Method and apparatus for controlling central air-conditioning end supply backwater temperature difference

A technology of temperature difference between supply and return water and central air-conditioning, applied in space heating and ventilation, heating and ventilation control systems, household heating, etc. Too big and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

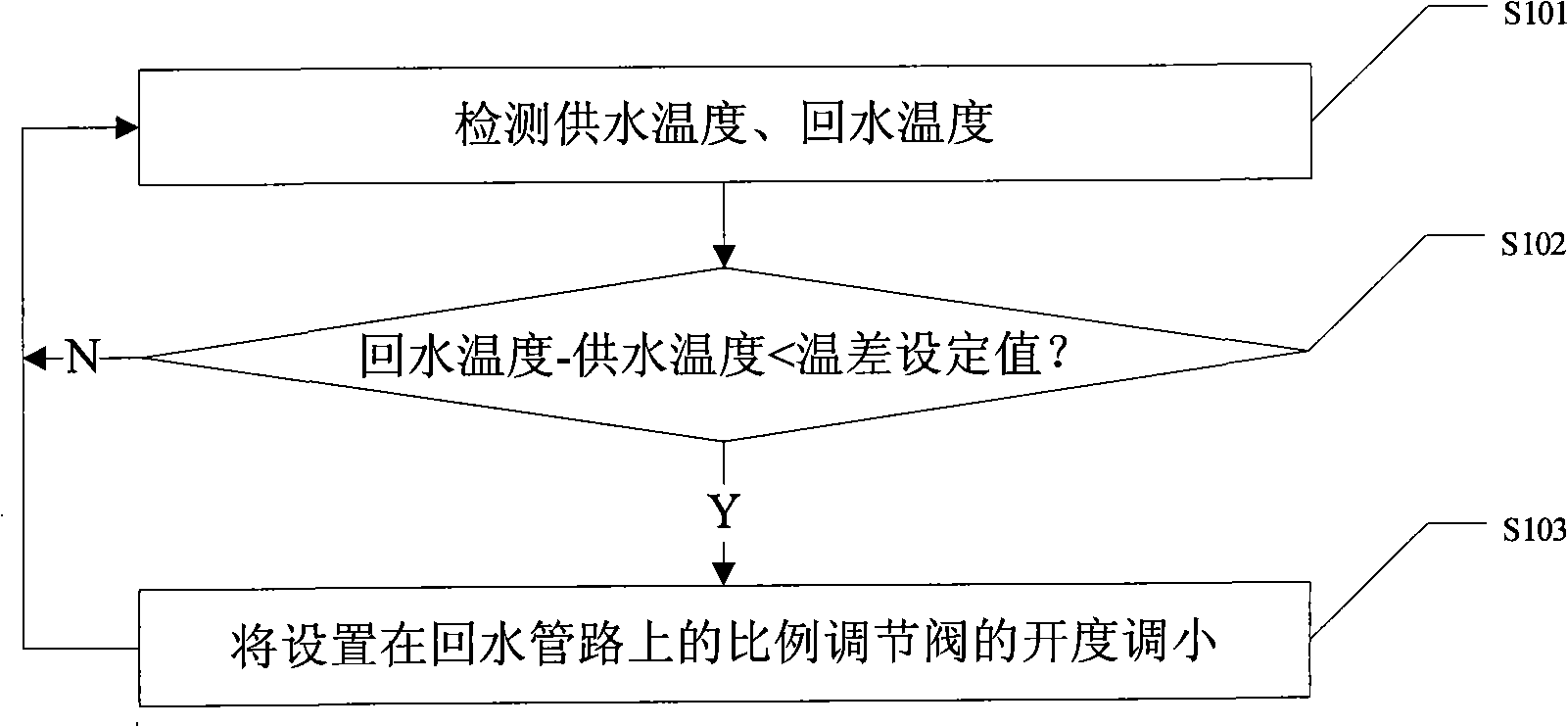

[0035] Such as figure 1 Shown is a schematic flow chart of Embodiment 1 of the method for controlling the temperature difference between supply and return water at the terminal of a central air conditioner in the present invention. In this embodiment, the terminal equipment of the central air conditioner has already met the requirement of the set value of the room temperature.

[0036] Such as figure 1 Shown, in the present embodiment, method of the present invention comprises steps:

[0037] Step S101: Detect the supply water temperature in the water supply pipeline and the return water temperature in the return water pipeline, and proceed to step S102;

[0038] Step S102: Determine whether the difference between the return water temperature minus the supply water temperature is less than the temperature difference set value, if yes, go to step S103, if not, do not take any action, or return to step S101 to continue detection afterward or after a period of time, According ...

