Wind turbine with element for sealing two parts that can be rotated in relation to one another

A technology for seals and components, which is applied in the field of components used to seal two components that can be twisted relative to each other, can solve the problems of roughening, destruction, and surface damage of the seals, and achieve the effect of uniform pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

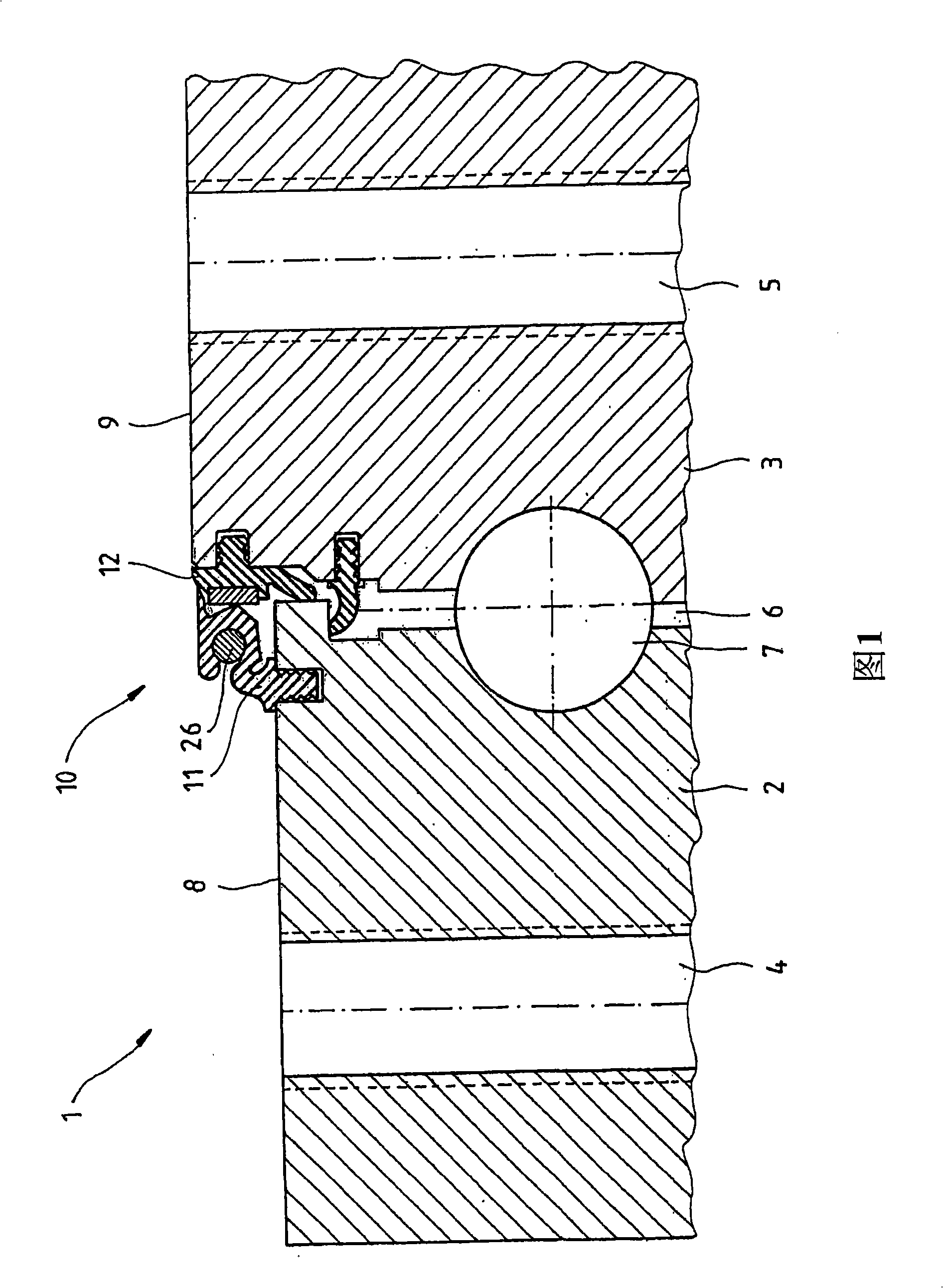

[0044] The ball bearing 1 of FIG. 1 consists of two concentric rings which can be rotated relative to each other. The outer ring 2 can be seen on the left in FIG. 1 and the inner ring 3 can be seen on the right. The two rings 2, 3 are passed through by fixed holes 4, 5 parallel to the axis of rotation. In the region of the gap 6 between the two rings 2 , 3 there is a raceway of at least one row of spherical rolling bodies 7 which allow the relative torsion of the two rings 2 , 3 as a single degree of freedom of movement. On the ball bearing 1, the upper end faces 8, 9 in FIG. 1 are exposed to the open air. For this reason, the gap 6 between the two end faces 8 , 9 is sealed with the seal 10 according to the invention.

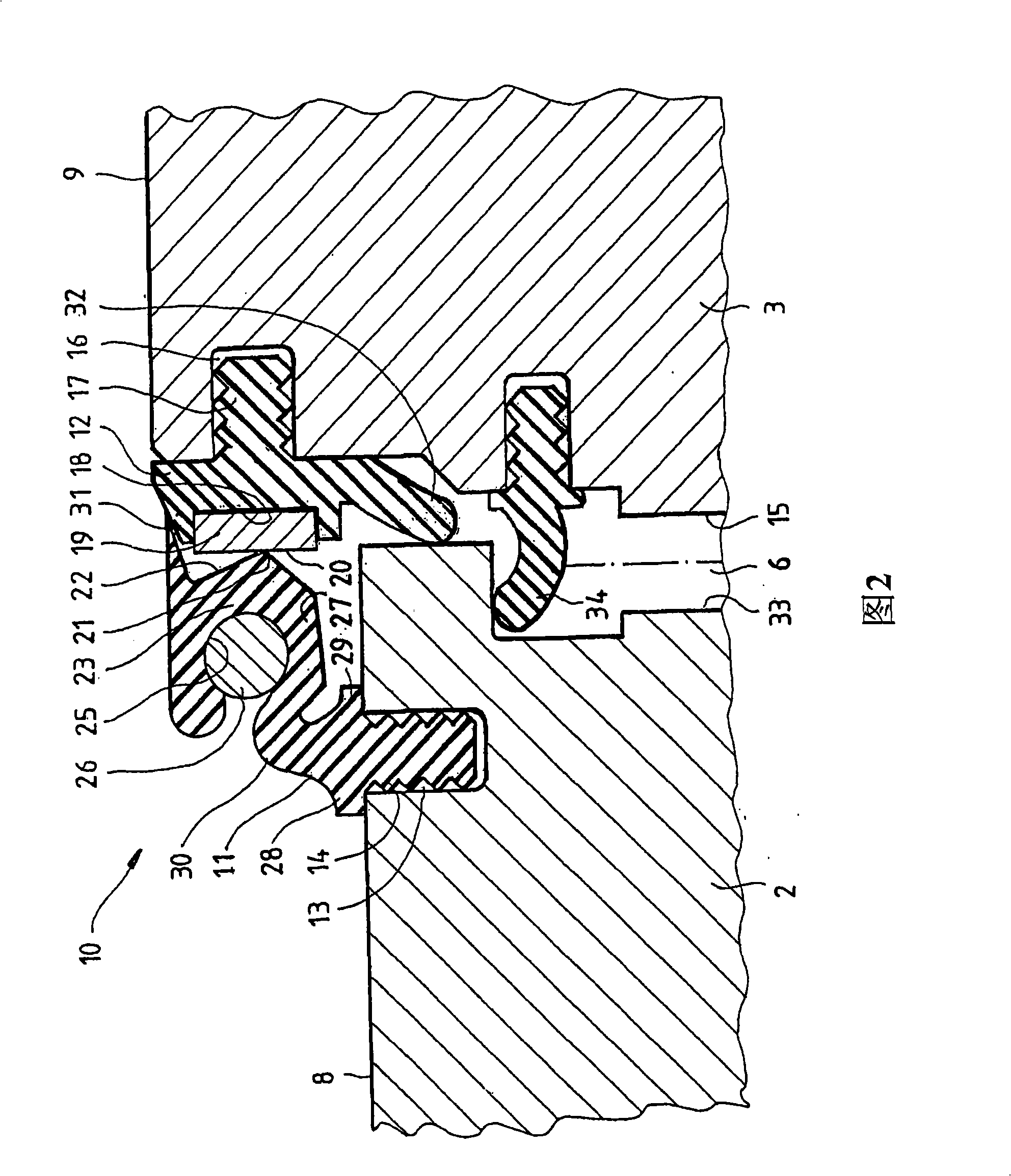

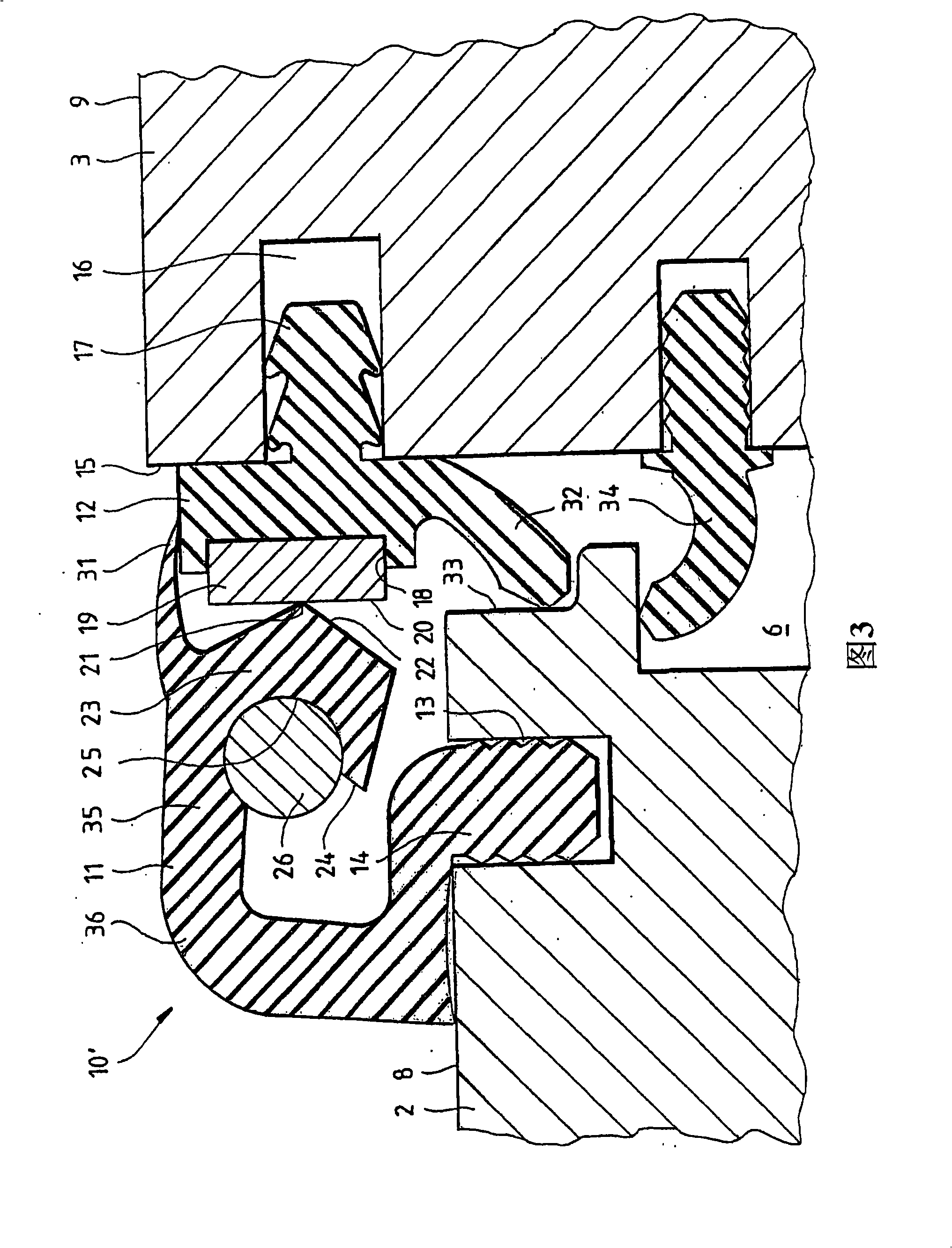

[0045] As shown in FIG. 2 , the sealing member 10 consists of a first sealing ring 11 and a second sealing ring 12 , each of which is composed of a vulcanized material, such as vulcanized natural or synthetic rubber. The first sealing ring 11 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com