Method for carrying out uncatalyzed direct oxidation treatment on gas containing nitric oxide by using Venturi oxidizer

A nitrogen oxide and oxidation treatment technology, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation, can solve the problems of low purification efficiency, high operating cost, and insufficient mixing, and achieve high purification efficiency and low operating cost. Low, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

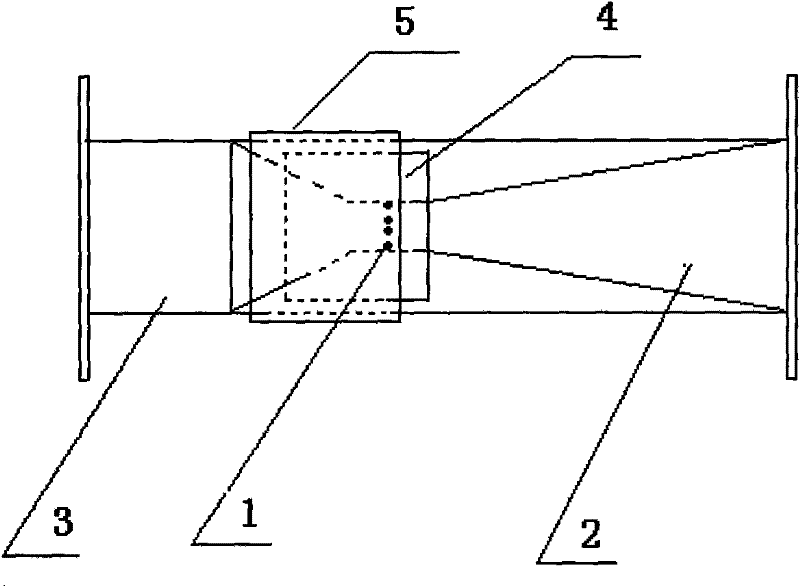

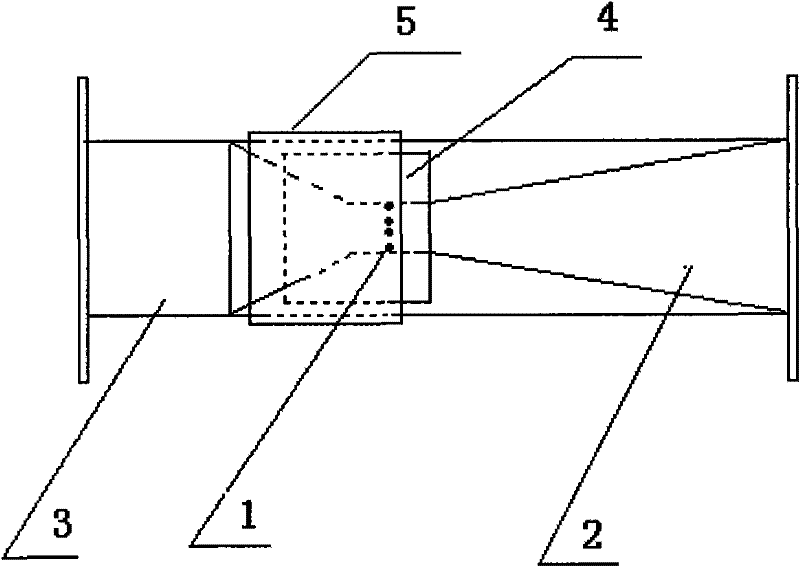

[0033] Venturi oxidizer, structure see figure 1 , including a Venturi tube 2 with an air inlet 1, the outer coaxial sleeve of the Venturi tube is provided with a sleeve 3 that is airtightly connected with it, and the sleeve 3 is provided with an air inlet 4 and an air intake adjustment mechanism 5 . Both ends of the oxidizer are provided with connecting flanges, the air inlet 4 corresponds to the air inlet 1 on the Venturi tube 2 and is evenly distributed on the sleeve 3, and the air intake adjustment mechanism 5 is a sliding gas sleeve set on the outer wall of the sleeve. cover.

