Gas flow regulating valve

A gas flow and regulating valve technology, which is applied in the direction of valve lift, valve detail, safety valve, etc., can solve the problems of small movement stroke, wear and elastic decline of shrapnel, and achieve fast dynamic response, high adjustment precision and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

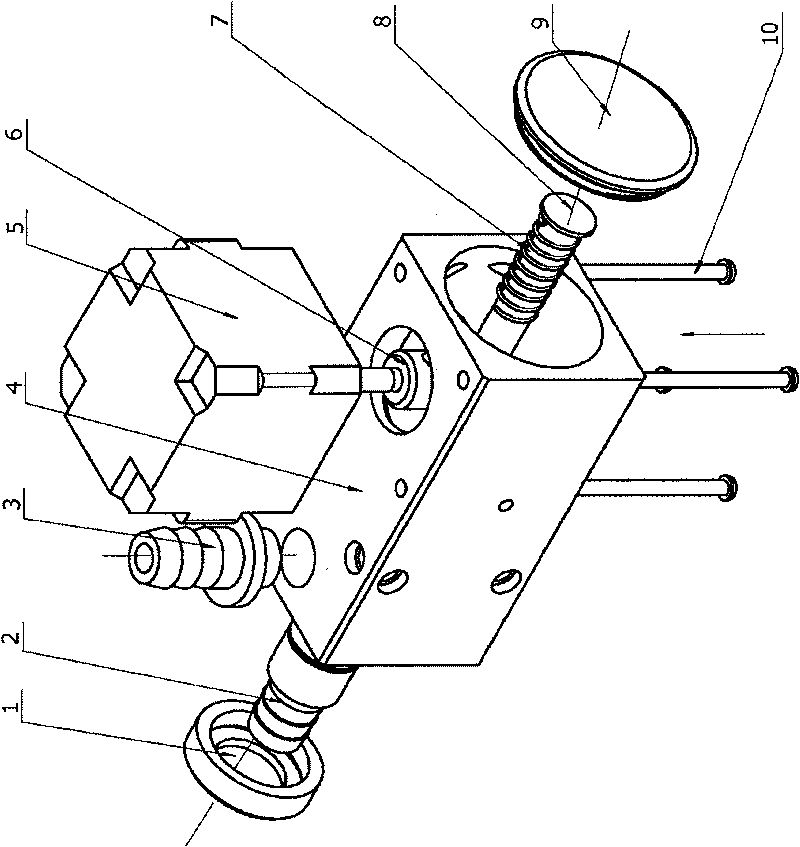

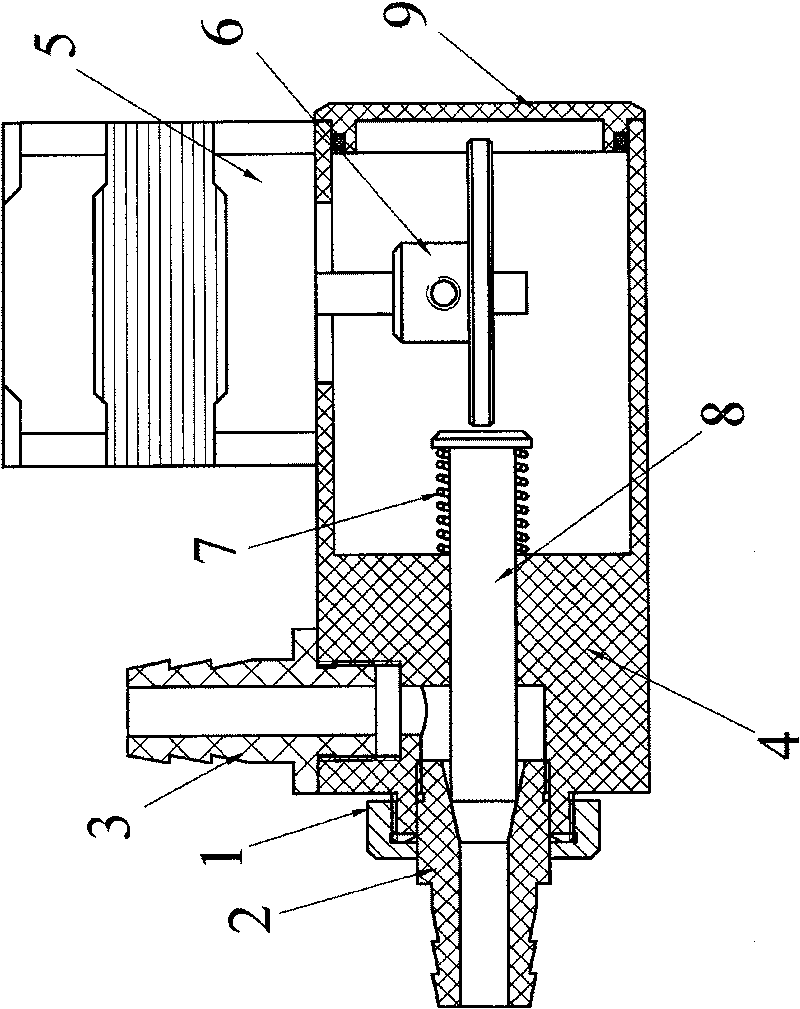

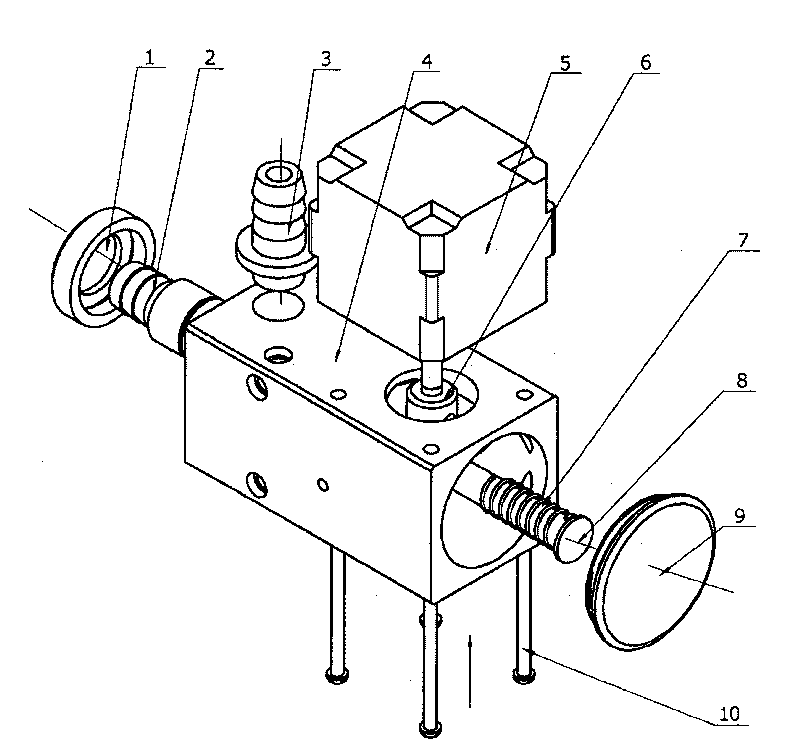

[0022] see figure 1 As shown, it is a three-dimensional exploded view of the gas flow regulating valve of the present invention; it includes a regulating valve main body 4, on which an air inlet nozzle 2 and an air outlet nozzle 3 are arranged. The valve main body 4 can be integrally formed (the present invention does not go into details on this, it is achievable for those skilled in the art by casting or welding), and it can also be independent from the regulating valve main body 4; a spool rod 8, which is arranged in the main body 4 of the regulating valve, and the main body 4 of the regulating valve is sealed by a gland 9; The tightness of the air inlet nozzle controls the effective diameter of the shut-off port, thereby controlling the amount of gas entering from the air inlet nozzle 2 and finally con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com