Improvement of LED display floor structure

A technology with the same floor and structure, which is applied in the improvement field of LED display floor structure, can solve the problems of short circuit of internal electrical components, insufficient surface bearing capacity, damage, etc., and achieve the effect of prolonging service life, avoiding short circuit and damage, and improving load bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

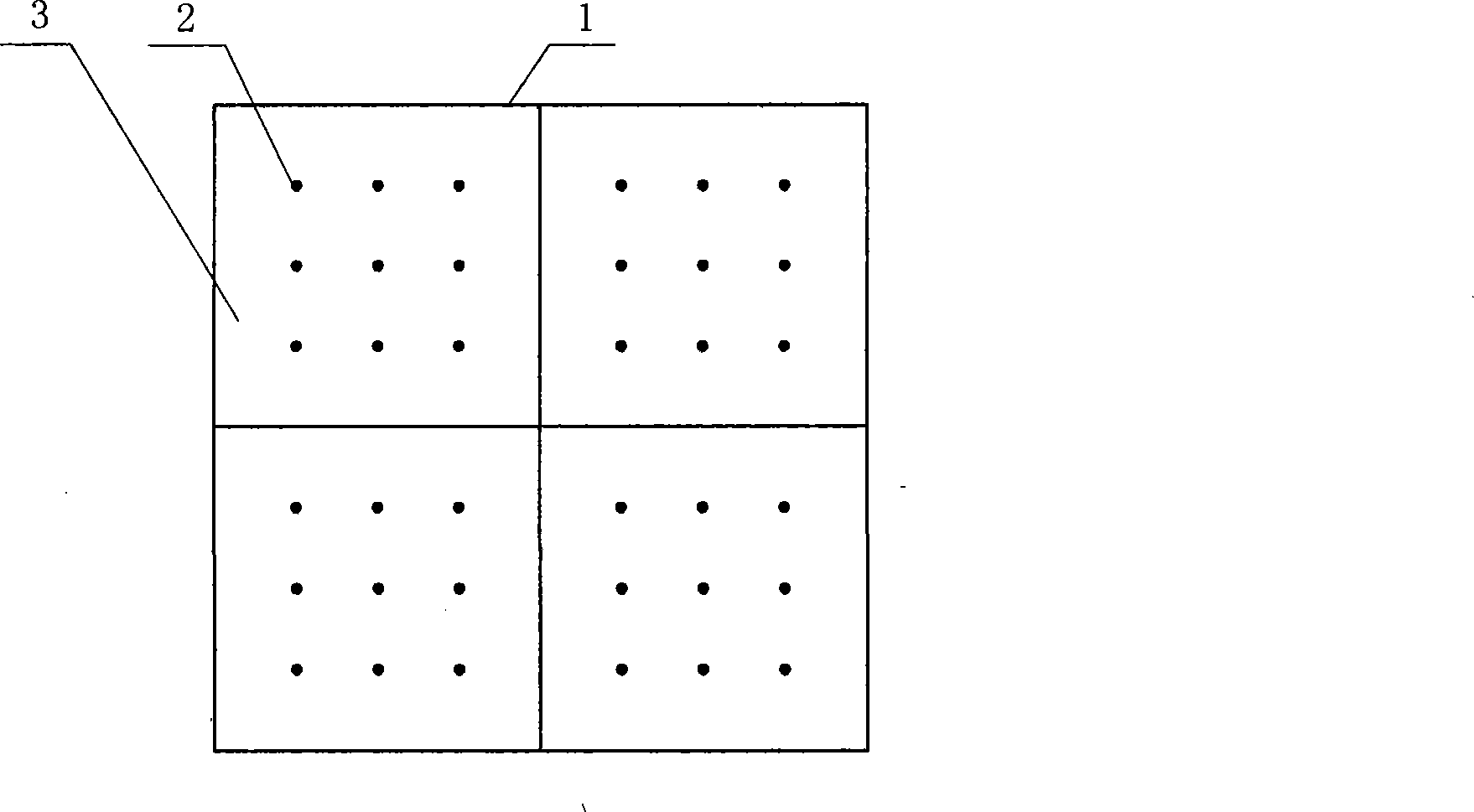

