False sticker and film sticking method

A fake machine and machine sticker technology, applied in the application of non-metallic protective layer, secondary processing of printed circuits, etc., can solve problems such as misjudgment and difficulty in inspection, achieve accurate control, improve personnel work efficiency, and simple equipment structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

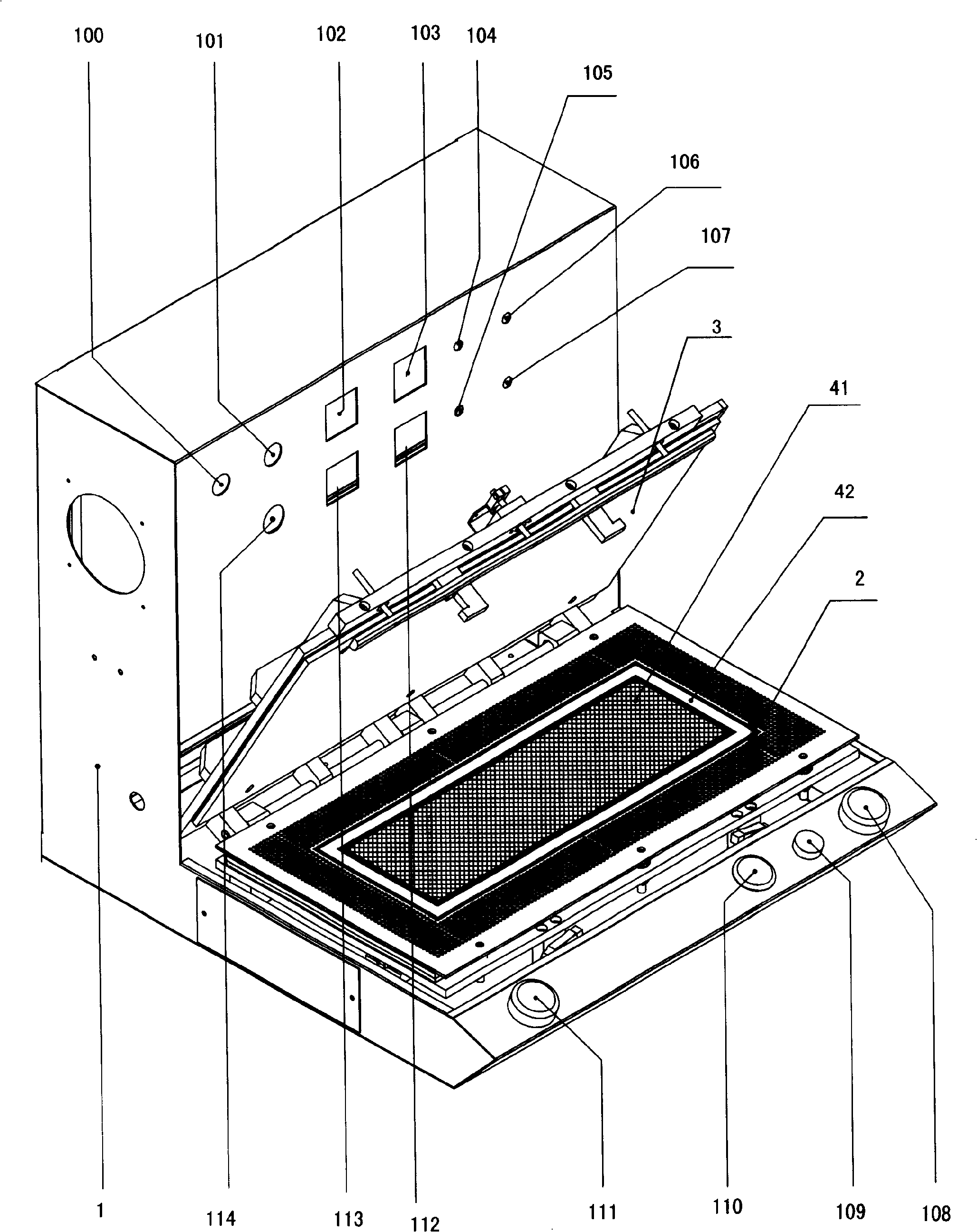

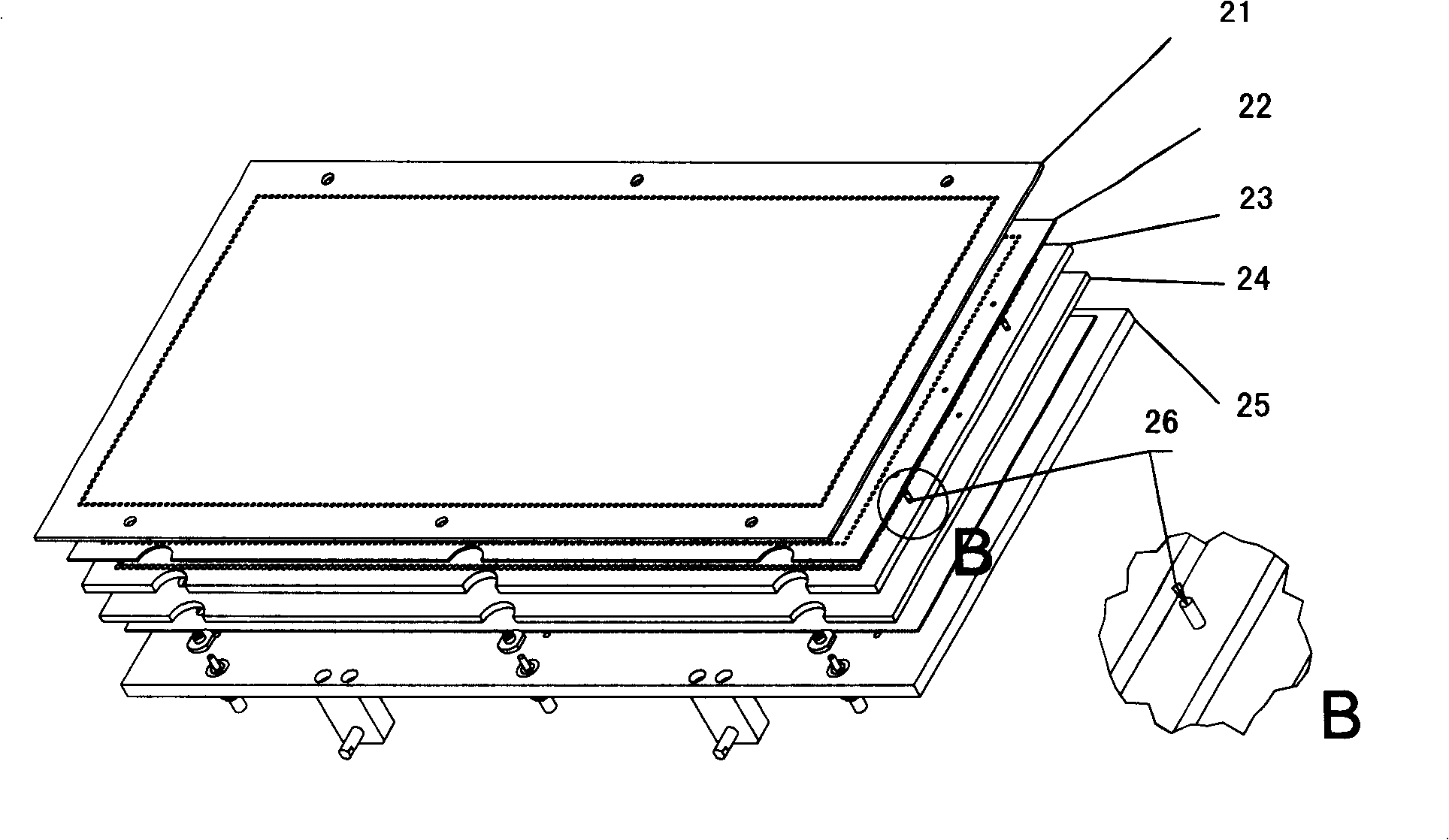

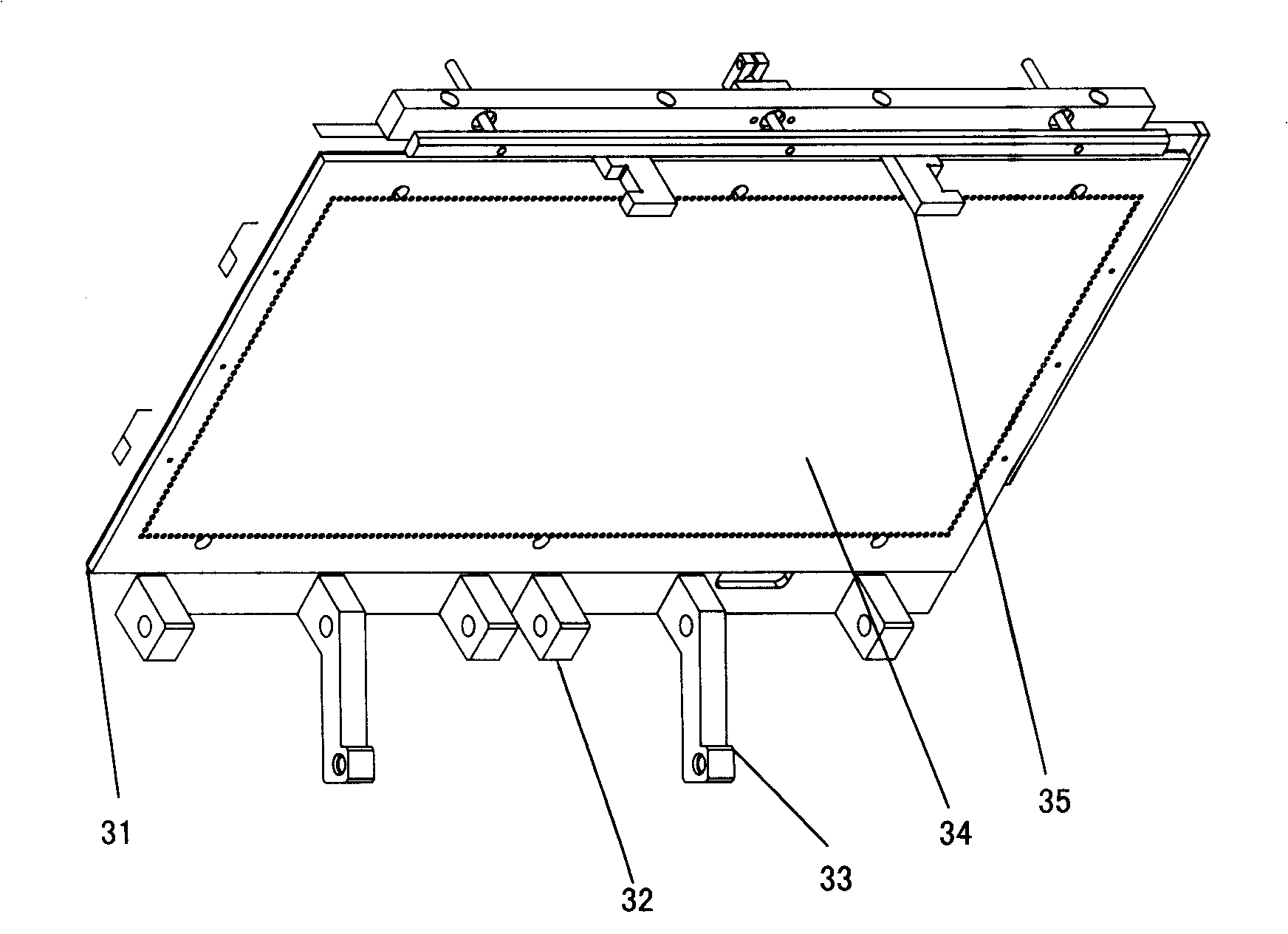

[0035] Such as figure 1 , 2 As shown, the false pasting machine of the present invention includes a chassis frame 1 and a control circuit, and the chassis frame is provided with an upper installation surface and a lower installation surface intersecting into an angle, and the upper installation surface or the lower installation surface are provided with There are operation or display devices, wherein, the false sticker machine also includes an upper template assembly 3 and a lower template assembly 2, and the upper template assembly 3 and the lower template assembly 2 are installed on the chassis frame 1, and the lower template assembly 2 is located on the Above the lower mounting surface of the chassis frame 1; the lower formwork assembly 2 includes a plurality of positioning pins 26 that can be aligned with the fitting position, and the upper formwork assembly 3 is provided with a relief device for the positioning pins 26; When the machine is in the working state, the lower...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap