Steel rail roller conveyer

A technology of conveyors and rollers, which is applied in the direction of rollers, mechanical equipment, transportation and packaging, etc., can solve the problems of complex structure, large volume, removal, etc., and achieve the effect of compact structure, small volume and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

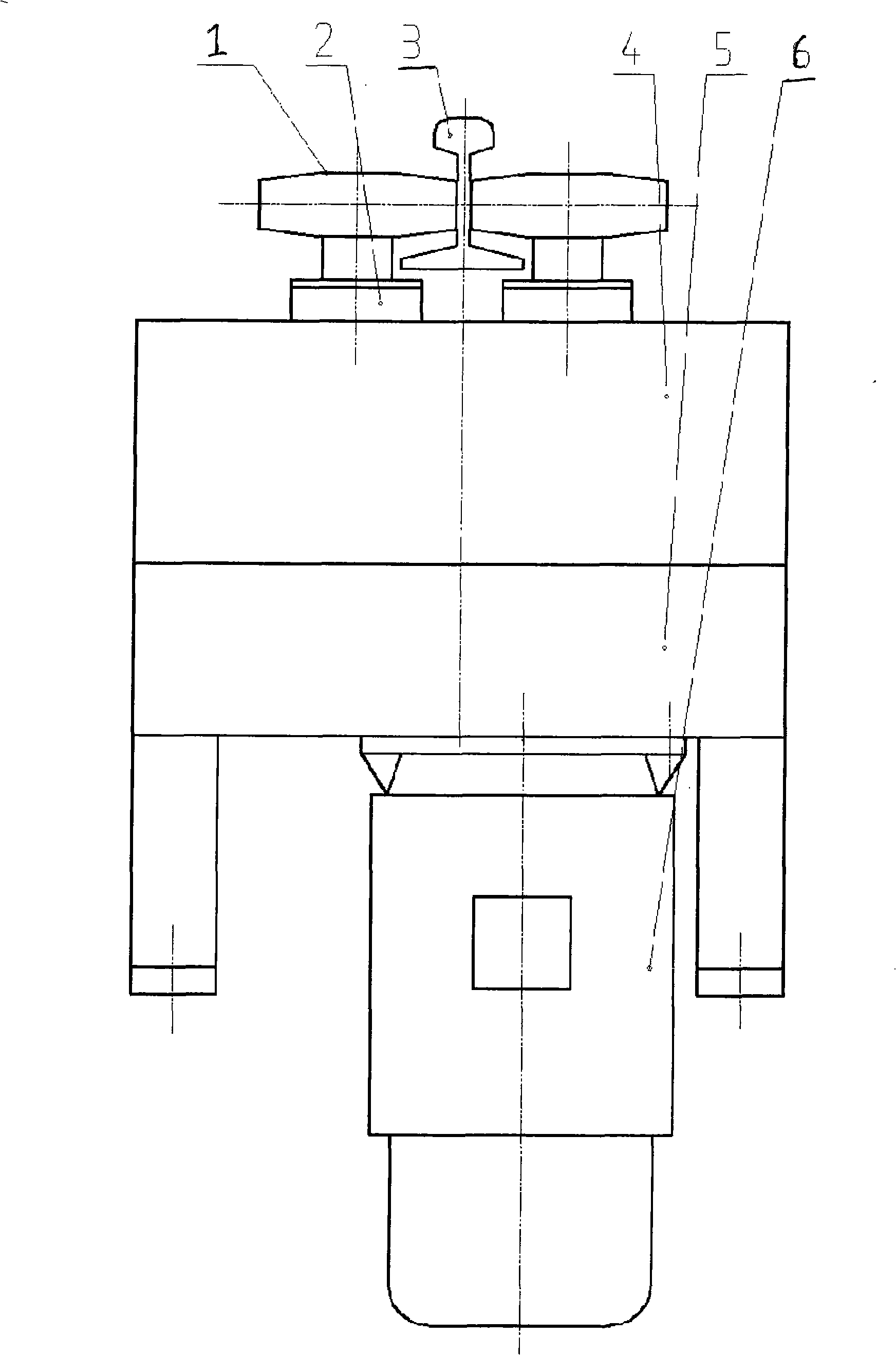

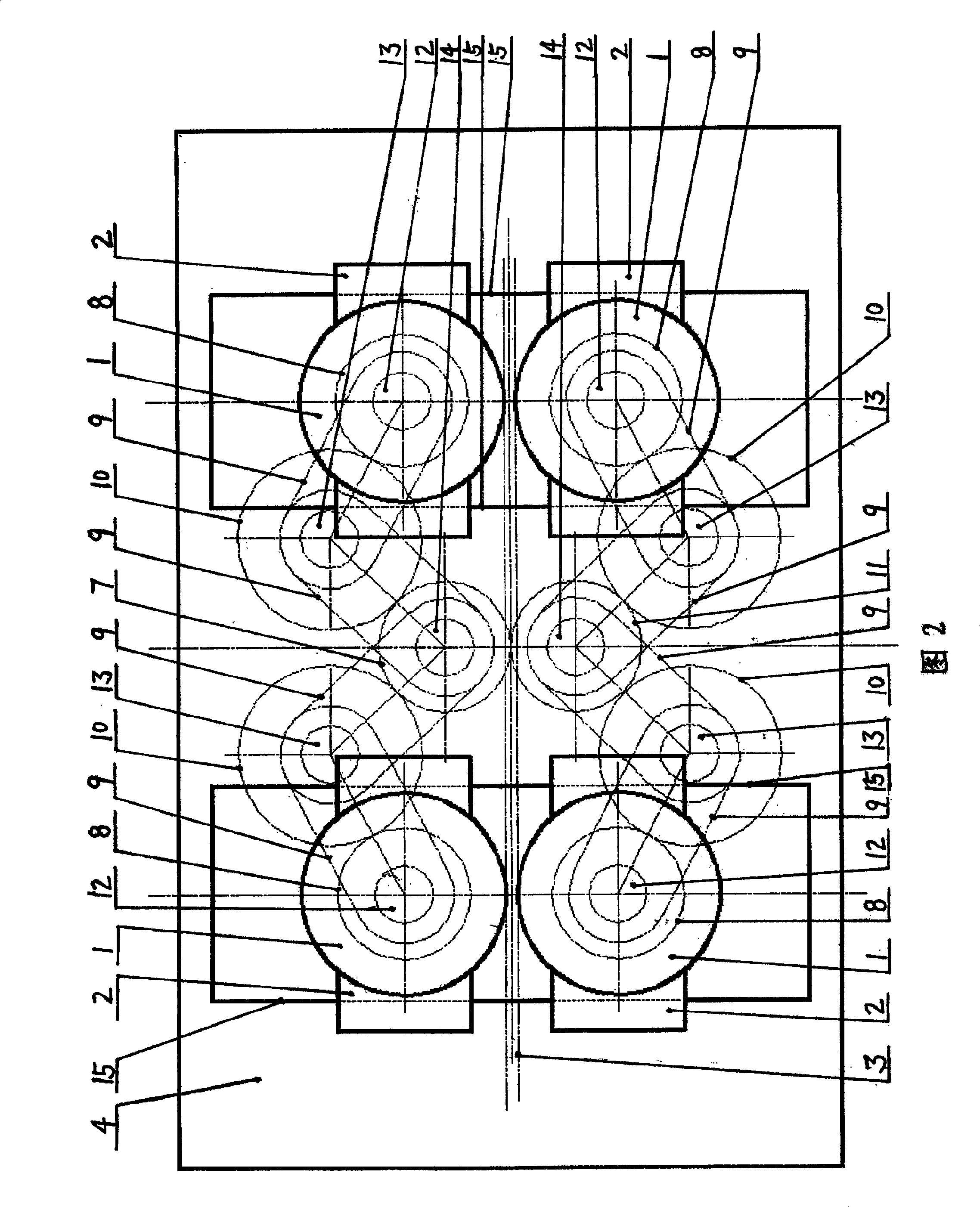

[0008] Below in conjunction with accompanying drawing, the present invention will be further described: figure 1 , shown in Fig. 2, two pairs of driving vertical rollers 1 clamp the rail waist 3, and the motor 6 transmits power to the opening and closing driving vertical roller box 4 through the reduction box 5. As shown in Figure 2, in the opening and closing driving vertical roller box 4, the gears 7, 8, 10, 11 are meshed with each other, and the intermediate gear shaft 13 is respectively connected with the rotating arm 9 on the driving vertical roller main shaft 12 and the fixed transmission shaft 14. Rotary arm 9 is hinged. Each driving vertical roller main shaft 12 forms a gear-link mechanism with the fixed transmission shaft 14 respectively, and four driving vertical roller main shaft boxes 2 are independent casings and have a closed guide rail structure. Gears 7 and 11 are fixed in position. Due to the principle of the gear-link mechanism, the driving vertical roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com