Foam generator for coal mine dedusting

A foam generating device and coal mine technology, applied in safety devices, dust prevention, mining equipment, etc., can solve the problems of different film forming efficiency, reduce the foaming ratio, and affect the foaming effect, etc., achieve compact structure, improve foaming Good effect and foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

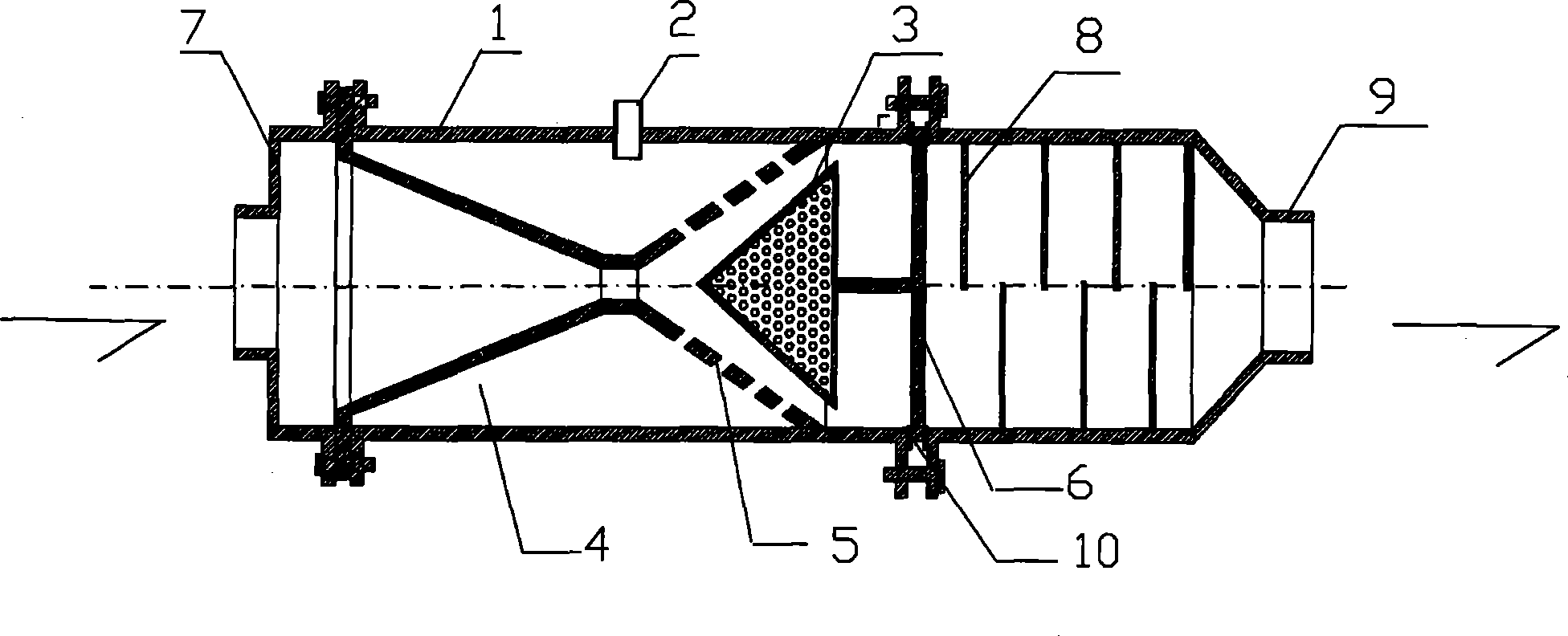

[0011] As shown in the accompanying drawings, the entire foaming cylinder is composed of a Venturi tube 1, a foam barrier tube 9 and a tailpiece 7. The foam barrier tube 9 is connected to the front end of the Venturi tube 1 through a flange, and the tailpiece 7 is passed through. The blue is connected to the rear end of the Venturi tube 1. On the surface of the passage diffuser section of Venturi tube 4, several air inlet holes 5 are evenly distributed, and a spoiler 3 of a hollow cone is fixed in the diffuser section of Venturi tube 4, and the conical surface of spoiler 3 and Venturi tube Corresponding to the diffusion section of the inner tube 4, it is placed in the expansion section of the Venturi tube 4 lying down. It is fixed at the joint between the Venturi tube 1 and the foam barrier tube 9 through the fixing bracket 6, the joint is equipped with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com