Cold type thruster

A propeller, cold technology, applied in thrust reversers, machines/engines, mechanical equipment, etc., can solve the problems of high requirements on jet engine materials, increase in jet engine cost, and high jet engine temperature, and achieve cost Low cost, simple structure and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

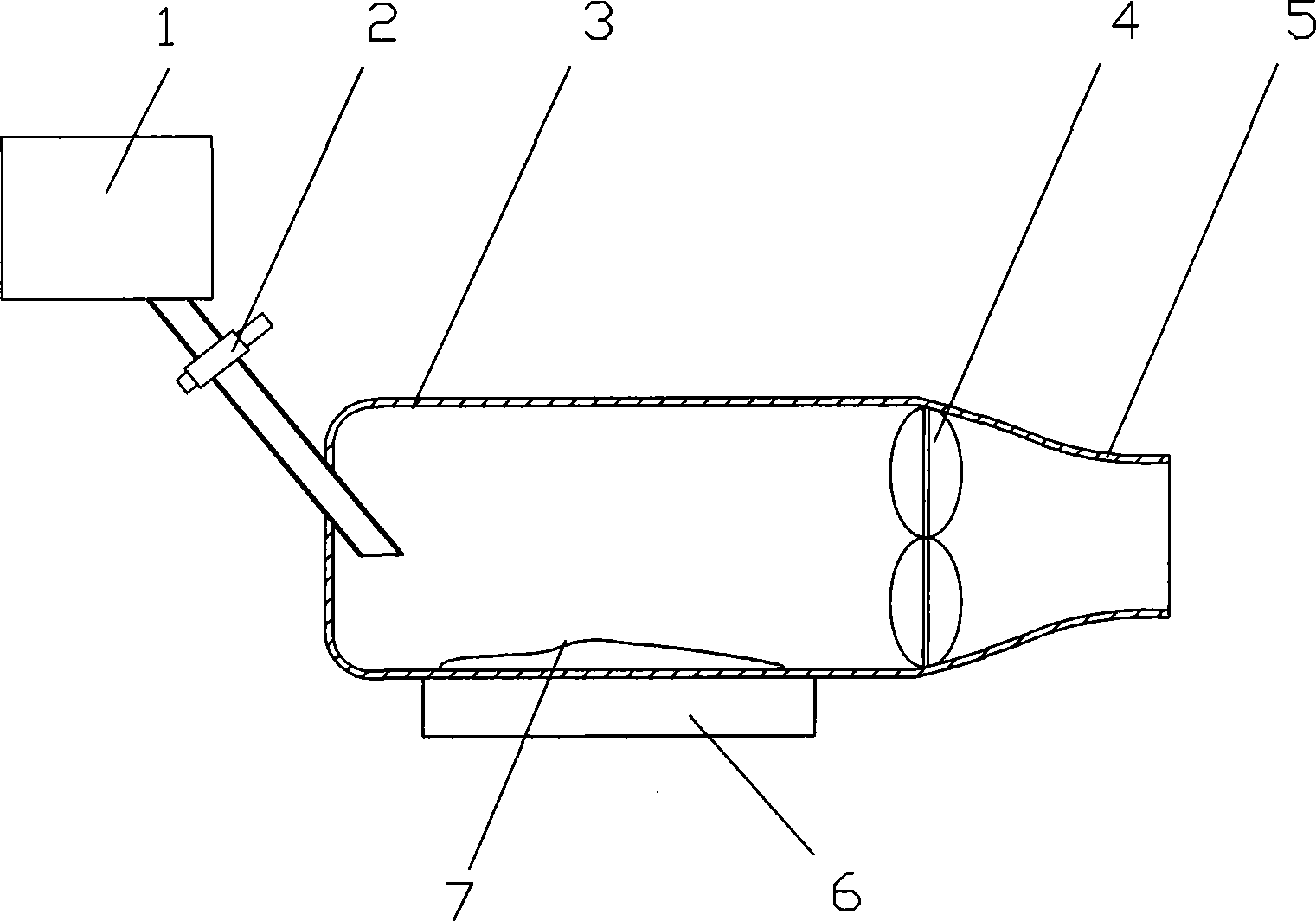

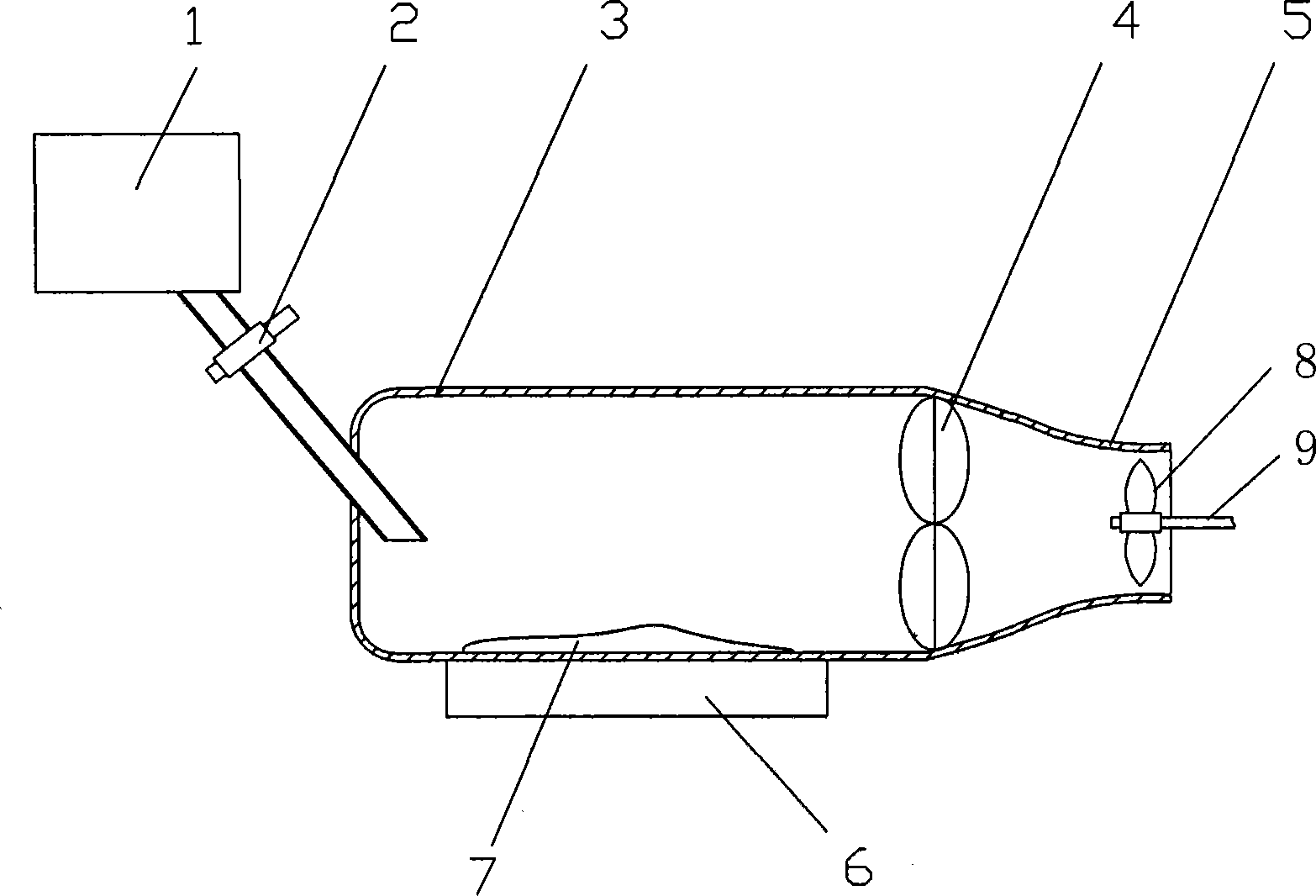

[0014] see figure 1 , the vaporization chamber 3 is provided with a nozzle 5, a pressure switch 4 is provided at the position corresponding to the nozzle 5 in the vaporization chamber 3, a liquefied gas heating device 6 is provided at the bottom of the vaporization chamber 3, and a vertical wheel feeder is provided in the vaporization chamber 3. The ice device 1 is provided with a one-way feeding valve 2 on the vertical wheel ice delivery device 1 .

[0015] Referring to the accompanying drawings, the vertical wheel ice delivery device 1 adds dry ice 7 into the vaporization chamber 3, and the liquefied gas heating device 6 heats the dry ice 7. The dry ice 7 is vaporized after heating, and its volume expands 700-800 times after vaporization. A very high pressure is generated in the vaporization chamber 3, and when the pressure reaches a certain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com