Hydraulic centering device

A technology of centering device and hydraulic pressure, applied in the direction of guiding/positioning/aligning device, etc., can solve the problems of reducing the quality of strip rolling, roughing of the rolls, and troublesome replacement, so as to improve the rolling efficiency, improve the rolling quality, Easy to adjust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

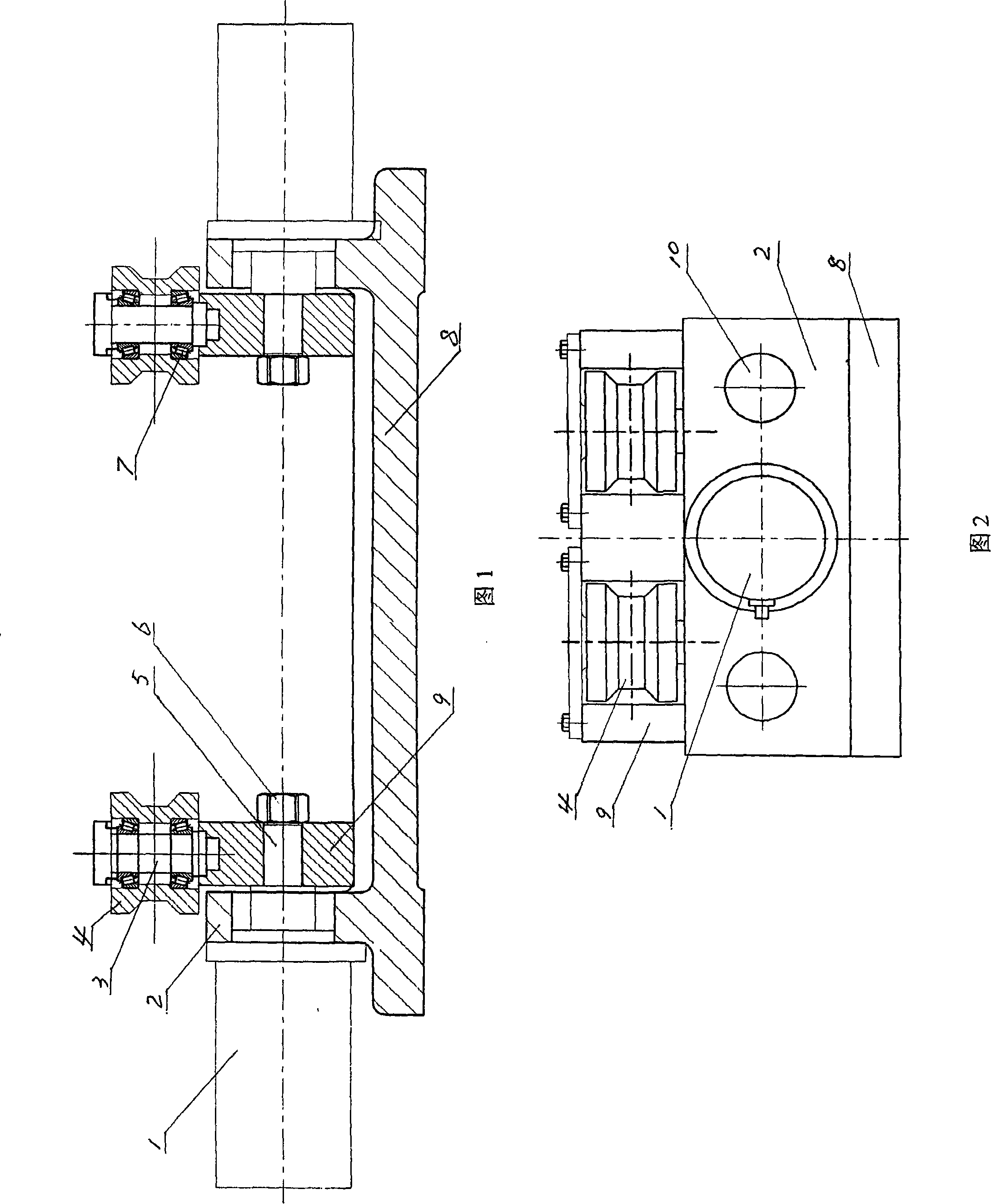

[0012] As shown in Figs. 1 and 2, the hydraulic centering device of the present invention includes a base 8 which is in the shape of a flat plate and two bosses 2 are provided on it. The two bosses are in the shape of a flat plate, and they are arranged upright and oppositely arranged. Their lower sides are integrated with the base 8 and three shaft holes are machined on their lower parts, and the three shaft holes are on the same level. The outer sides of the two bosses 2 are both fixed with an oil cylinder 1, the two oil cylinders are on the same axis, and the ends of their piston rods 5 respectively pass through the middle shaft hole at the lower part of the corresponding boss 2 and then extend into the inner side of the boss 2. A moving plate 9 is provided on the inner side of the two bosses 2, and three shaft holes are machined on the lower part of the moving plate 9, and the three shaft holes correspond to the three shaft holes on both sides of the lower part of the boss. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com