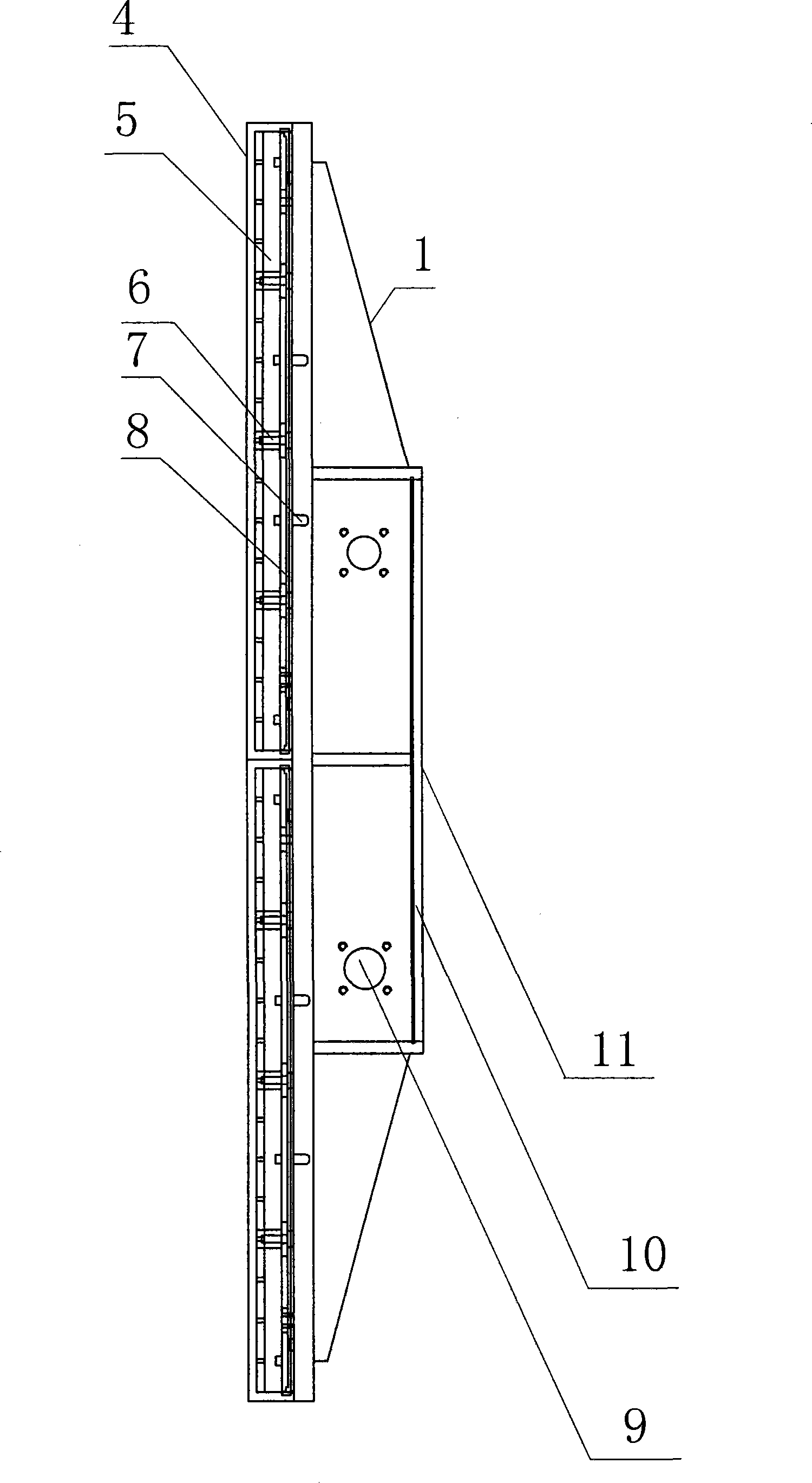

[0023] The improved technical scheme of the LED display floor structure described in this embodiment, such as figure 1 , image 3 As shown, it is composed of four cubes 3 with the same structure installed in the bottom frame 1 , each cube 3 is formed by fastening a mask 4 and a bottom shell 5 , and the fixed module 2 is installed in the cube 3 .

[0024] The face shield 4 and the bottom shell 5 are screwed together with screws passing through the internal threaded holes 6 of the bottom shell.