Embodiment 2

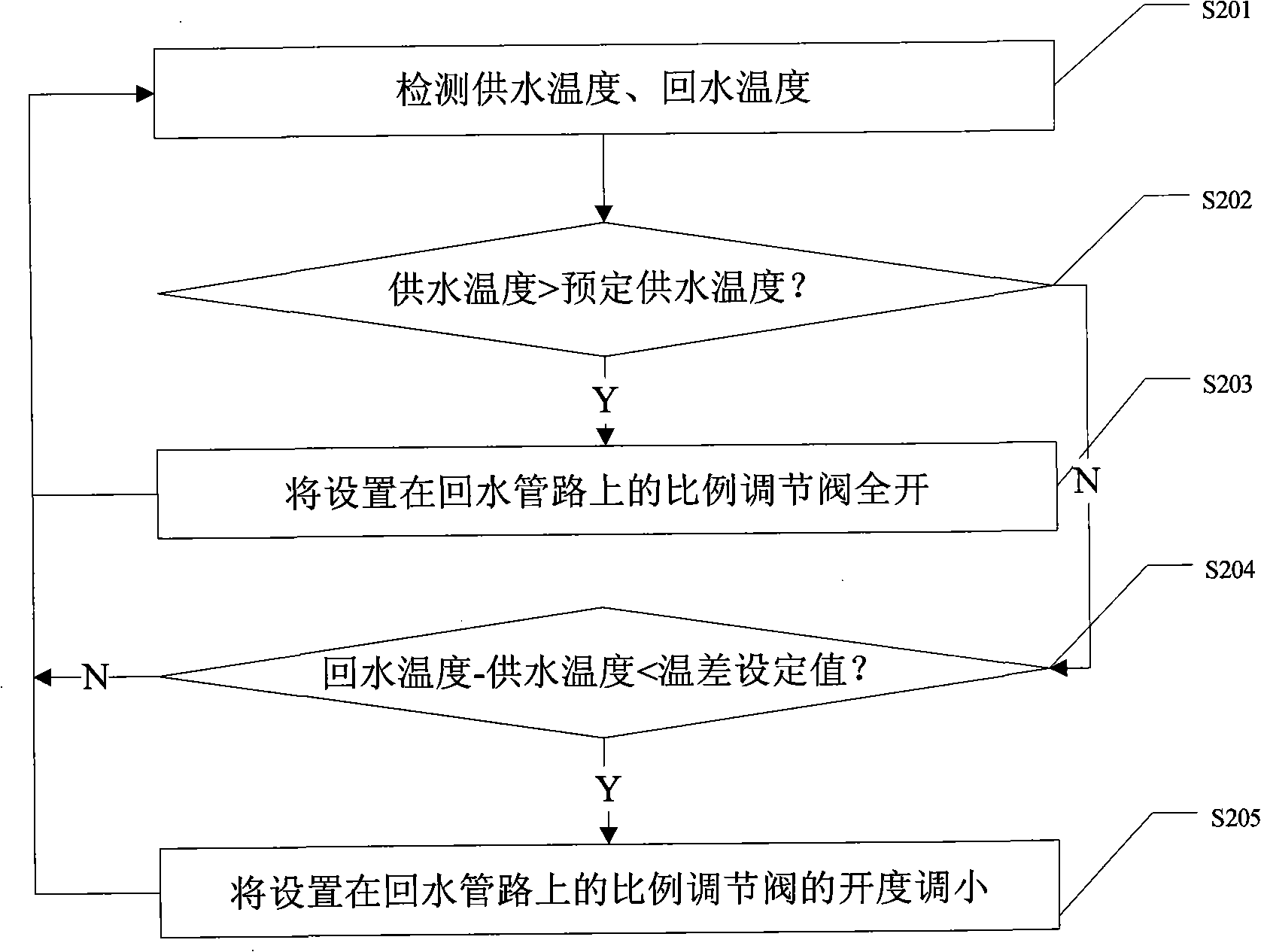

[0044] Such as figure 2Shown is a schematic flow chart of Embodiment 2 of the method for controlling the temperature difference between supply and return water at the terminal of a central air conditioner in the present invention. In this embodiment, the main difference from Embodiment 1 is that in the method of this embodiment, the temperature of the water supply on the water supply pipeline is prioritized for determination.

[0045] Such as figure 2 As shown, in this embodiment, the method in this embodiment includes steps:

[0046] Step S201: Detect the supply water temperature in the water supply pipeline and the return water temperature in the return water pipeline, and proceed to step S202;

[0047] Step S202: Determine whether the water supply temperature is higher than the predetermined water supply temperature, if yes, go to step S203, if not, go to step S204;

[0048] Step S203: Control fully opening the proportional regulating valve set on the return water pipe...

