Folding switching house cover

A steel roof and H-shaped steel technology, applied in roofs, building components, buildings, etc., can solve problems such as high cost and complexity, and achieve the effects of low cost, clear force transmission mechanism, and simple design and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

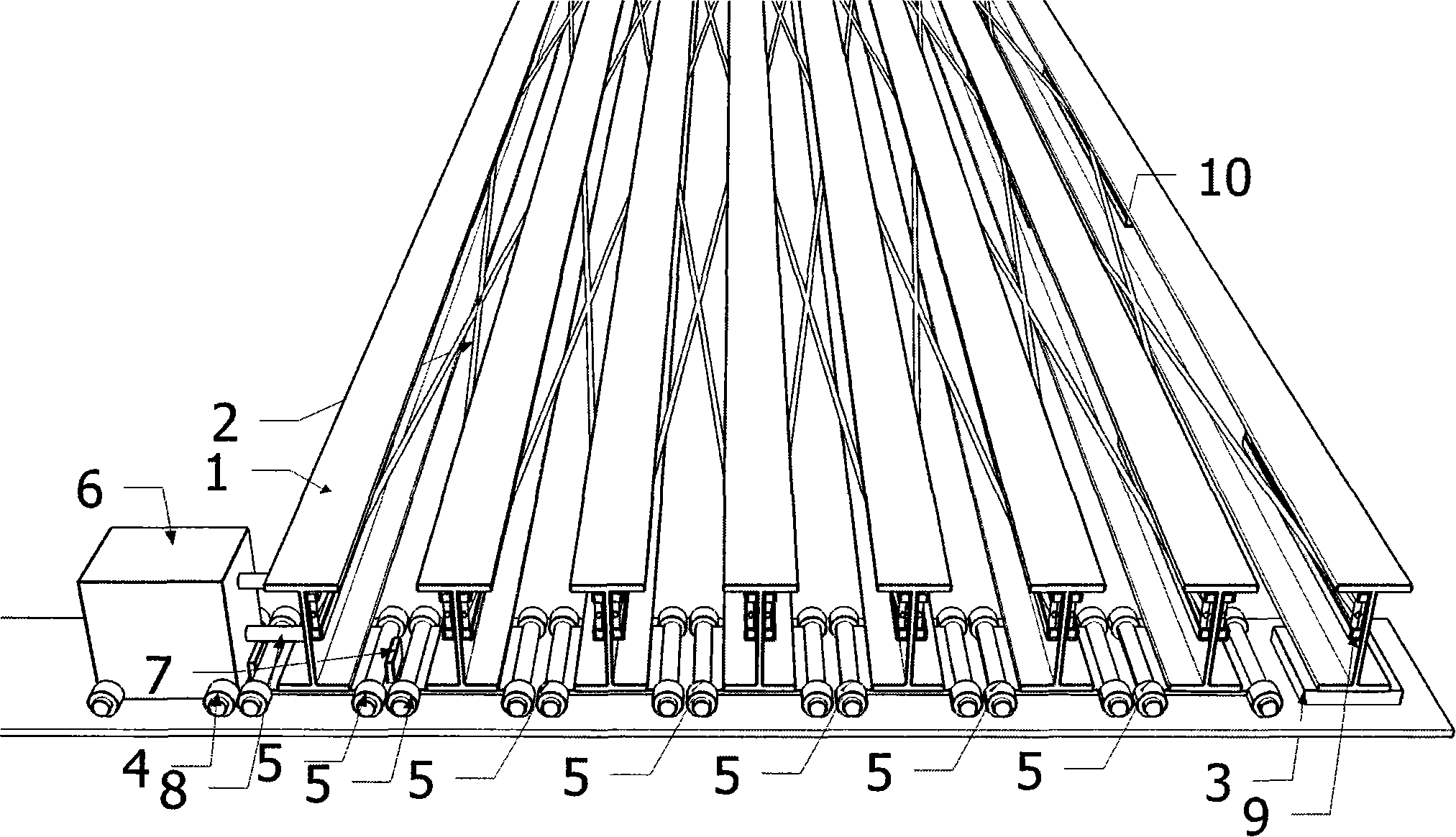

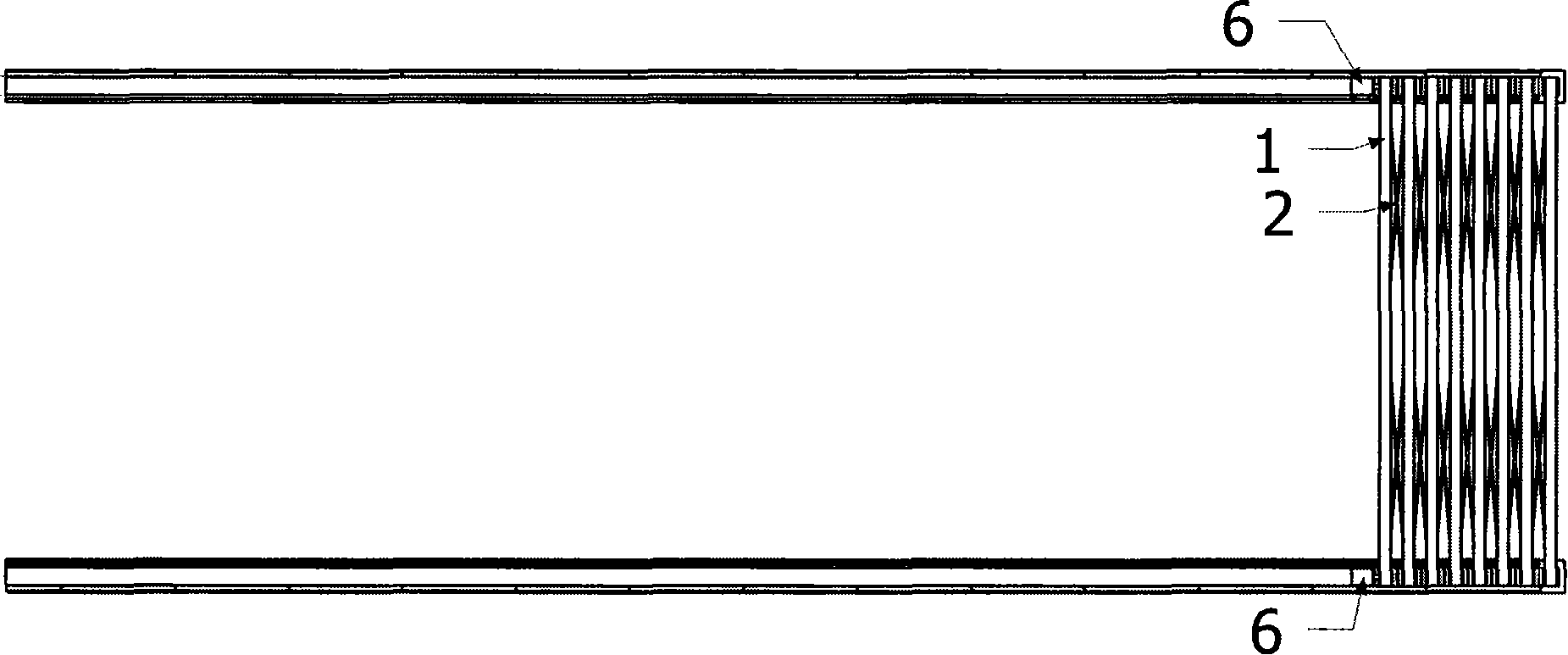

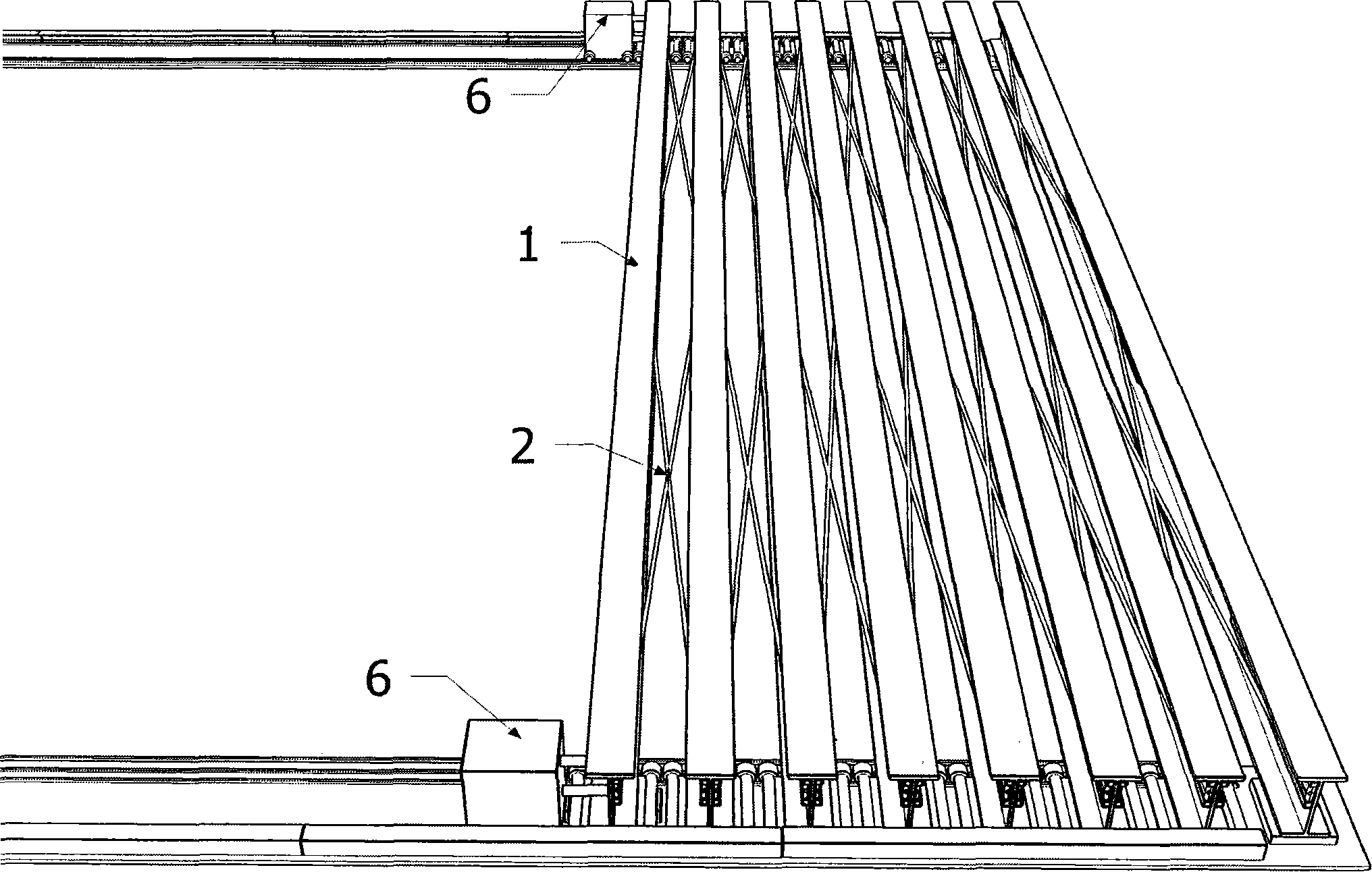

[0037] Such as figure 1 As shown, the folding and closing roof includes H-shaped steel beams 1, horizontal cross braces between beams 2, fixed nodes at beam ends 3, driving wheels 4, rolling nodes at beam ends 5, driving devices 6, retractable stop steel plates 7, connecting Rod 8, H-shaped steel beam end sliding track 9, H-shaped steel beam middle sliding track 10, rotating rod 13 and steel ball 14, welded H-shaped steel plate member 15, pin shaft 16, roof support member 17, guide rail for beam running And the track 20 on which the beam runs; the H-shaped steel beam 1 can be any one of ordinary welded H-shaped steel, hot-rolled H-shaped steel or high-frequency welded H-shaped steel, and can also be in the form of a square steel pipe or a box section; The horizontal cross support 2 between the beams, the connecting rod 8 and the rotating rod 13 are all made of round steel pipes; the two ends of the H-shaped steel beam at the outermost end of the roof are respectively welded an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com