Dielectric elastomer folding-shaped driver making method

A technology of a dielectric elastomer and a manufacturing method, which is applied in the directions of generators/motors, electrostatic generators/motors, electrical components, etc., can solve the problems of long response time, complex structure, and high noise.

Inactive Publication Date: 2010-11-10

HARBIN INST OF TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to solve the problems of existing mechanical drive, hydraulic drive and motor drive, which require long response time, produce large noise, large volume, large weight, large power consumption, complex structure, poor flexibility and poor biocompatibility. problem, provide a method of manufacturing a dielectric elastomer folded driver

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

specific Embodiment approach 2

specific Embodiment approach 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

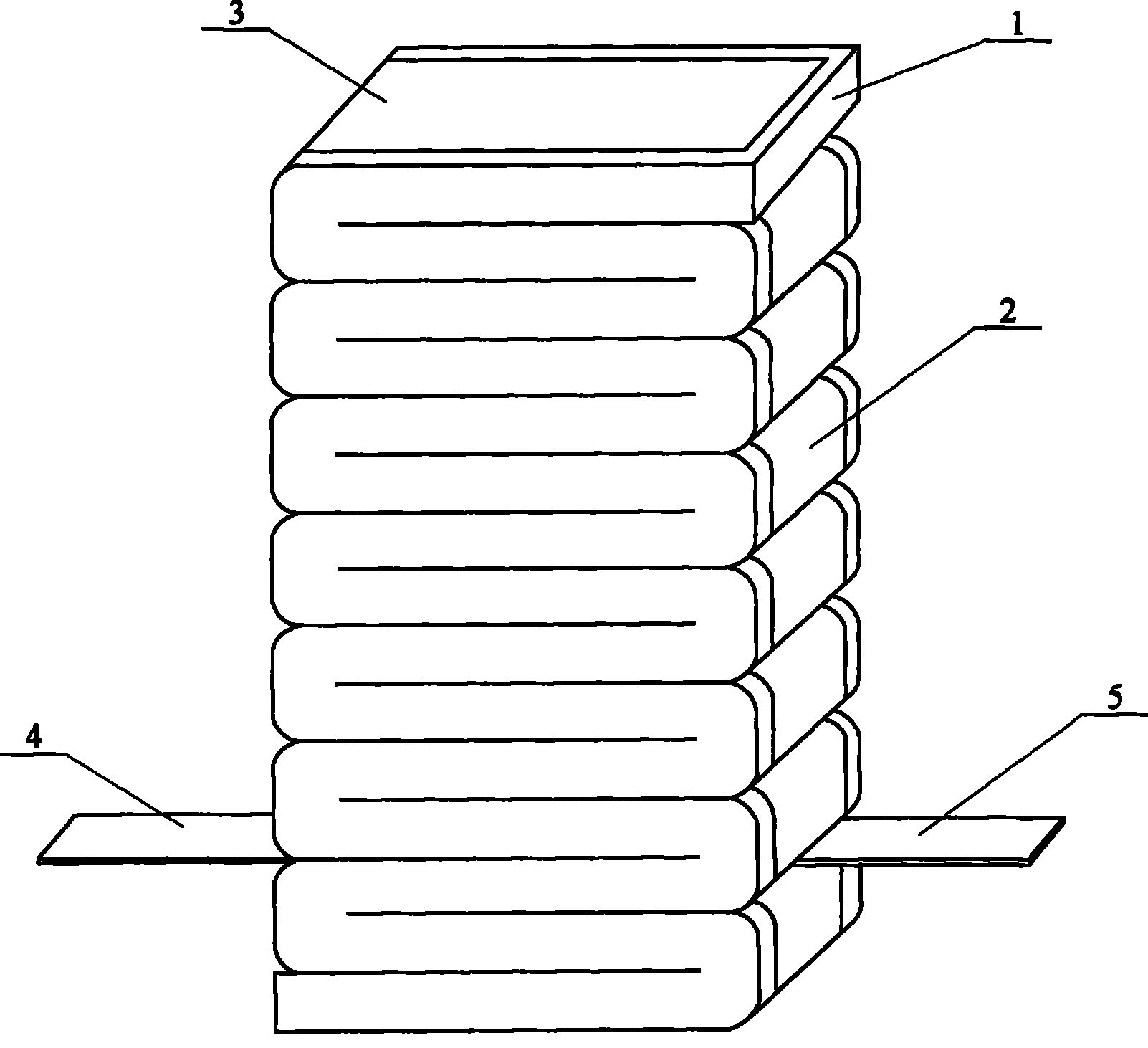

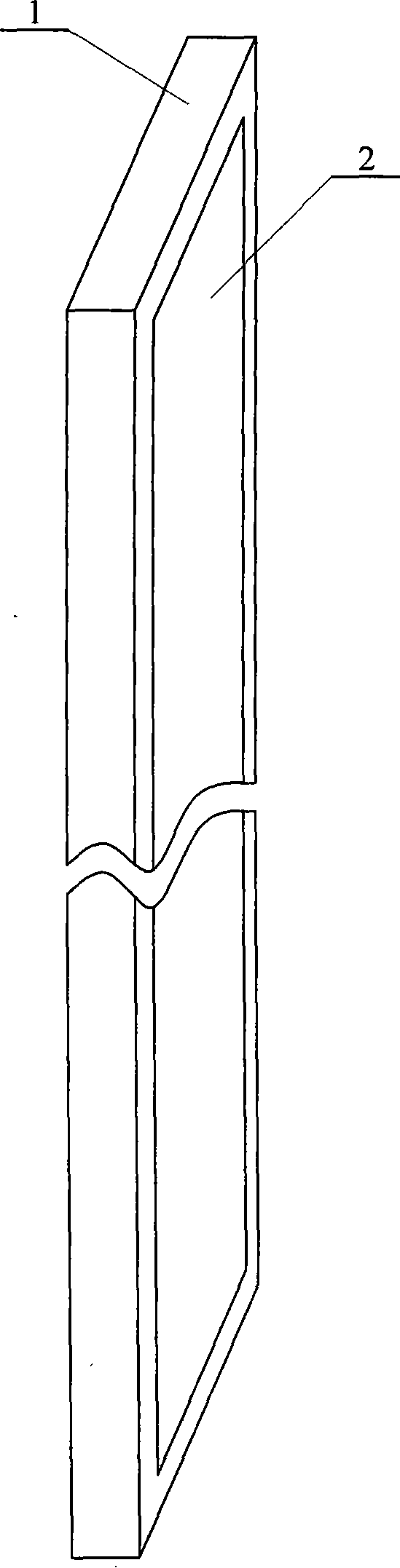

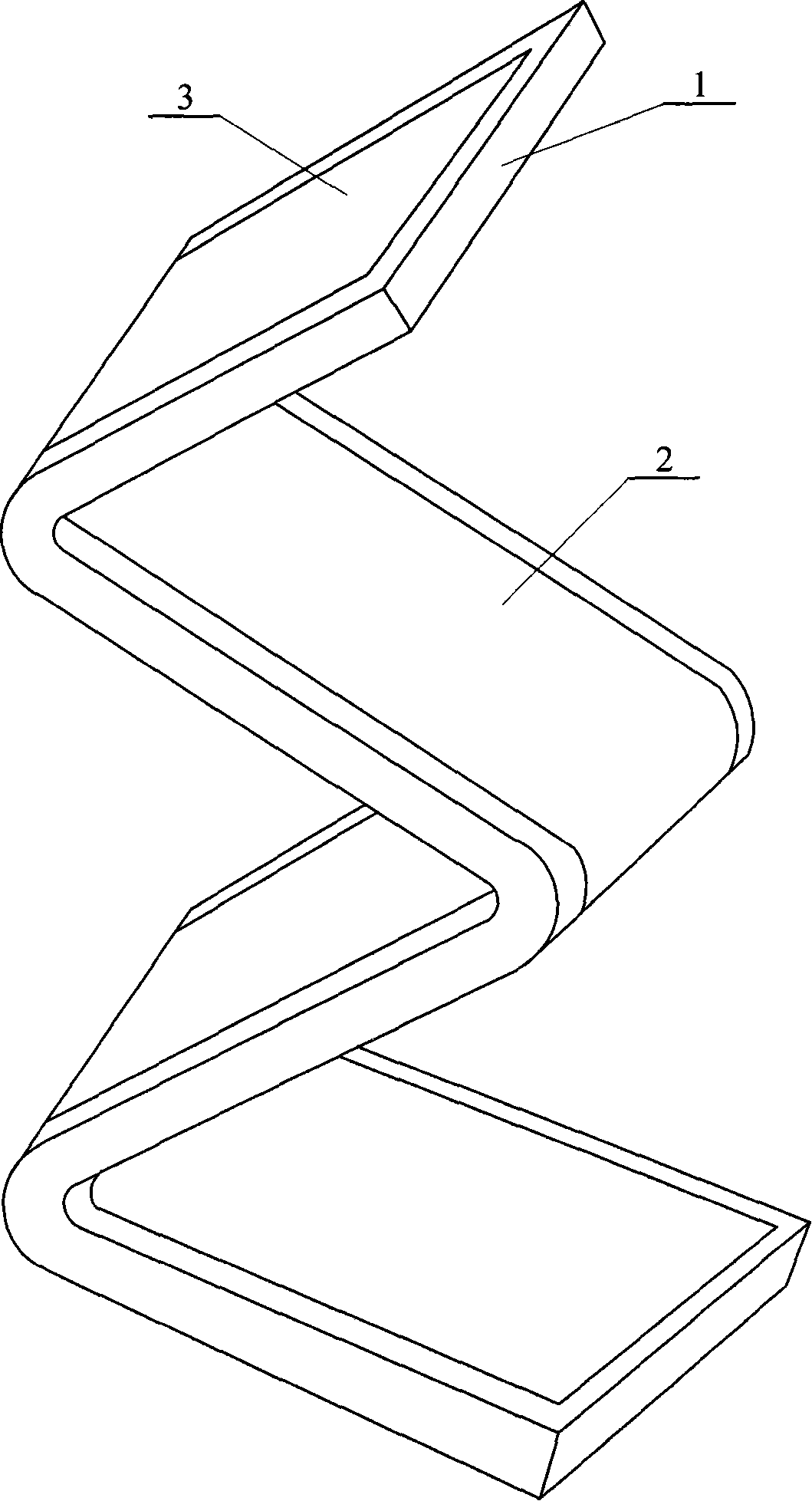

