Water-cooling subbase

A water-cooled, molten steel technology, applied in ingot workshops, manufacturing tools, foundry workshops, etc., can solve the problems of easy leakage of steel from ingot molds and flow troughs, and melting loss of ingot molds and ingot trays. Ingot quality, thermal erosion reduction, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

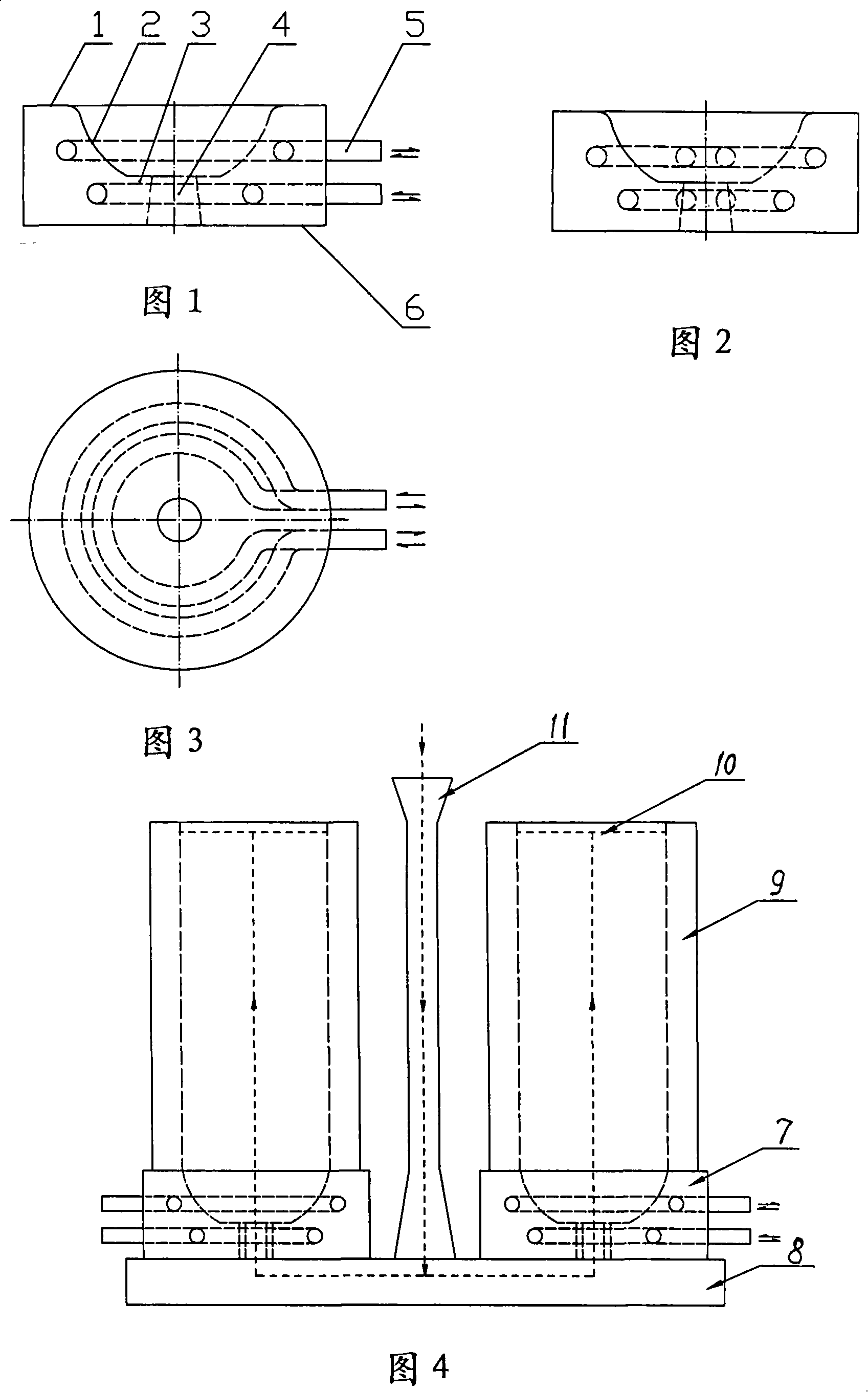

[0017] Referring to Fig. 1 to Fig. 3, a water-cooled base of the present invention has an upper plane 1 and a lower plane 6, the middle part of the base is concave, and a molten steel injection hole 4 is provided at the bottom of the concave.

[0018] A cooling upper chamber 2 and a cooling lower chamber 3 are arranged inside the water-cooled base between the upper plane 1 and the lower plane 6 . The upper cooling chamber 2 and the lower cooling chamber 3 are respectively composed of one or more layers of cooling pipes, and the two ends of the cooling pipes extend outward and expose the nozzle 5 . Cooling water enters the cooling upper chamber 2 and the cooling lower chamber 3 from the nozzle 5 .

[0019] The cooling upper chamber 2 and the cooling lower chamber 3 can be composed of one or more layers of cooling pipes. For example, the cooling pipes for cooling the upper chamber 2 are composed of two or three layers of cooling pipes, and the cooling pipes for cooling the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com