Short bundle cable stretching caging device and method for stretching and anchoring

A technology of limiting device and steel strand, applied in the field of tensioning and anchoring and tensioning and limiting device for short-strand steel strands, can solve the problems of tediousness and low work efficiency, and achieve the effect of convenient construction method and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

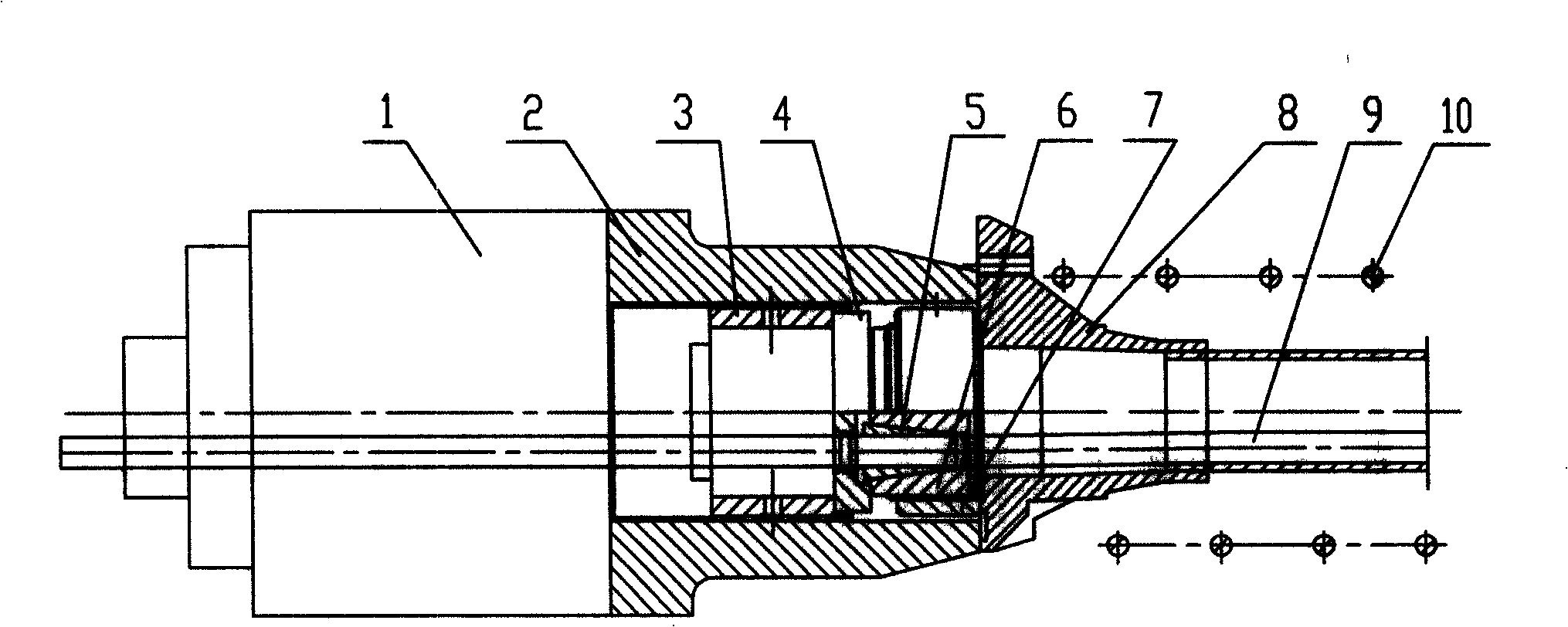

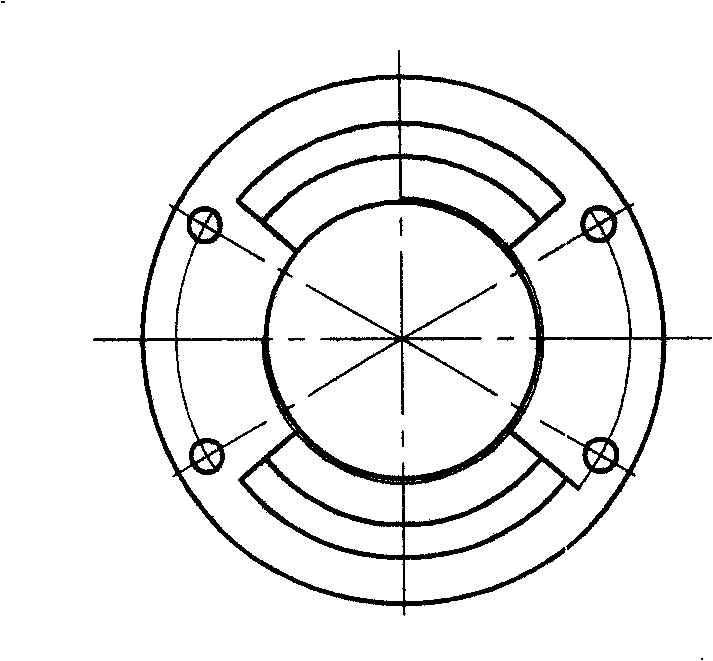

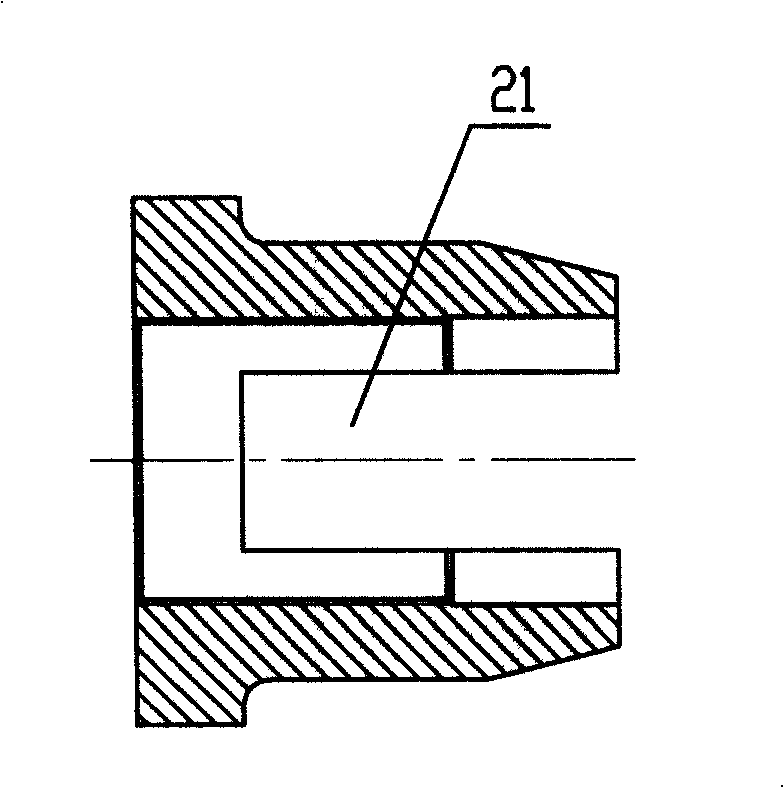

[0016] A short-bundle steel strand tension limiting device is composed of a supporting leg 2, a supporting nut 3 and a limiting plate 4. The supporting leg 2 is a steel cylinder with two symmetrical windows 21. With internal thread, the support nut 3 located in the support leg is a section of steel ring, and four through holes 31 for adjusting the position of the support nut 3 are evenly distributed on the center circumference. The support nut 3 is also provided with an inner part on the support leg. The external thread that matches the thread is connected with the support foot 2. The limit plate 4 is a flat cylindrical steel plate with a through hole 41 for passing the steel strand evenly distributed in the middle and a concave step 42 at the end. The number of through holes 41 on the position plate 4 is the same as the number of clip holes on the anchor plate of the anchor assembly to be stretched. The limit plate 4 is located in the supporting leg 2 and adjacent to the supporti...

Embodiment 2

[0020] The method of using the short-stranded steel strand tension limit device for tension and anchoring.

[0021] Using the short-bundle steel strand tensioning and limiting device composed of the supporting legs 2, the supporting nut 3 and the limiting plate 4 described in the first embodiment, the components to be tensioned are mainly composed of the clip 5, the anchor plate 6, and the anchor nut 7. Anchor backing plate 8 and steel stranded wire 9 are formed. One end of the supporting leg 2 of the short-stranded steel strand tension limit device is supported on the anchor backing plate 8, and the other end is connected to the jack 1 by bolts, and the supporting nut is adjusted. The position of 3 realizes the operation of the first tension and the second tension: during the first tension, the supporting nut 3 against the limit plate 4 makes the anchor plate 6 close to the end surface of the anchor pad 8, and the first tension When anchoring, the steel strand 9 is restricted and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com