Engine cylinder lid burning compartment structure

An engine cylinder and combustion chamber technology, applied in engine components, combustion engines, machines/engines, etc., can solve the problems of heat transfer, poor thermal conductivity, and high NOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

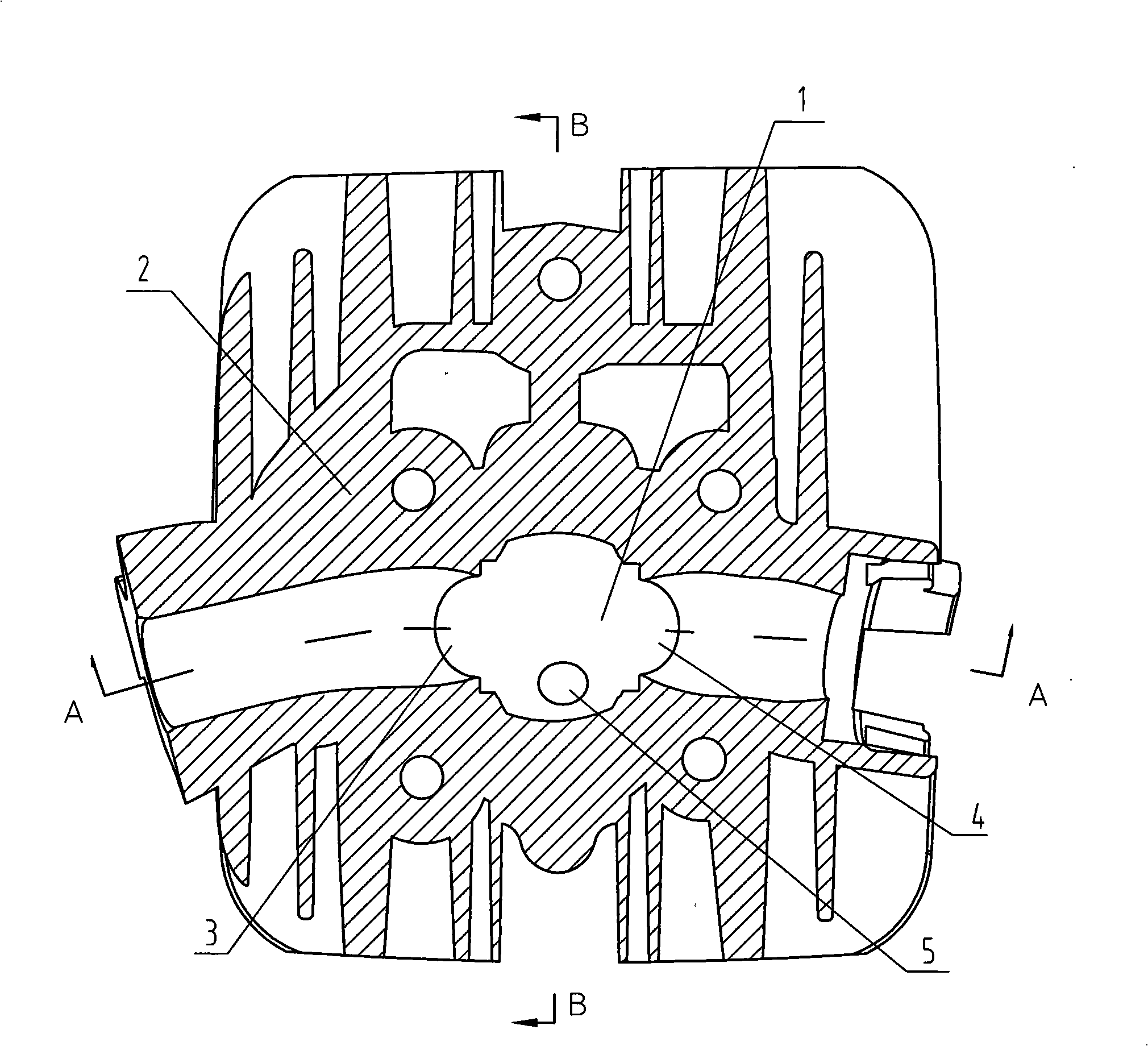

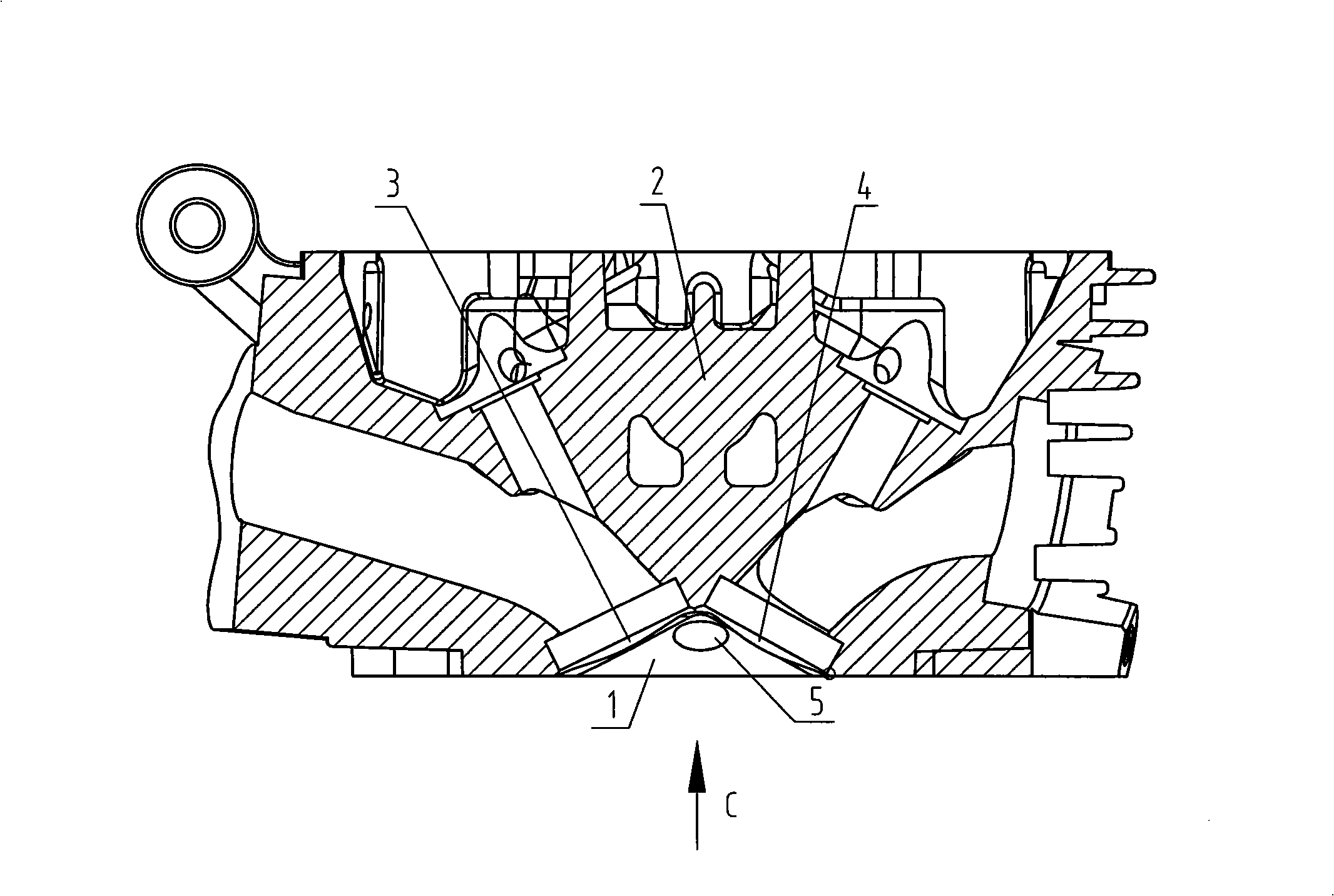

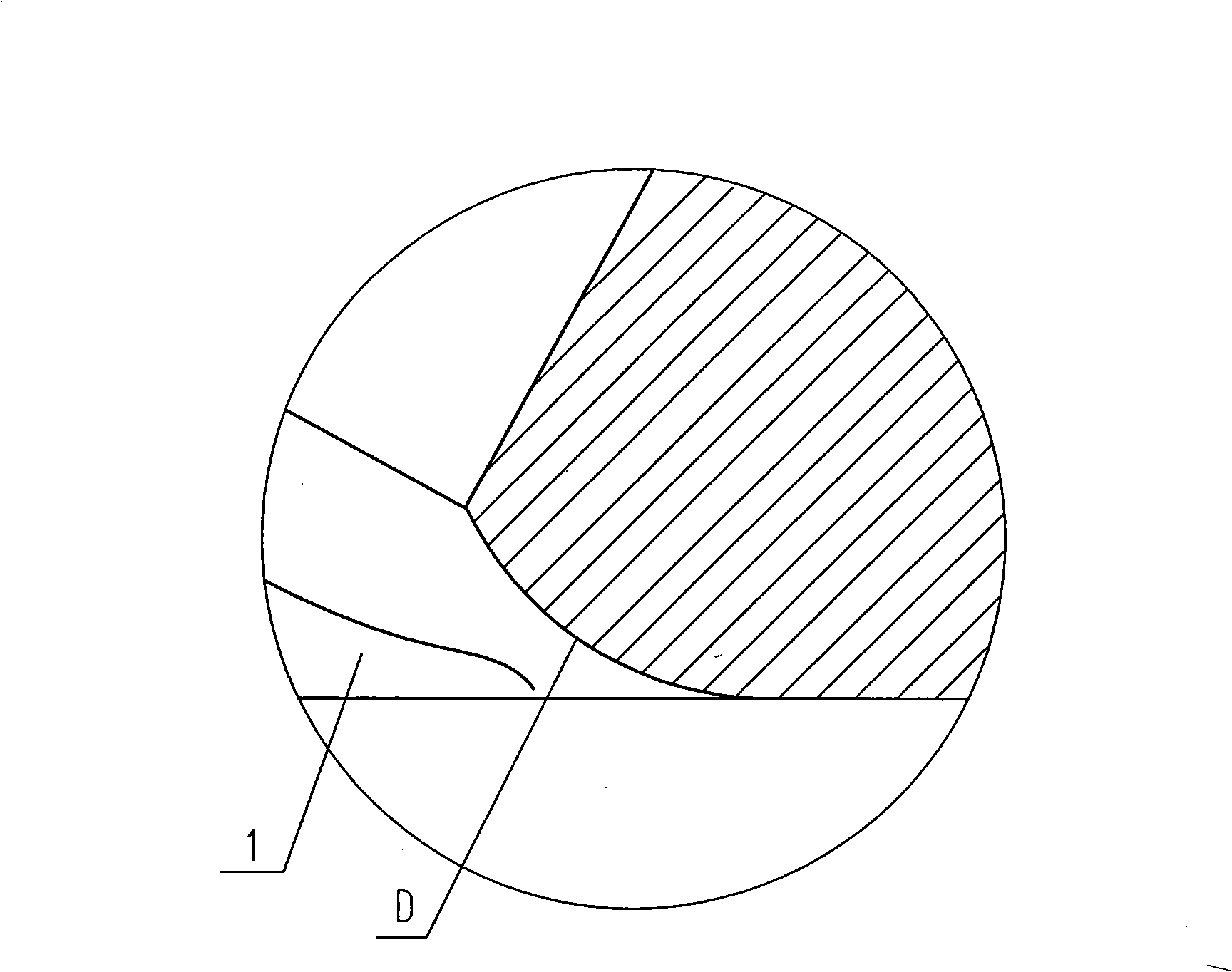

[0014] Such as Figure 1 to Figure 5 As shown, the structure of the combustion chamber on the engine cylinder head of the present invention is: the combustion chamber 1 is in the shape of a pit on the cylinder head 2, and the wall of the combustion chamber 1 is provided with inlet and exhaust valve seat mounting holes 3,4 And the spark plug mounting hole 5, D between the outer peripheral edge of the combustion chamber 1 wall and the end face of the cylinder head 2 is a circular arc R transition or a smooth transition.

[0015] After adopting the above structure, the sharp angle between the outer peripheral edge of the combustion chamber 1 wall and the end surface of the cylinder head 2 is eliminated, so that no dead angle will be formed at the outer peripheral edge of the combustion chamber 1 wall during heat conduction, so that the heat conduction is smooth....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com