Portable die cleaning apparatus and method thereof

A cleaning equipment, portable technology, applied in the direction of discharge tube, electrical components, plasma, etc., can solve problems such as hindering the molding process, achieve the effect of clean removal, reduce environmental pollution, and reduce inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Best Mode for Carrying Out the Invention

[0026] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

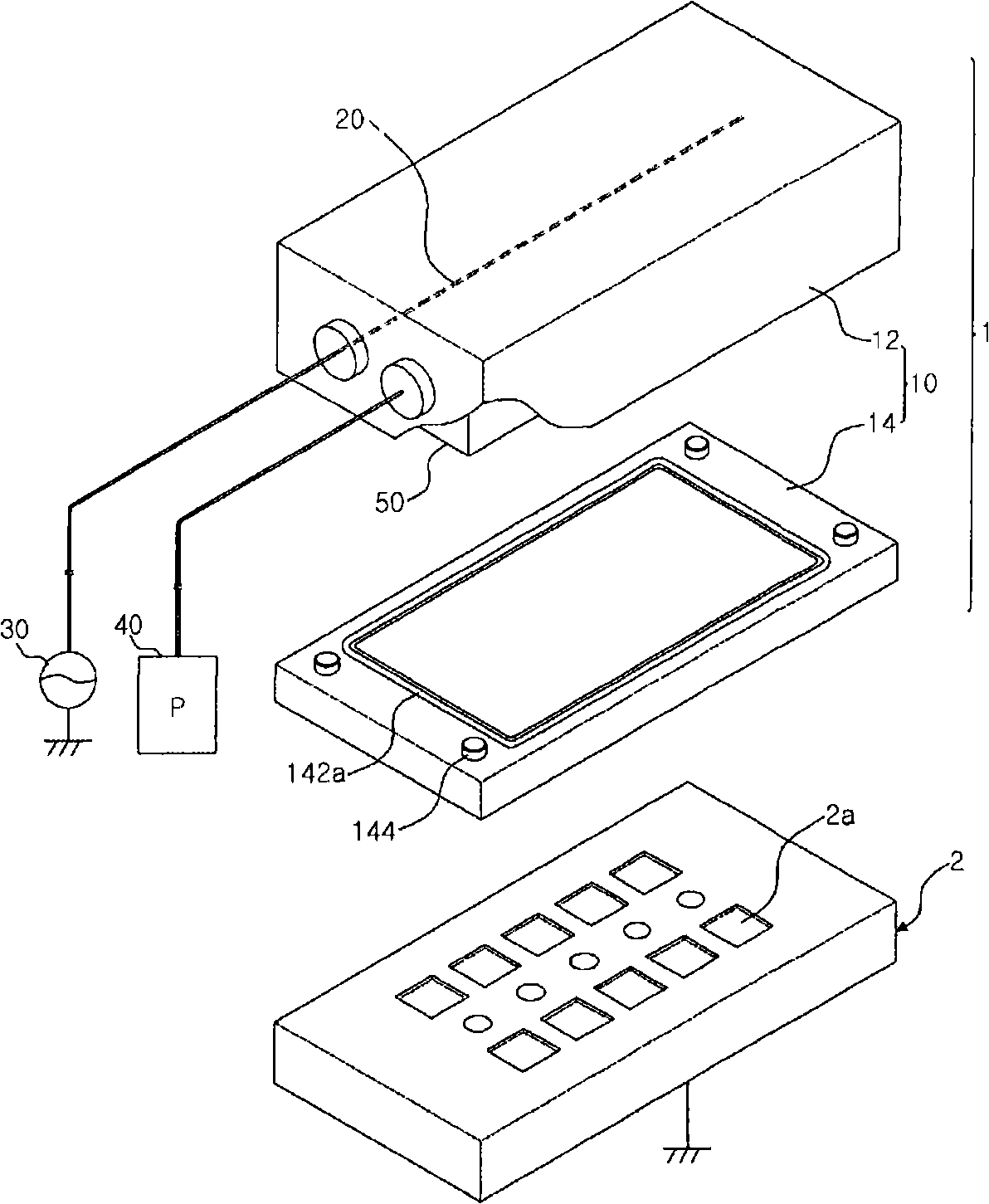

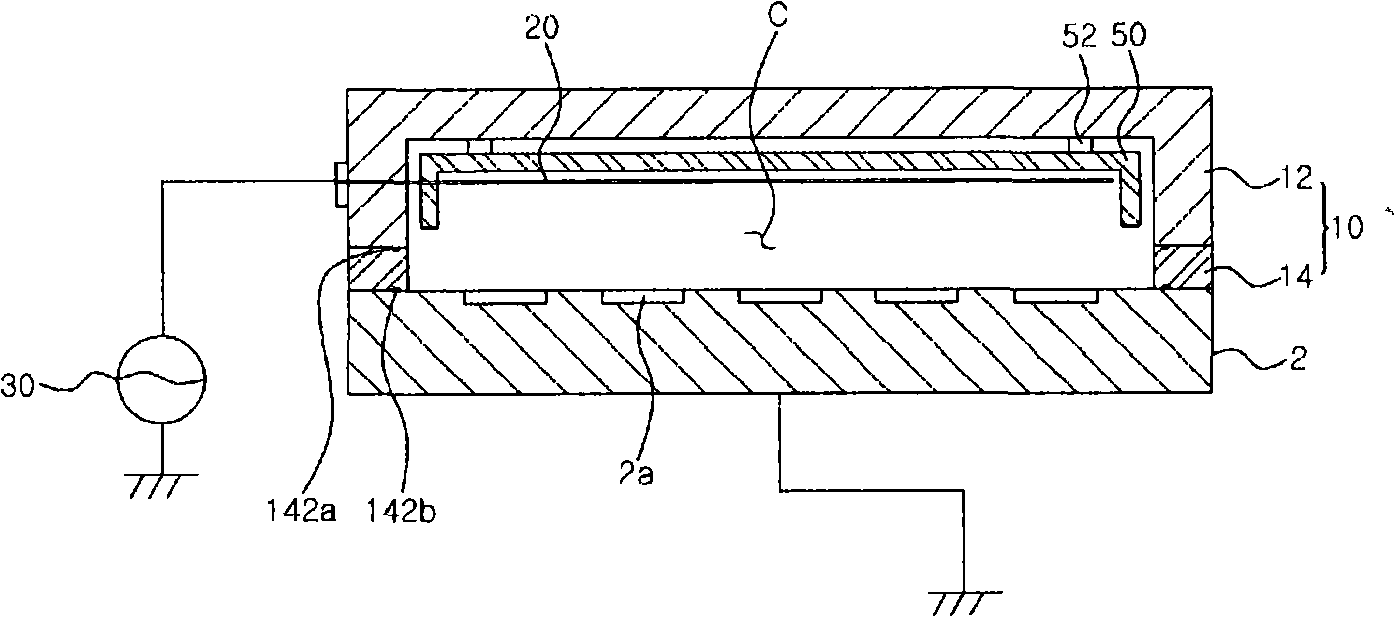

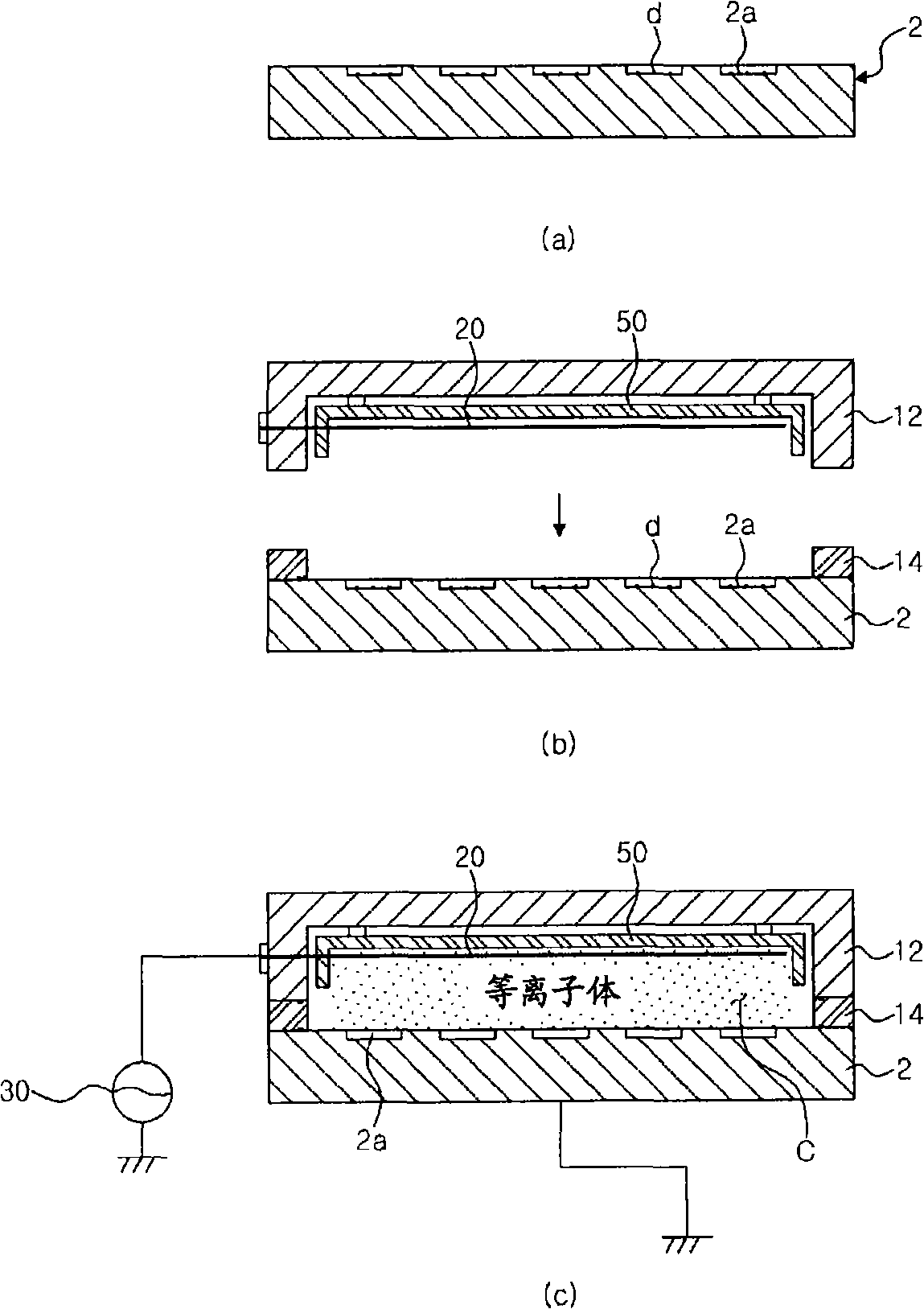

[0027] figure 1 is an exploded perspective view illustrating a mold cleaning device according to an embodiment of the present invention together with a mold to be cleaned, and figure 2 is a schematic drawing figure 1 A cross-sectional view of the state where the mold cleaning device shown in is fixed to the mold.

[0028] Such as figure 1 and figure 2 As shown in , a mold 2 to be subjected to surface cleaning is a mold for use in molding semiconductor chips (not shown), and has a plurality of cavities 2a formed therein serving as spaces to be filled with resin during molding s surface. Since the resin residue d (see image 3 ) mainly adheres to the inner surface of the cavity 2a of the mold 2, so it is very necessary to clean the mold 2, especially the surface of the cavity 2a of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com