Semiconductor device and method of manufacturing same

A semiconductor and housing technology, which is applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, and semiconductor/solid-state device components, etc., can solve the problems of difficulty in automatic operation of assembly robots, dependence, and longer order-to-delivery period, etc. Achieve the effect of improving wire bonding efficiency and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

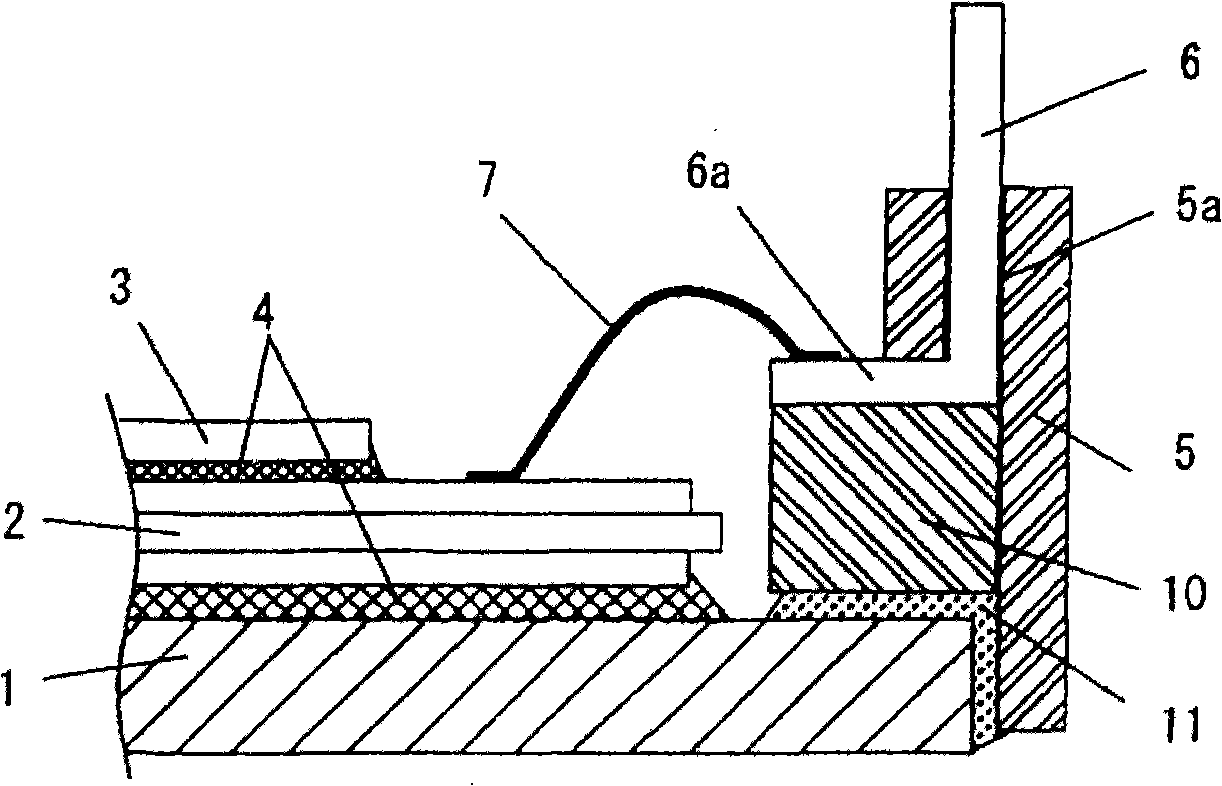

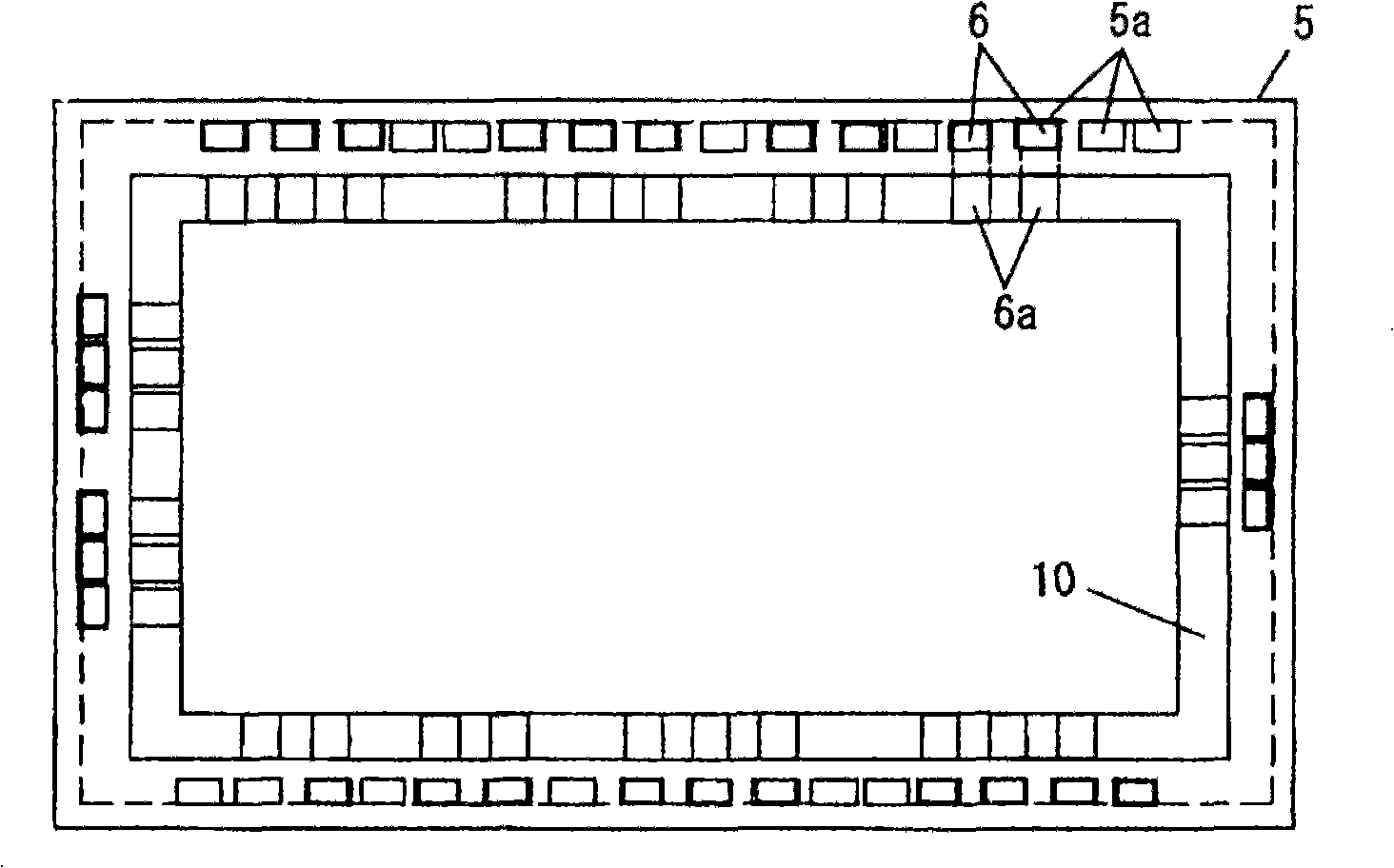

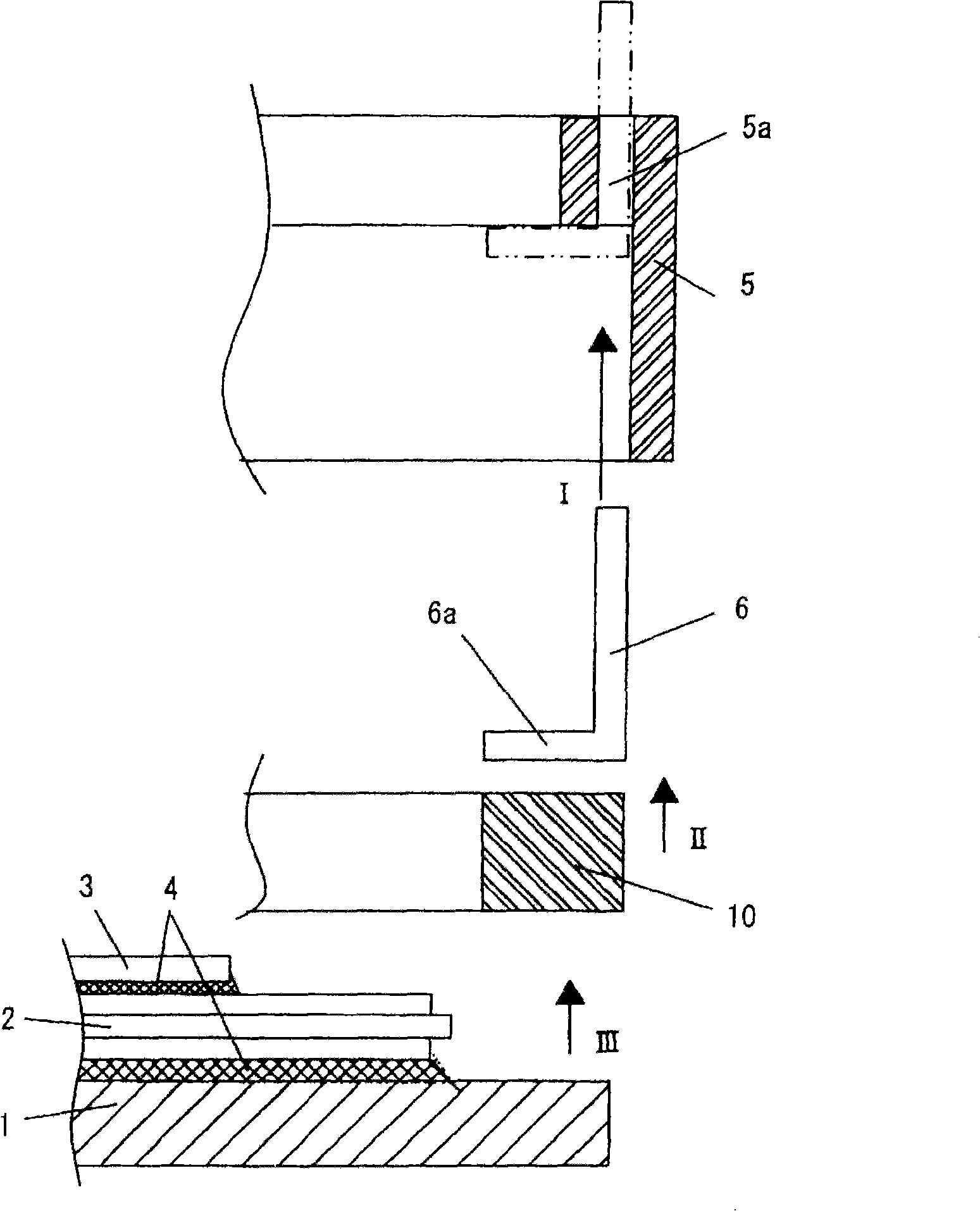

[0056] First, use figure 1 , figure 2 The assembly structure of the package according to the embodiment of the present invention will be described. This example is the same as Figure 11 Compared with the terminal-integrated structure in which the external terminal 6 is insert-molded on