Fault detection and classification (FDC) using a run-to-run controller

一种控制器、故障状态的技术,应用在通用控制系统、程序控制、全面工厂控制等方向,能够解决FDC系统和R2R控制器集成未被实现等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The development of semiconductor processing technology requires the provision of run-to-run (R2R) control at the tool level of semiconductor processing equipment. For stable and robust control of the process, fault detection and classification also needs to be provided at the semiconductor processing equipment tool level. However, simple fault detection techniques are incompatible with R2R control and have the potential to generate frequent false alarms. Advanced process control integrated systems including data collection, data analysis, FDC, R2R control, automatic DOE, SPC charting, PCA and PLS analysis can be used to provide the accurate and reliable process control required by manufacturers of high-performance semiconductor integrated circuits.

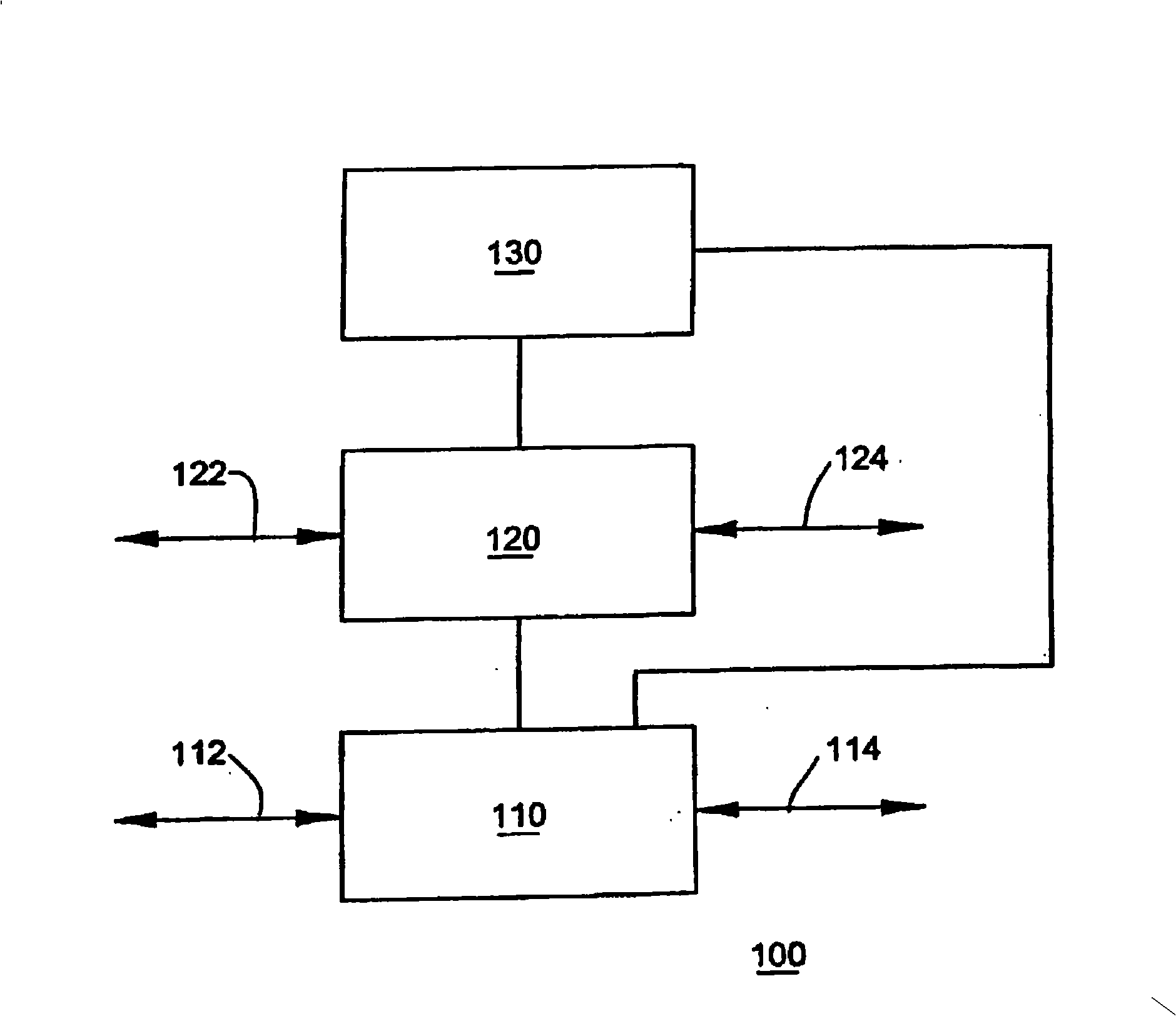

[0021] figure 1 An exemplary block diagram of a processing system according to an embodiment of the invention is shown; in the illustrated embodiment, the processing system 100 includes a processing tool 110, a controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com