Automatic sequence flushing-water method of flush toilet and automatic sequence flushing-water device

An automatic sequence, flush toilet technology, applied in the field of sanitary ware, can solve the problems of hygienic risks, poor visual sense, poor operability, low cleanliness, etc., and achieves the effects of convenient industrial production, easy production, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

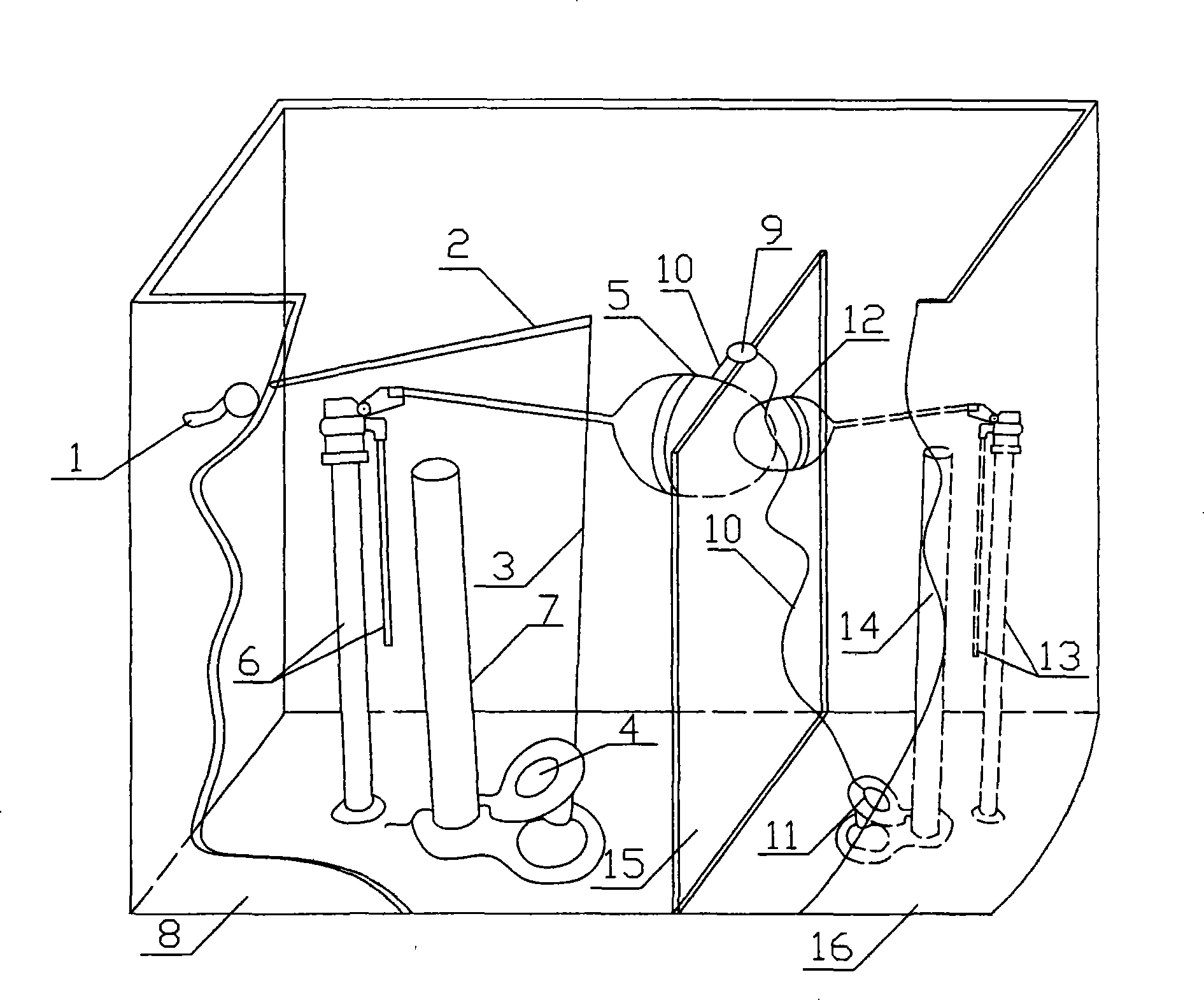

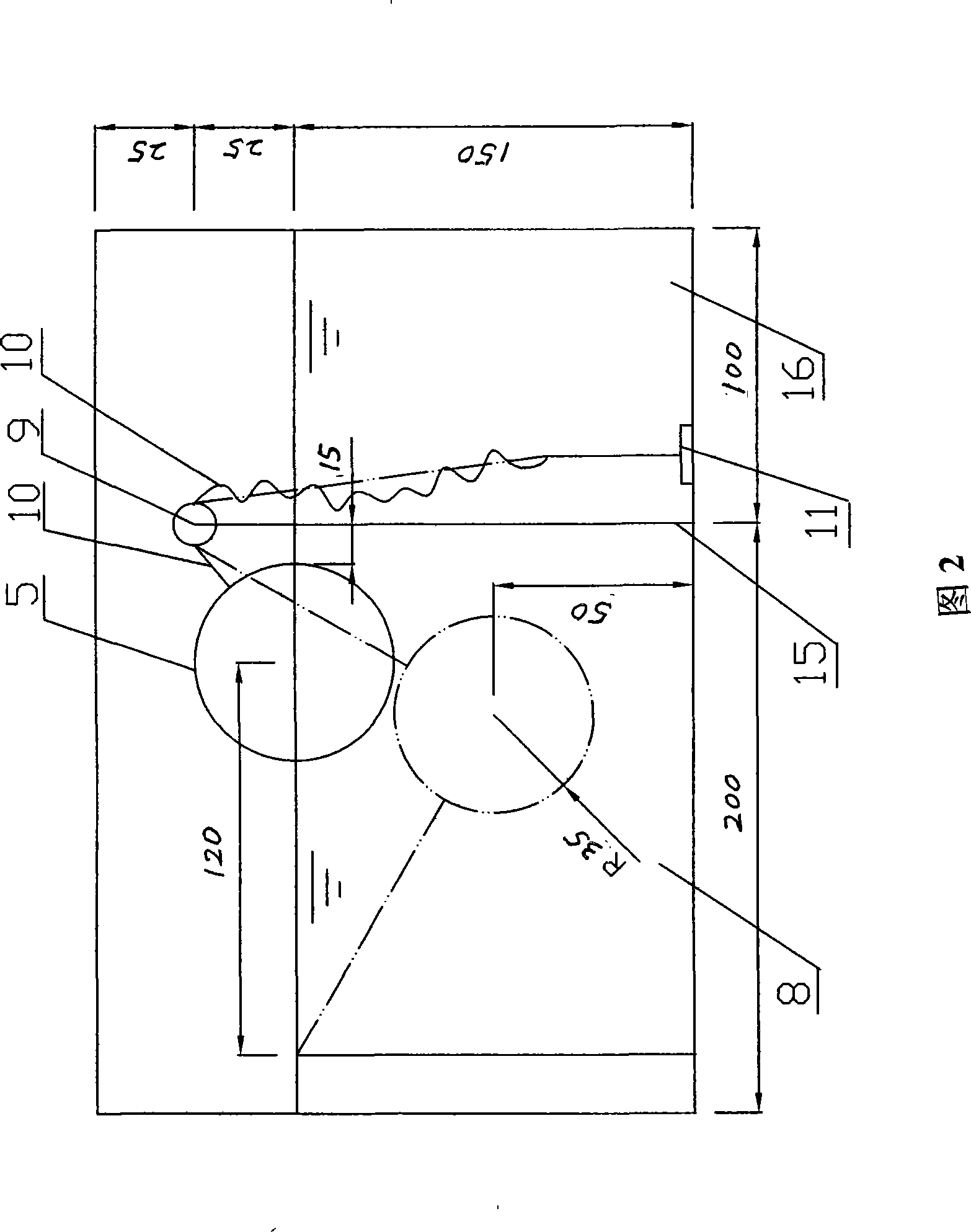

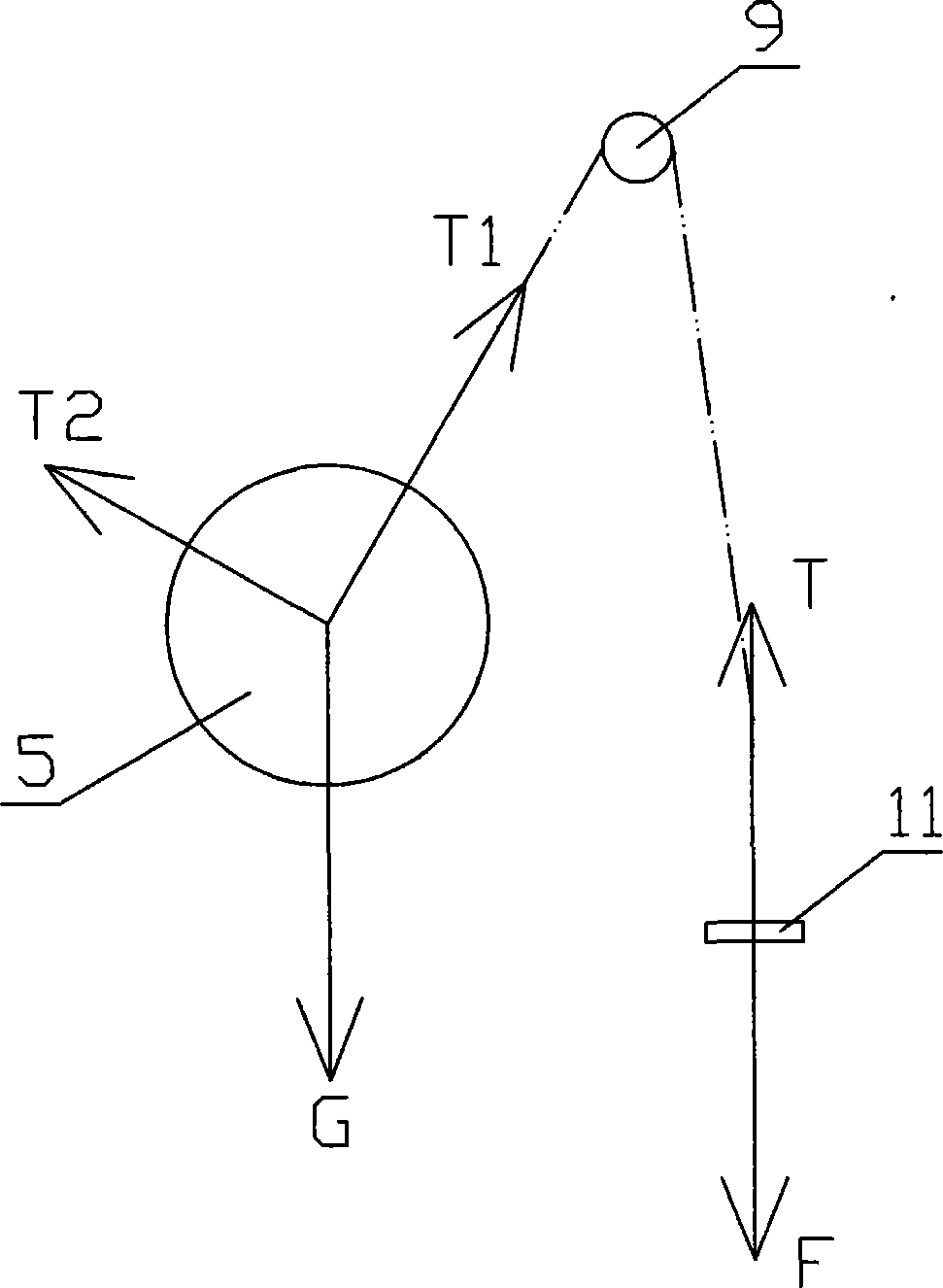

[0022] In this embodiment, the structure of the sequential flushing device of the toilet is as follows: figure 1 As shown, it includes a reclaimed water tank 8, a clean water tank 16, a flushing start handle 1, a sequential flushing control mechanism, a reclaimed water inlet pipe 6 installed in the reclaimed water tank, a reclaimed water overflow pipe 7, a reclaimed water inlet control mechanism and a reclaimed water The flushing control mechanism, the clean water inlet pipe 13 installed in the clean water tank, the clean water overflow pipe 14, the clean water inlet control mechanism and the clean water flushing control mechanism. The reclaimed water flush control mechanism is composed of a lever I2, a pull wire I3, and a leather plug I4. The lever I2 is hinged to the tank wall of the reclaimed water tank 8. One end of the lever I2 is connected to the flush start handle 1, and the other end is connected to the pull wire I 3 is connected, and the pull wire I 3 is connected wit...

Embodiment 2

[0044] In this embodiment, the structure of the double-tank sequential flushing device used for flush toilets is as follows: Figure 4 shown. The difference from Embodiment 1 is that the sequential flushing control mechanism is a lever structure, which is composed of a lever II 17 and a pull wire III18 connected to both ends of the lever II. On the plate 15; the stay wire III18 at one end of the lever II is connected with the float I 5 of the float valve located in the middle water tank, and the stay wire III18 at the other end of the lever II is connected with the leather plug II 11 in the clean water tank.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pull | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com