Inflatable pneumatic tyre

A technology of pneumatic tires and tires, which is applied to tire parts, tire sidewalls, transportation and packaging, etc., and can solve the problems of reducing appearance and difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

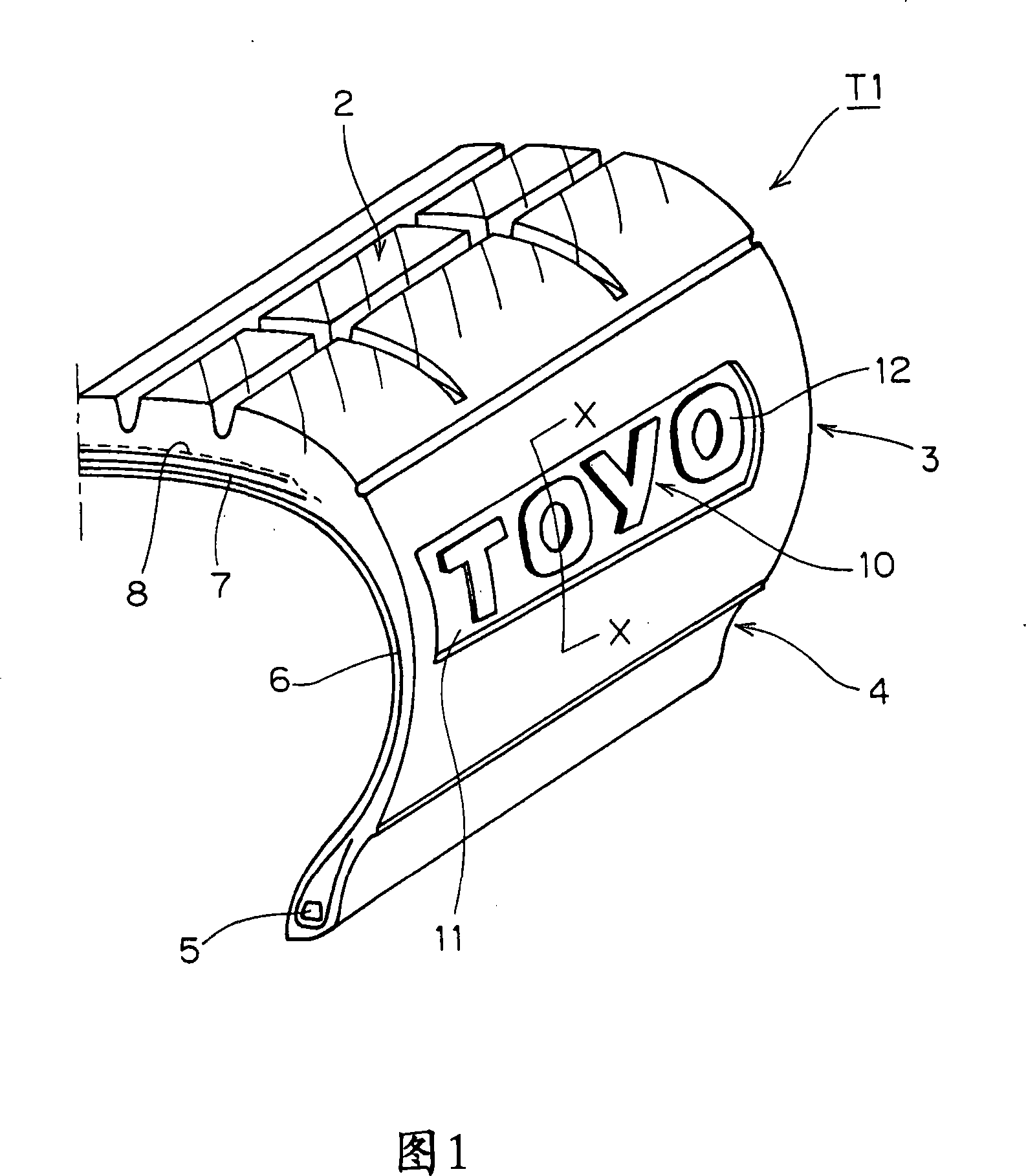

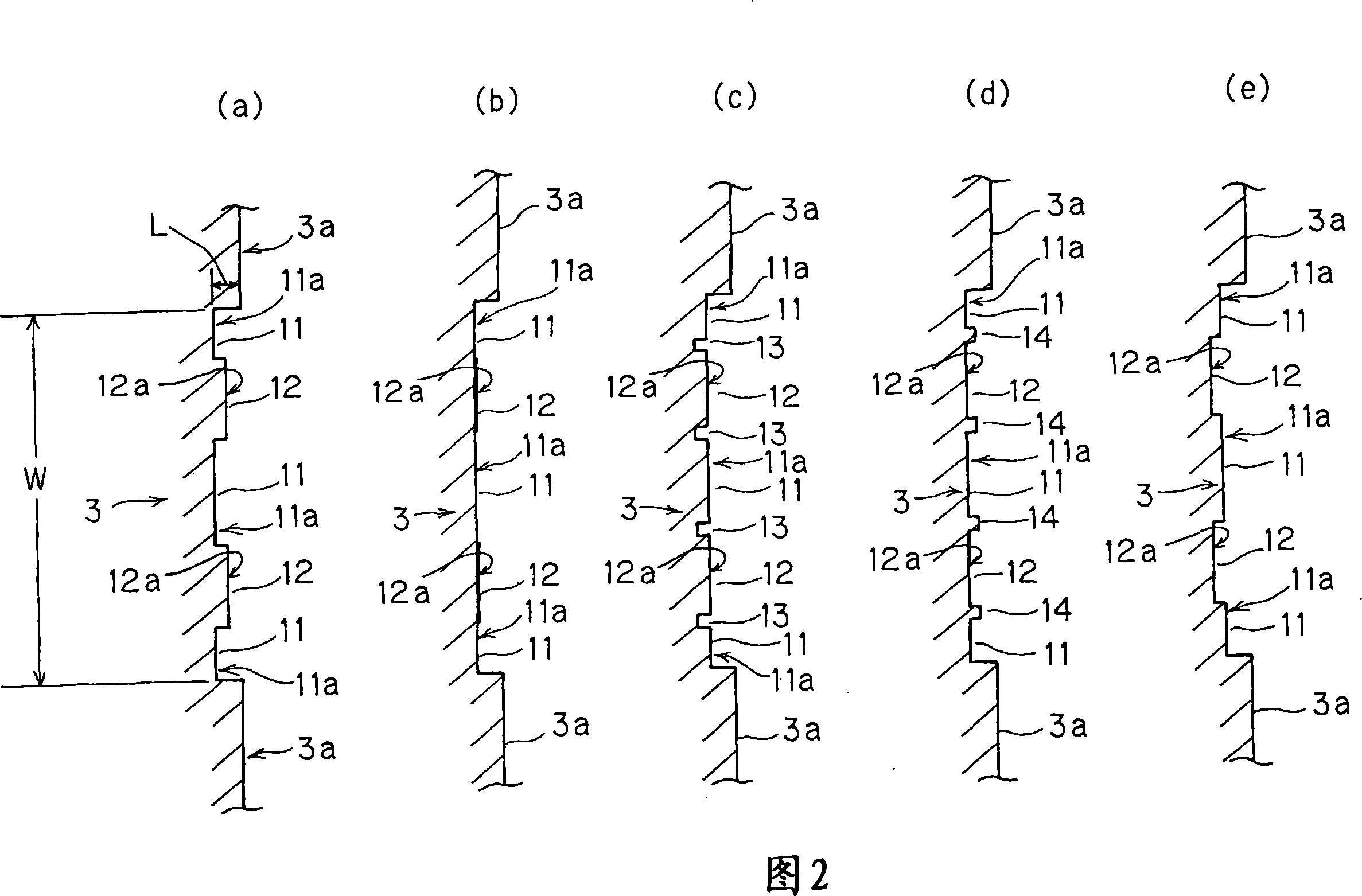

[0036] 1 is a perspective view of a half section of a tire, showing a sidewall surface of a pneumatic tire T1 (hereinafter, the pneumatic tire is simply referred to as a "tire") according to a first embodiment of the present invention, and Figs. 2(a) to (e) It is the X-X line sectional view in Fig. 1. In FIGS. 2( a ) to ( e ), for the sake of convenience, the curved surface of the side wall surface is developed into a plane and shown.

[0037] The tire T1 is composed of a tread portion 2, a sidewall portion 3, and a bead portion 4. The sidewall portion 3 extends outward in the radial direction of the tire from both ends of the tread portion 2; The outer end is connected and fixed to the rim flange. In this example, a radial tire for passenger cars is exemplified, which has a linear structure carcass 6 folded back around the tire bead core 5, a belt layer 7, and a belt reinforcement layer 8. The folded end of the carcass is locked; the belt layer 7 is arranged on the outer pe...

