Sliding form parallel translation concrete lining machine as well as construction method thereof

A technology of parallel movement and sliding formwork, which is applied in the direction of infrastructure engineering, construction, etc., can solve the problems of heavy weight, bulky, and inability to realize cloth vibration, etc., and achieve the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

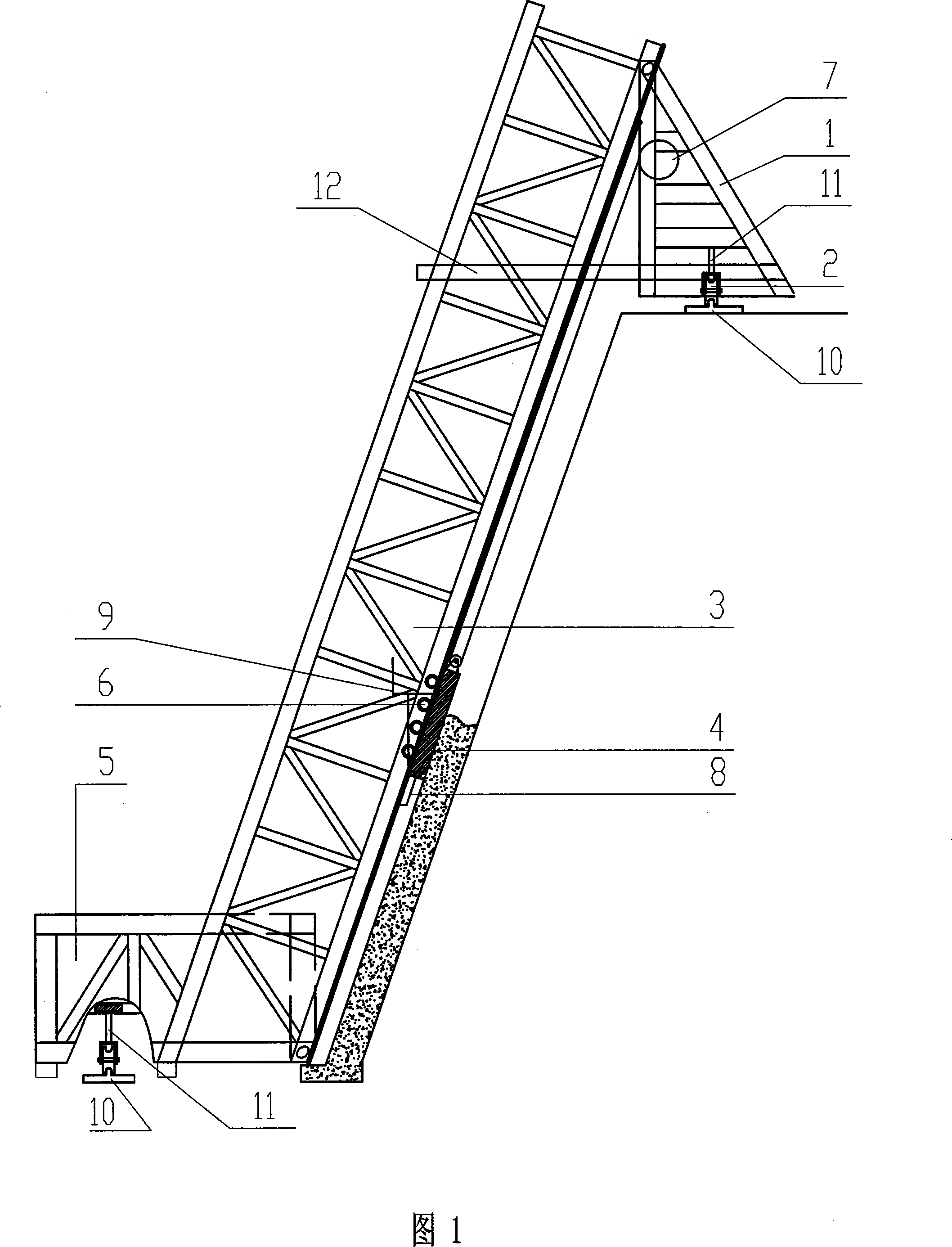

[0028] As shown in Figure 1, the main frame 3 is made of four parallel I-beams as girders, which are welded by angle steel. Track (in addition, the sliding track can also be set on the I-beam), the bearing 6 installed on the sliding formwork 4 corresponds to the sliding track; the main body of the top frame 1 is a triangle, and the I-beam is used as the main frame, and the angle steel is welded On the main frame, a firm structure is formed; a fixed rod 12 is connected between the bottom of the top frame 1 and the main frame 3, and the fixed rod 12 connects the top frame 1 and the main frame 3 into a stable tripod structure. Two motor-driven winding mechanisms 7 are installed at the bottom of the top frame 1, the wire rope on the winding mechanism 7 is connected with the sliding formwork 4, and the top of the top frame 1 is hinged with the main frame 3 through pins; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com