[0034] Utilize described venturi oxidizer to carry out the control of nitromethane tail gas:

[0035] The production of dimethyl sulfate-sodium nitrite method of nitromethane, the production line scale is 3.5T / batch, and the original absorption device is concentrated sodium hydroxide three-stage spraying non-packing tower absorption. A large amount of nitrogen oxide-like yellow smoke is produced d...

Embodiment 2

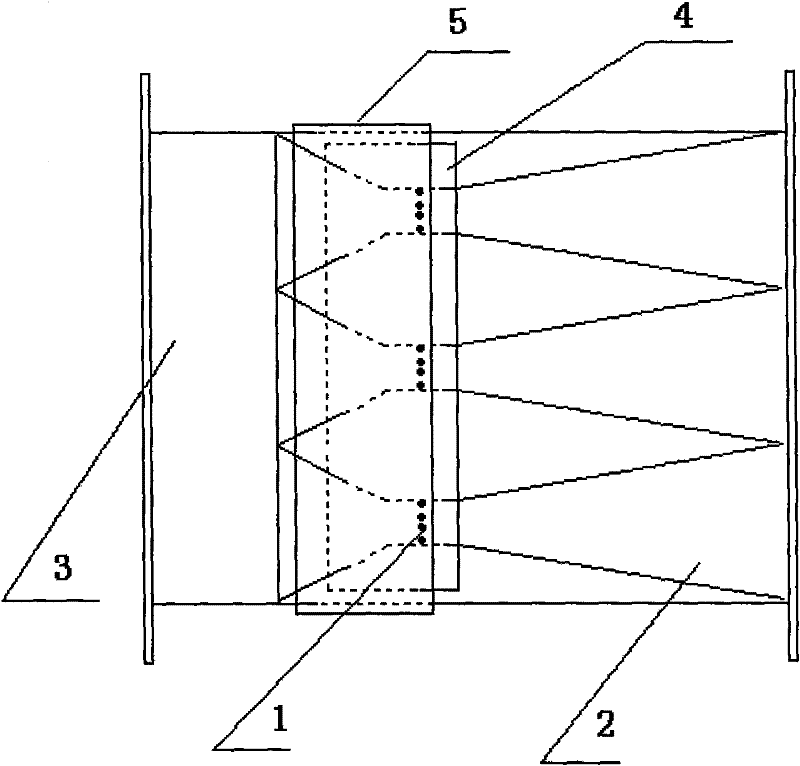

[0037] Venturi oxidizer, structure see figure 2 , the Venturi oxidizer is in the form of a multi-tube structure, and the Venturi tube part is composed of three independent Venturi tubes connected in parallel. Others are the same as embodiment 1.

[0038] Utilize described Venturi oxidizer to carry out the elimination of yellow smoke in nitric acid production (laboratory simulation):

[0039] The laboratory simulates nitric acid tail gas emission, and the nitrogen oxide content in the tail gas is 5000mg / Nm 3 . The treatment combination adopted is: oxidation→oxidation→water absorption→oxidation→water absorption→oxidation→dilute alkali absorption, and the dilute alkali is ammonia water with a concentration of 5% by weight. The content of nitrogen oxides in the tail gas after dilute alkali absorption is lower than 150mg / Nm 3 , the water absorption part gets dilute nitric acid, and the dilute alkali absorption part gets ammonium nitrate. The oxidation process is: let the exha...

Embodiment 3

[0041] Tail Gas Treatment of Caproic Acid Production by Nitric Acid Oxidation

[0042]A large amount of nitric oxide-like yellow smoke is produced during nitric acid oxidation to produce hexanoic acid. The original method of passing oxygen into the tail gas and absorbing it with 10% NaOH solution still cannot eliminate the yellow smoke. Existing tail gas adopts secondary oxidation absorption combination, the absorption liquid is the sodium hydroxide dilute solution of concentration 0.1% by weight, that is: let the tail gas pass through the Venturi oxidizer in the embodiment 1, and enter from the side wall of the Venturi oxidizer by self-absorption The air or oxygen is mixed evenly, fully oxidized, and then absorbed; the absorbed tail gas repeats the above oxidation and absorption process once; the yellow smoke is effectively eliminated, and the product obtained by absorption is sodium nitrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com