Electric cooker and electric cooker steam barrel flow guiding method

A technology of electric rice cooker and steam cylinder, which is applied in the field of electric rice cooker, can solve the problems of increased manufacturing cost, low mouth-forming rate, and many parts, and achieve the effects of novel structure, simplified assembly process, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

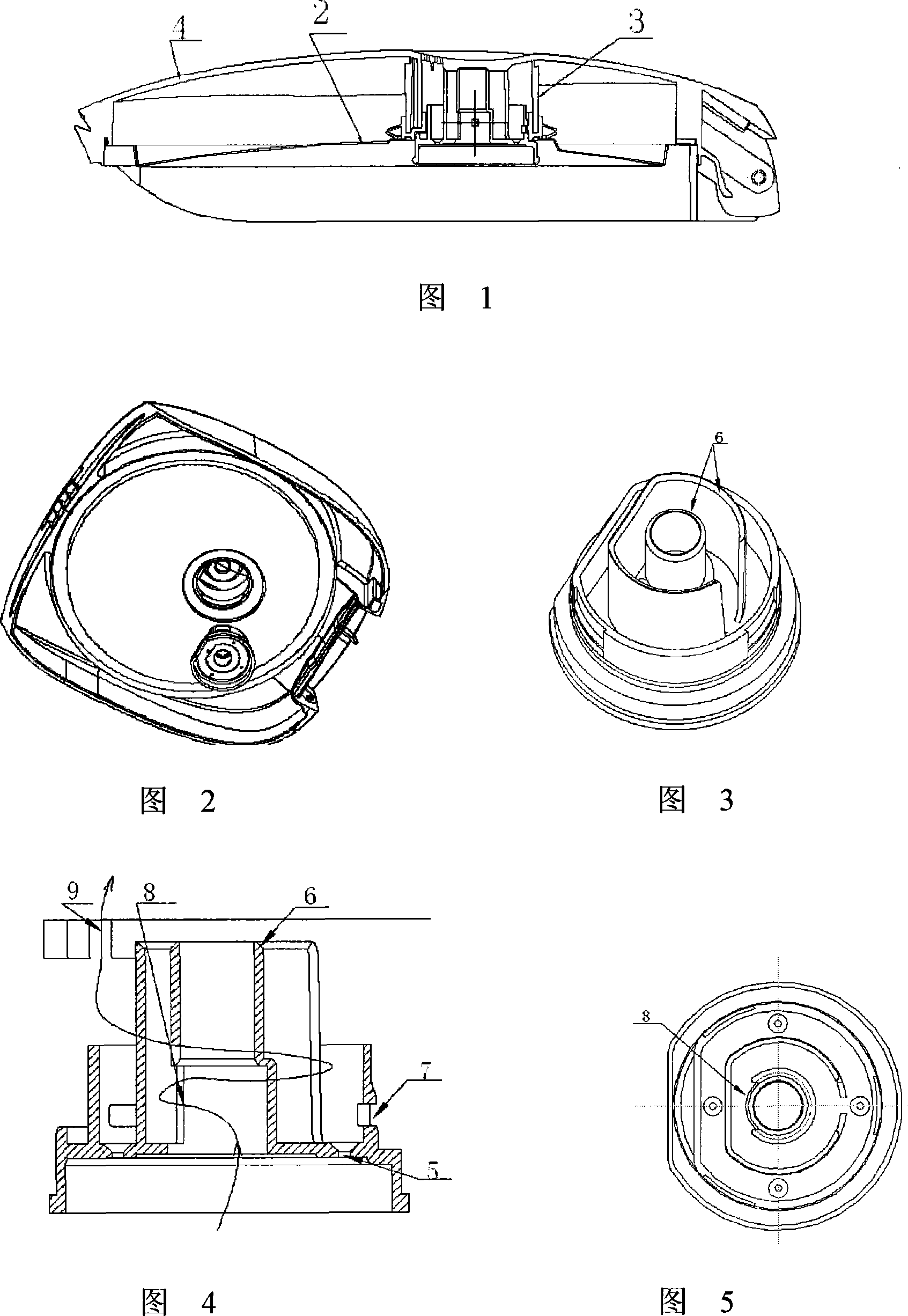

[0013] Embodiment 1: with reference to accompanying drawing 1~5. In the electric rice cooker of this embodiment, the steam drum 3 is installed in the cover of the outer cover 4 of the electric rice cooker, and the upper part of the outer cover 4 of the electric rice cooker 1 is provided with a steam drum 3 , see accompanying drawing 1 . The wall of the second steam diversion circuit in the steam cylinder 3 is provided with a steam cylinder clamping hole 7, the clamping hole 7 is clamped with the steam cylinder installation cylinder wall inside the outer cover 4, and is connected with the heat release by sealing the thermal ring 3 The plates 2 are hermetically bonded, see accompanying drawing 1 . It is located inside the outer cover 4 of the electric rice cooker 1 and the steam outlet of the steam cylinder 3 communicates with the exhaust port 9 of the outer cover. The steam outlet of the steam cylinder 3 communicates with the exhaust outlet 9 of the outer cover 4. See Figure 4...

Embodiment 2

[0015] Embodiment 2: on the basis of embodiment 1, electric rice cooker steam cylinder diversion method, it comprises electric cooker, and steam cylinder is installed in the lid of electric cooker outer cover, and steam cylinder bottom center is provided with steam pipeline and has steam on the wall of pipeline Inlet, steam and rice soup enter the first steam diversion circuit formed around the steam pipe wall from the steam inlet on the steam pipe wall, and under the action of the first steam diversion circuit wall, change the steam and The direction of the rice soup, because the opening of the first steam diversion circuit wall with the opposite steam inlet direction enters the second steam diversion circuit formed around the first steam diversion circuit wall, the steam and rice soup pass through the first steam diversion circuit During the process with the second steam diversion circuit, the flow speed of steam and rice soup decreases, and the steam and water are separated....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com