Apparatus for reeling yarns

A winding device and yarn technology, applied in the field of yarn winding devices, can solve the problems of high cost, inaccuracy, complicated structure of the winding device, etc., and achieve the reduction of manufacturing cost and space size, and the accuracy of control. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

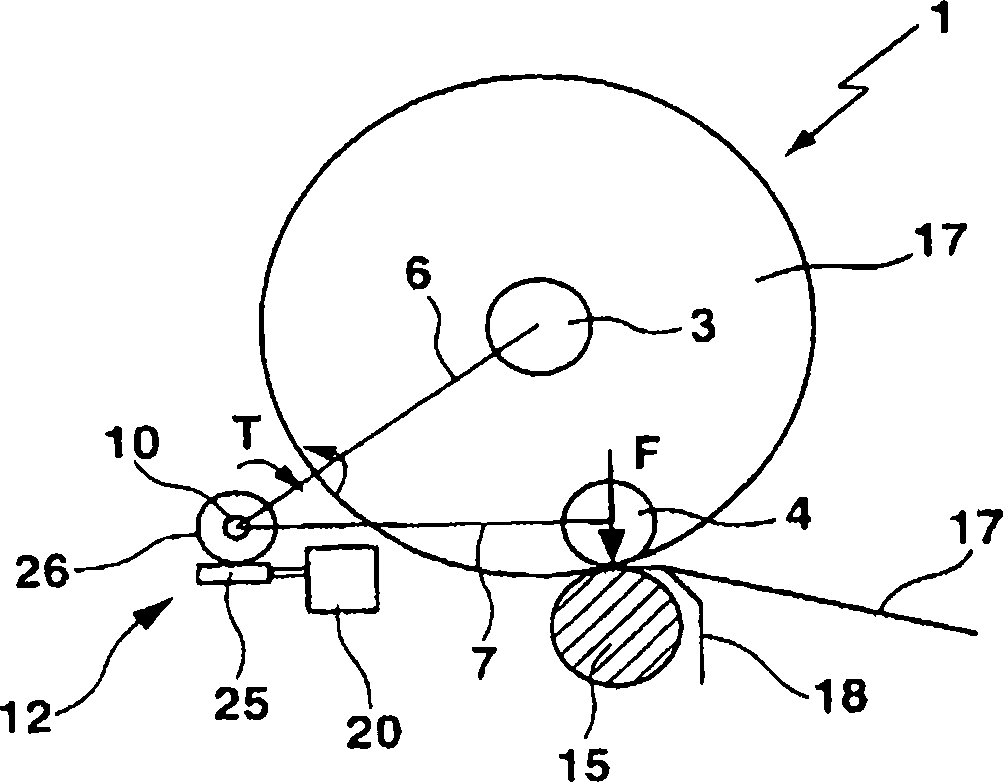

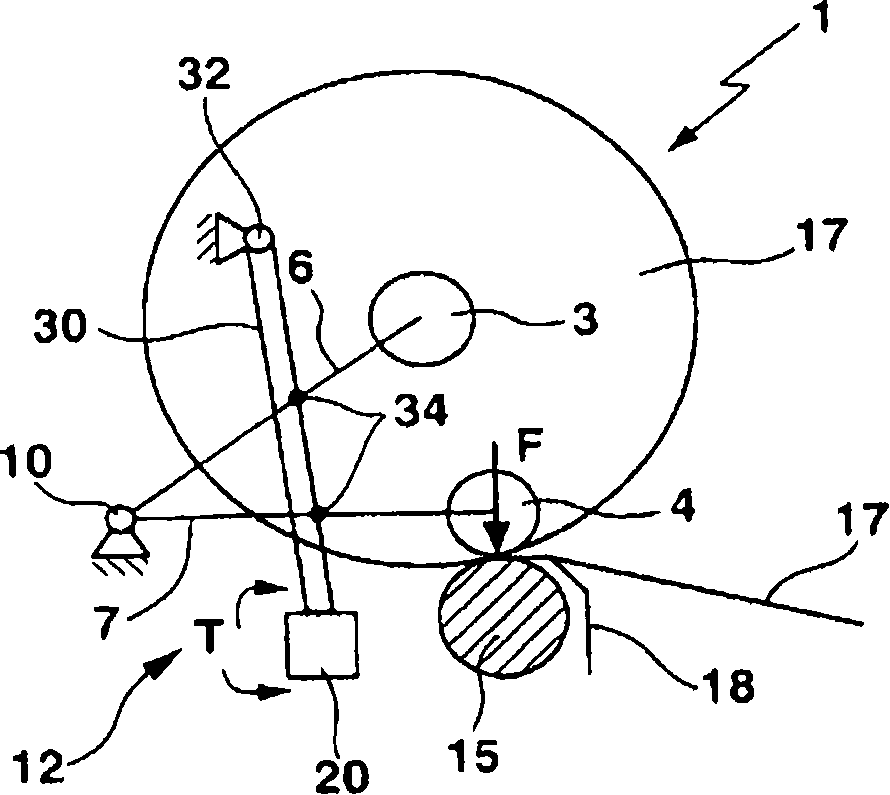

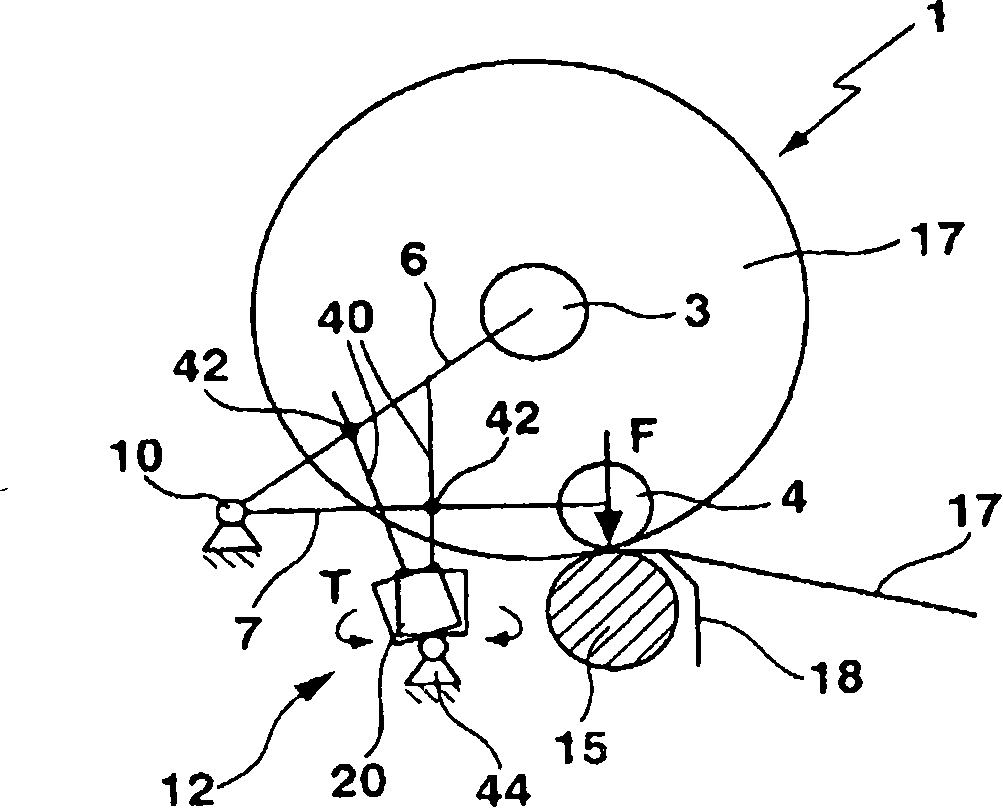

[0027] The figures represent the subject matter of the invention very schematically and are not to be understood to scale. The individual parts of the inventive subject matter are shown so that its structure is well shown.

[0028] exist Figure 1-4 In , the winding machine 1 of the invention is shown accordingly. The yarn holders 3 , 4 are arranged in yarn holder receptacles mounted rotatably about a longitudinal axis. The pressure lever arms 6 , 7 are rotatably fixed in the region of their radially inner ends at the pivot point 10 . The pressure lever arms 6 , 7 are rotatable, ie pivotable, about a pivot point 10 by means of a movable actuator 12 . The yarn holder receiver is arranged rotatably perpendicular to the pressure lever arms 6 , 7 on the outer ends of the pressure lever arms 6 , 7 . The pressure roller 15 supports the yarn holders 3, 4 arranged in the yarn holder receptacle. Thus, the compression roller 15 receives the weight of the compression lever arms 6, 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com