the peripheral resin case 5 such as the above-mentioned conventional structure, it is different in the following points. That is, in the illustrated embodiment, along the peripheral wall of the peripheral resin case 5 , terminal attachment holes 5 a are formed in advance at a plurality of positions aligned at predetermined intervals. Wherein, the terminal mounting hole 5a is formed by setting a center corresponding to the terminal mounting hole on the molding die during the molding process of the peripheral resin case 5 and then punching it. In addition, when assembling the package, the hole for mounting the external terminal 6 is selected from the above-mentioned terminal mounting hole 5a...

Embodiment 2

[0070] Next, use Figure 6 ~ Figure 10 , a second embodiment that further improves the package structure of the above-mentioned embodiment 1 will be described. In this embodiment, the following structures are added to the peripheral resin case 5 and the terminal fastening frame 10 . That is, a concave-convex step portion 5 b is formed on the upper surface side along the peripheral wall portion of the peripheral resin case 5 . The concave-convex step portion 5b is formed so that the recessed portion 5b-1 is located in the middle of the adjacent terminal attachment holes 5a to match the arrangement pitch of the terminal attachment holes 5a. Thus, if Figure 10 As shown in (a), a creepage distance d larger than the space distance is formed between the external terminals 6 drawn outward from the peripheral resin case 5 , and high insulation resistance can be ensured.

[0071] On the other hand, regarding the terminal fastening frame 10, press-fit protrusions 10a having a V-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com