Paper winder and working method thereof

A paper winding machine and rolling paper technology, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems affecting the normal production of the paper machine and the increase of the speed of the machine, affecting the time of changing rolls, and affecting the safety of the paper tail and other issues, to achieve the effect of ensuring the quality of high-speed paper, ensuring safe work, and ensuring the speed of the vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

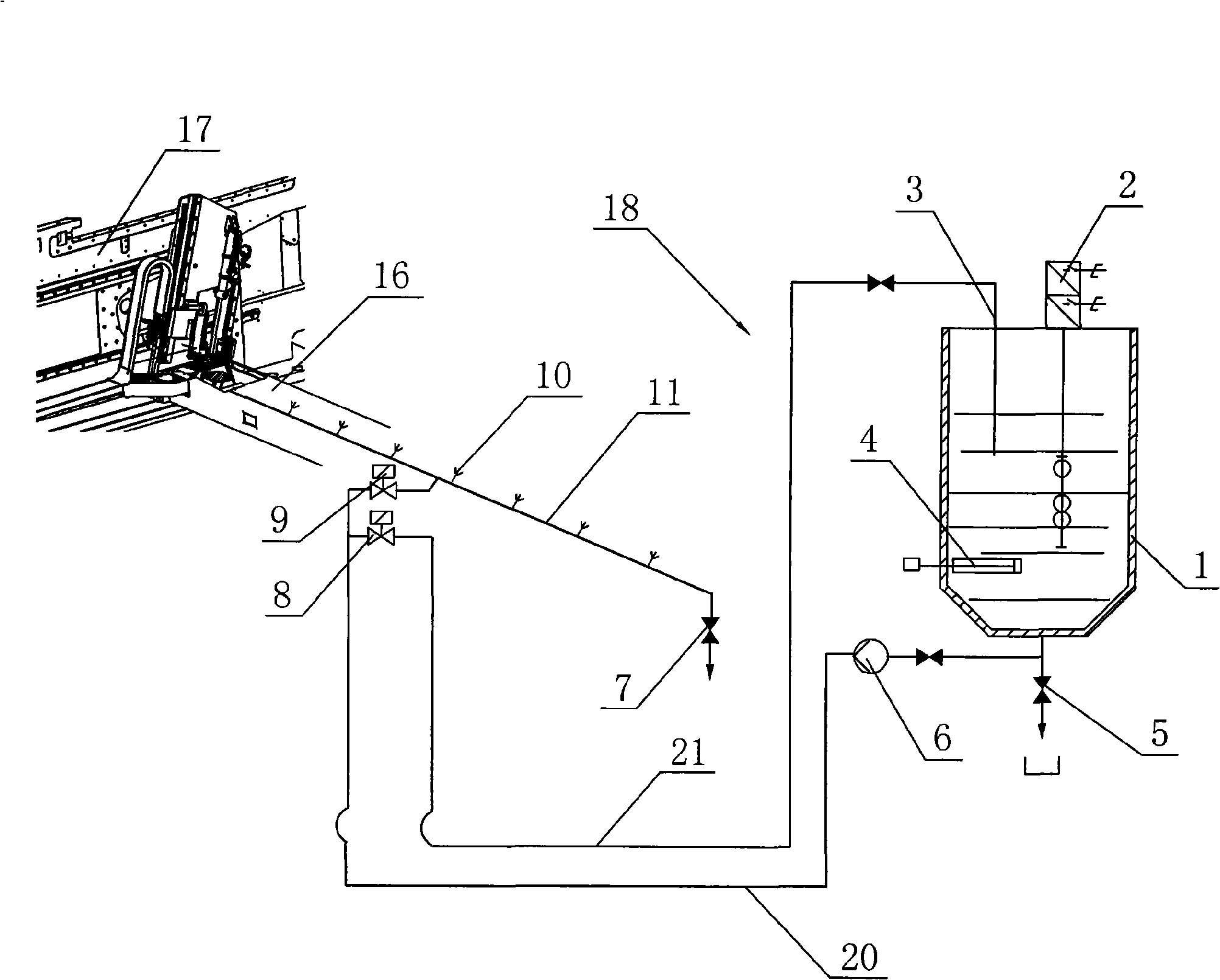

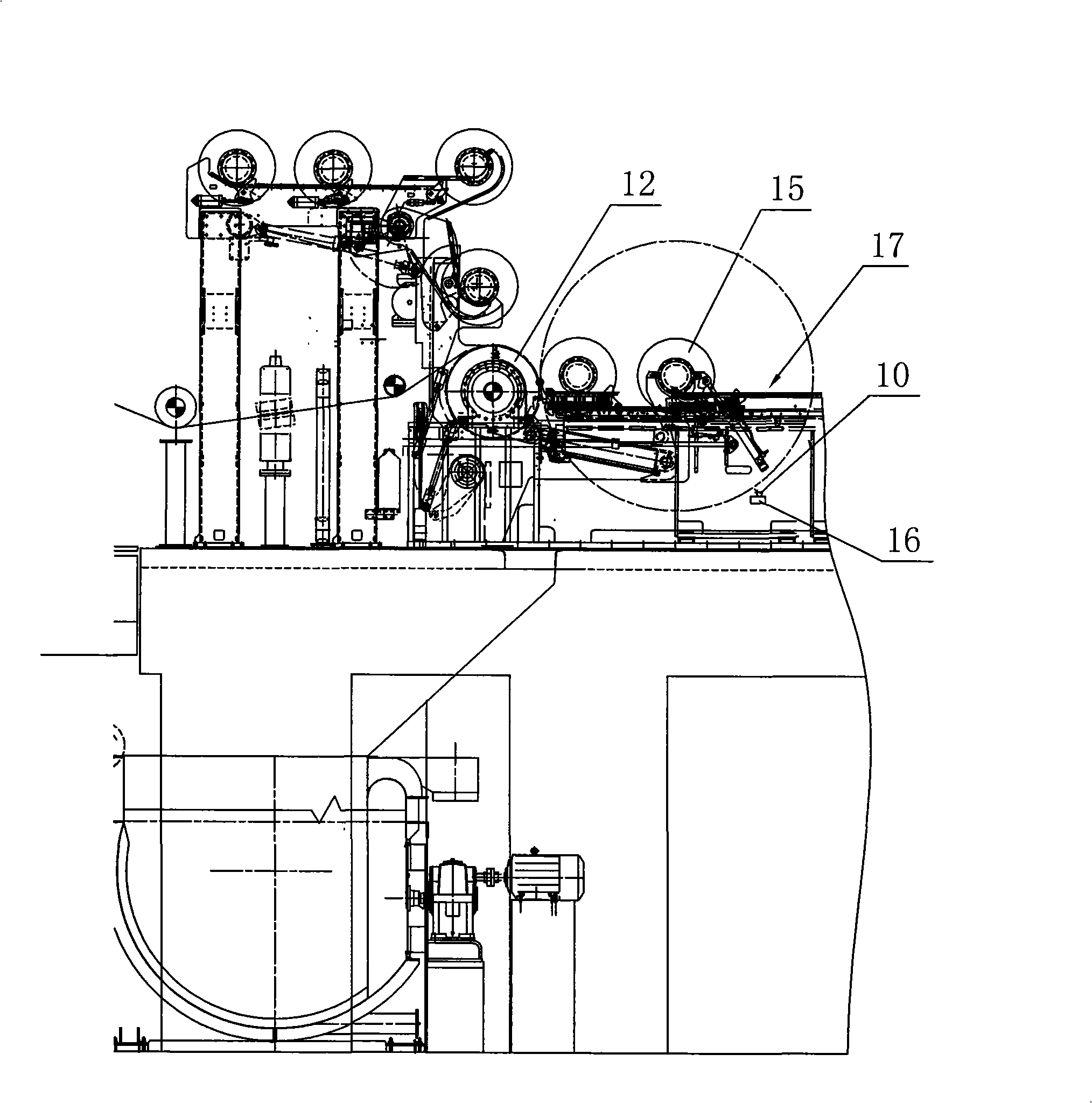

[0022] As shown in the figure, a paper reel includes a workbench 17 on which a reel cylinder 12, a roll change iron core 15 and a loading brake device 16 are arranged. The glue spraying system 18 whose end is bonded to the surface of the paper roll, the glue spraying system 18 includes a glue bucket 1 for holding the glue, a glue spray valve 9, an automatic backflow valve 8 and a plurality of nozzles connected with each other by pipes 11 10. The pipeline 11 is fixedly installed on the loading brake device 16, the pipeline 11 is provided with a cleaning valve 7, the bottom of the rubber barrel 1 is provided with a discharge pipe 20, and a pump 6 is provided on the discharge pipe 20, and the pump 6 passes through the glue spray The valve 9 is connected with the nozzle 10, the pump 6 is connected with the return automatic valve 8 at the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com