A folded dielectric elastomer driver and the manufacturing method thereof are disclosed, relating to a driver and the manufacturing method thereof. The invention aims at solving the problems of long response time, big noise, large size, big weight, great electricity consumption and poor flexibility in current mechanical driving, hydraulic driving and motor driving modes. The invention sequentially folds a dielectric elastomer film which is provided with a first flexible electrode and a second flexible electrode into a cuboid body. The method is that 7-15 potions of silastic virgin rubber, 0.3-1.6 potions of activator and more than 0-5.5 potions of elasticity modulus regulation agent are mixed round with a stirring mill with a rotating speed of 40-400r / m under room temperature for 3-5 minutes and then are solidified for 16-48 hours. The driver of the invention is of big transfiguration, high elastic energy density, short response time, long fatigue lifetime, small volume, high precision, little noise, good flexibility and good simulation property. The method is simple in technique and short in technological process and the products made with the method are of reliable quality.

Description

Fabrication method of dielectric elastomer folded actuator technical field The invention relates to a manufacturing method of a driver. Background technique As far as the driver is concerned, the existing mechanical drives, hydraulic drives, and motor drives have the problems of long response time, large noise, large volume, heavy weight, high power consumption, complex structure, poor flexibility, and poor biocompatibility. Contents of the invention The purpose of the present invention is to solve the problems of existing mechanical drive, hydraulic drive and motor drive, which require long response time, produce large noise, large volume, large weight, large power consumption, complex structure, poor flexibility and poor biocompatibility. To solve the problem, provide a method for fabricating a dielectric elastomer folded actuator. The dielectric elastomer folded driver of the present invention is composed of a dielectric elastomer film, a first flexible electrode, a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H02N1/00

Inventor 冷劲松刘彦菊张震刘立武施亮邓刚

Owner HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com