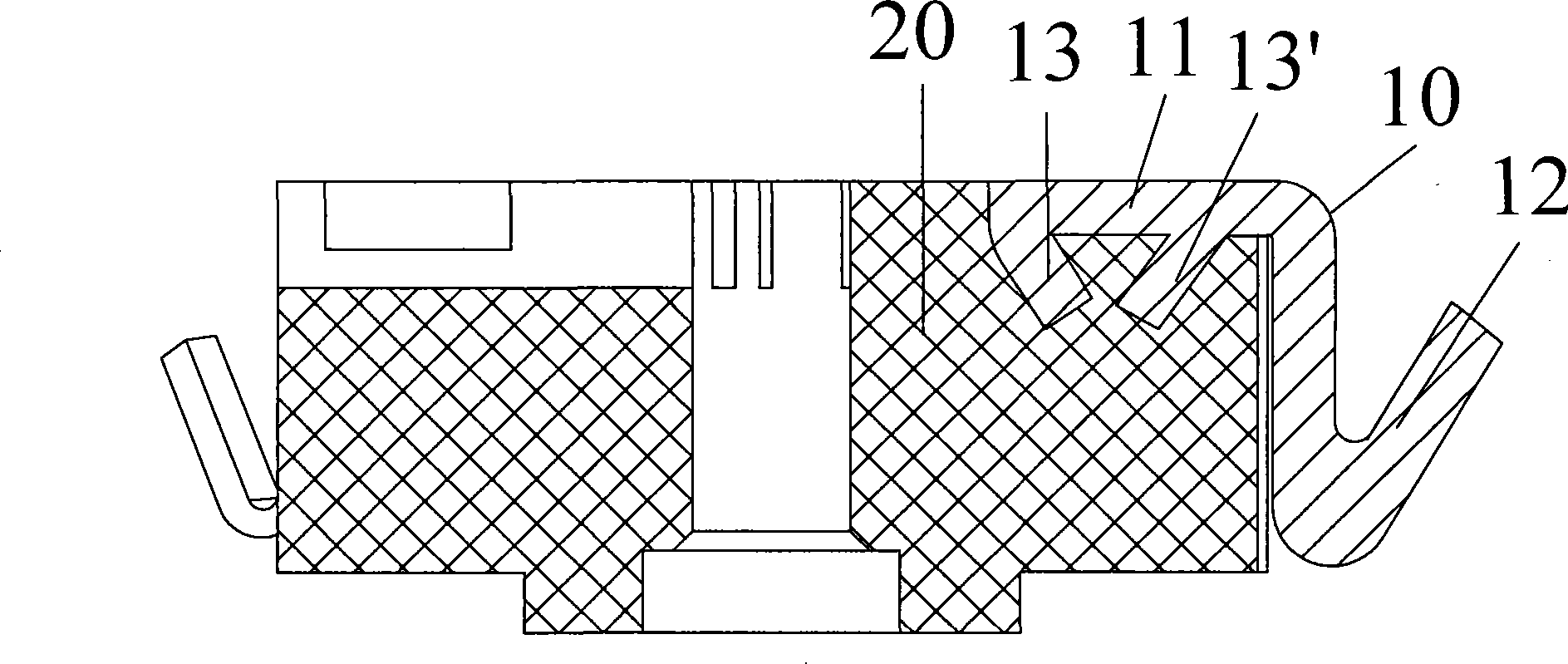

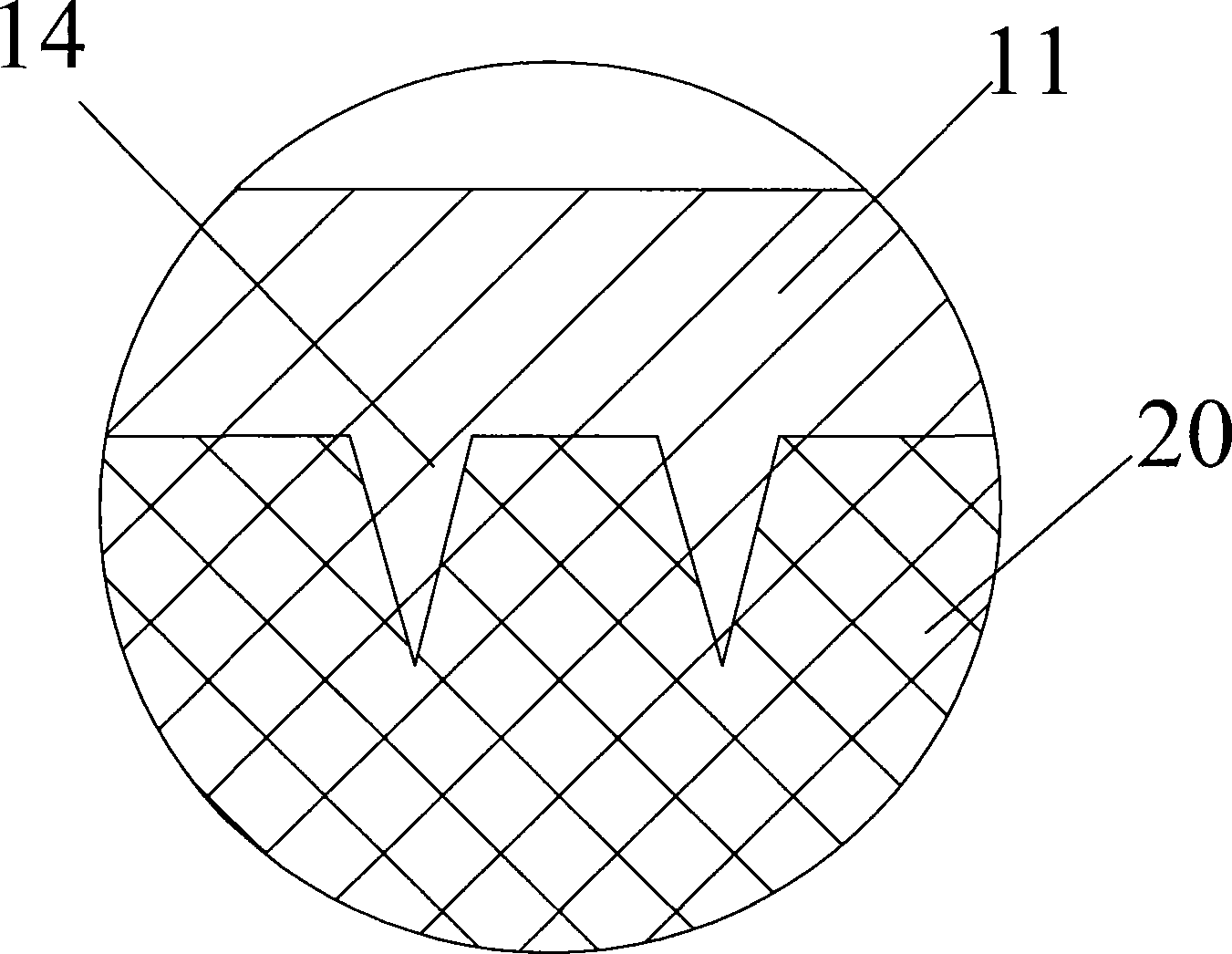

[0027] The flat commutator of the present invention mainly includes: an insulating support body 20 with a central axis hole 30, and a commutator body disposed on the end face of the support body 20, and the commutator body includes a plurality of commutator segments 10 , each of the commutator segments 10 includes a connecting hook 12 and a contact segment 11, the plane of the contact segment 11 is perpendicular to the central axis hole 30, and there is a radial groove 40 between adjacent commutator segments , to ensure that there is no conductive connection betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com