Embodiment 3

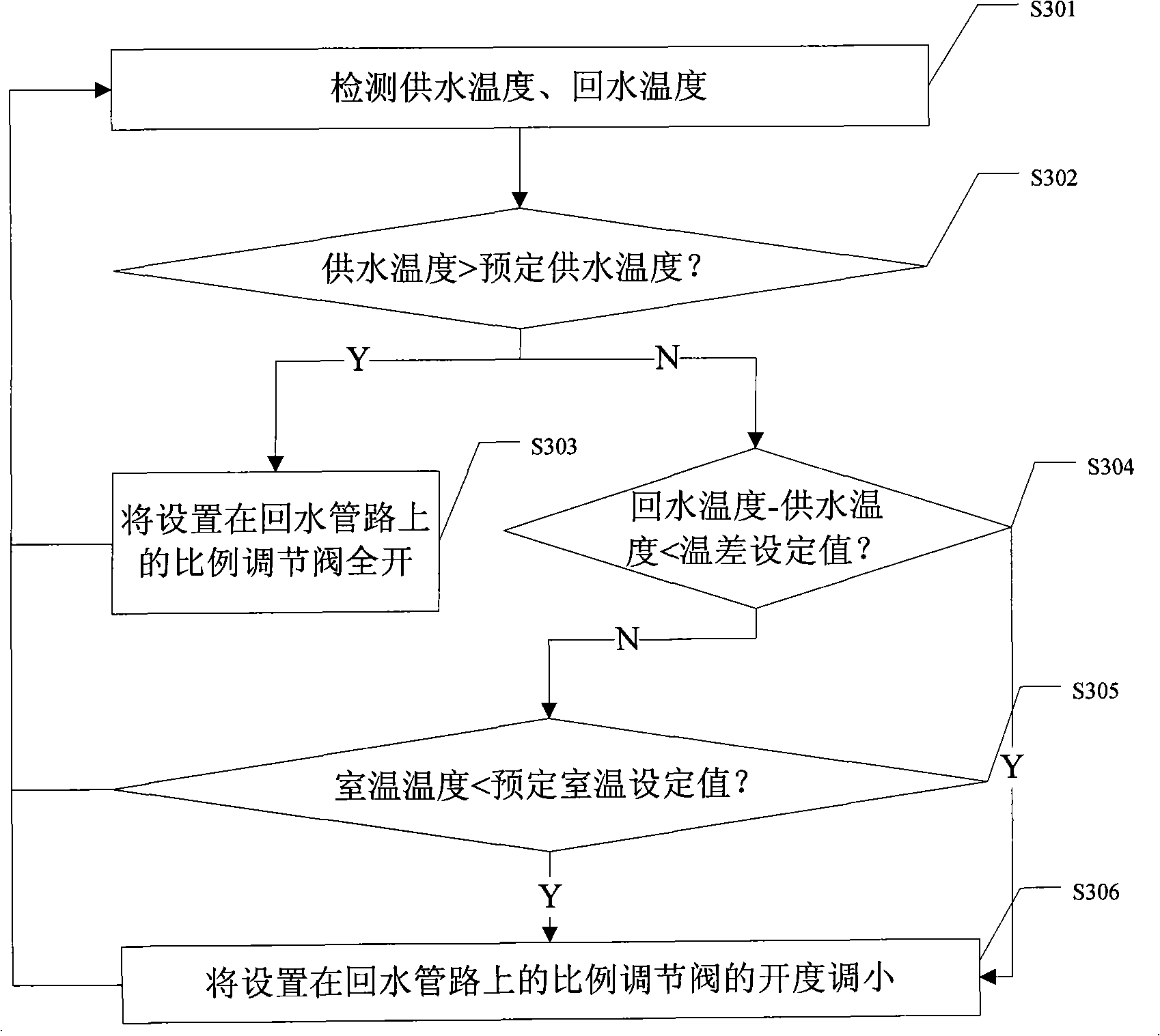

[0055] Such as image 3 As shown, it is a schematic flow chart of the third embodiment of the method for controlling the temperature difference between the supply and return water at the end of the central air conditioner according to the present invention. In this embodiment, the difference from the second embodiment mainly lies in the addition of Steps for judging whether the room temperature meets the predetermined requirements.

[0056] Such as image 3 Shown, in the present embodiment, method of the present invention comprises steps:

[0057] Step S301: Detect the supply water temperature in the water supply pipeline and the return water temperature in the return water pipeline, and proceed to step S302;

[0058] Step S302: Determine whether the water supply temperature is greater than the predetermined water supply temperature, if yes, go to step S303, if not, go to step S304;

[0059] Step S303: Control the full opening of the proportional regulating valve set on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com