no. 2 approach

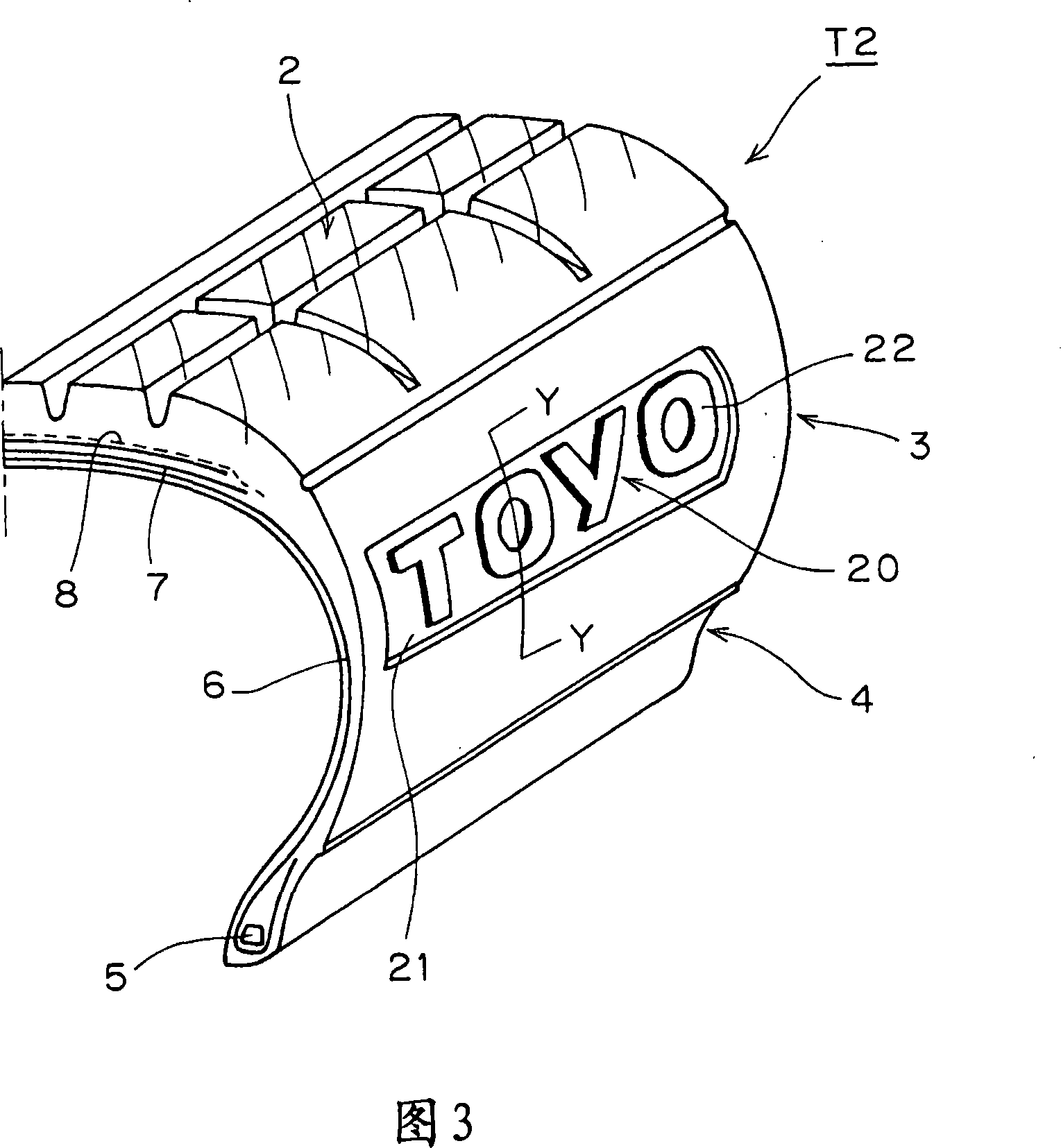

[0062] Fig. 3 is a perspective view of a tire half section, showing a sidewall surface of a tire T2 according to a second embodiment of the present invention. 4( a ) to ( e ) are cross-sectional views along line Y-Y in FIG. 3 . In FIGS. 4( a ) to ( e ), for the sake of convenience, the curved surface of the side wall surface is developed into a plane and shown.

[0063] The tire T2 is a radial tire for passenger vehicles having the same internal structure as the above-mentioned tire T1 (the same parts and components as the tire T1 are assigned the same symbols), and the name of the manufacturer is indicated on the surface of the side wall 3 of the tire T2. , brand name, tire size, etc. characters, numbers, symbols, or marks 22 used to indicate the rotation direction of the tire, design graphics used to decorate the side, etc. In FIG. 3 , the mark 22 is displayed as a character string (TOYO) as engraved characters.

[0064] Around the mark 22 is provided a background portion ...

no. 3 approach

[0084] Fig. 5 is a perspective view of a tire half section, showing the sidewall surface of a pneumatic tire T3 according to a third embodiment of the present invention, Fig. 6 is a partial sectional view along line X-X in Fig. Partial sectional view of Y-Y line. In FIGS. 6 and 10 , for the sake of convenience, the curved surface of the side wall surface is developed into a plane for representation.

[0085] The tire T3 is composed of a tread portion 2, a sidewall portion 3, and a bead portion 4. The sidewall portion 3 extends outward in the radial direction of the tire from both ends of the tread portion 2; The outer end is connected and fixed to the rim flange. In this example, a radial tire for passenger cars is exemplified, which has a linear structure carcass 6 folded back around the tire bead core 5, a belt layer 7, and a belt reinforcement layer 8. The folded end of the carcass is locked; the belt layer 7 is arranged on the outer periphery of the tread portion 2 of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arithmetic mean surface roughness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com