[0025] Each of the cubes 3 is mounted on the corresponding position of the bottom frame 1 through the positioning column 7 on the bottom case 5 .

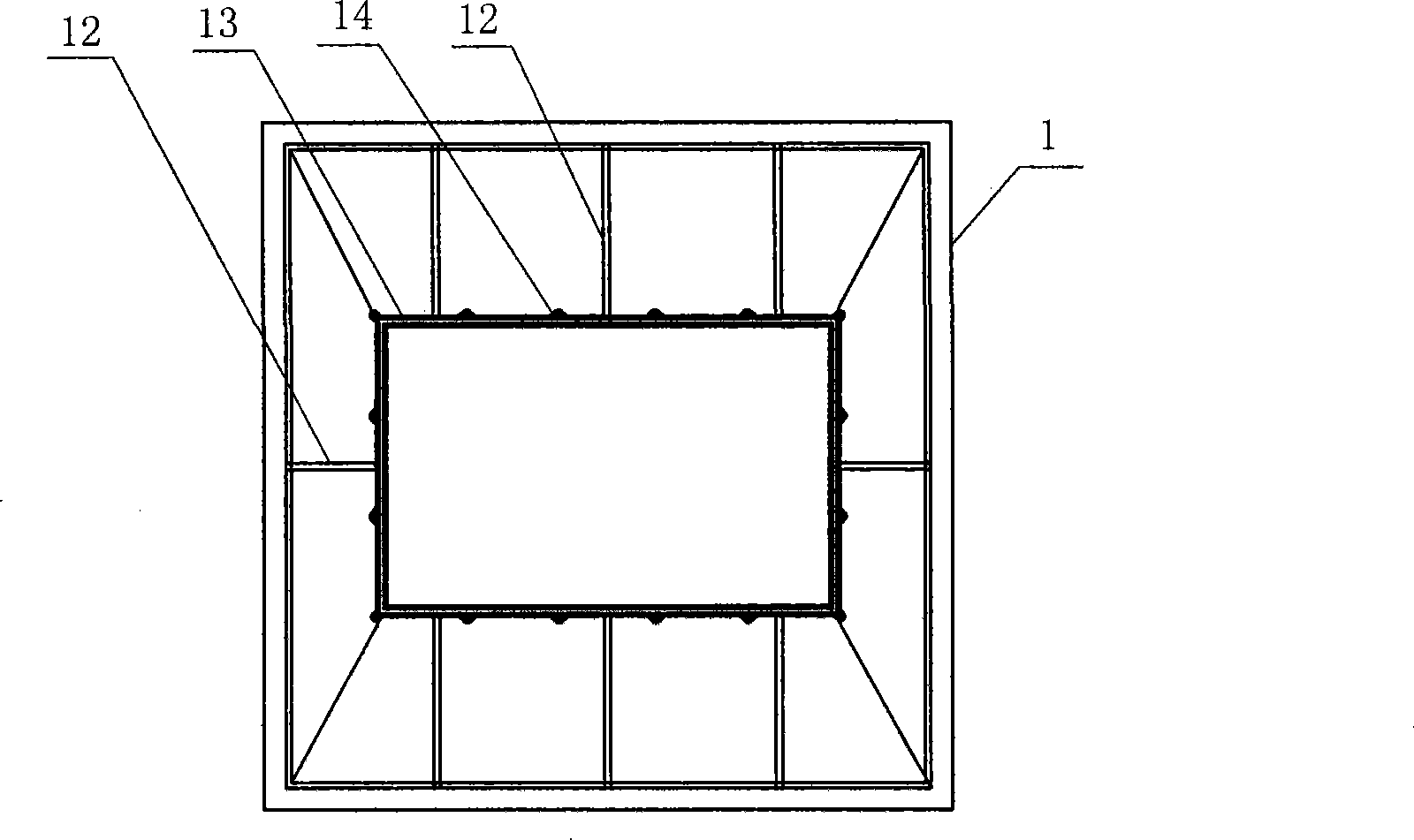

[0026] Such as figure 2 As shown, the lower part of the bottom frame 1 is trapezoidal, and the four sides of the upper bottom of the trapezoid are provided with waterproof grooves 13, and waterproof rubber strips 10 are arranged in the waterproof groove 13; The waterproof cover plate 11 is screwed; the trapezoidal lower bottom of the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com