Non-oriented electrical steel head and tail flash welding technique

A technology of grain-oriented electrical steel and process method, applied in the field of non-oriented electrical steel head and tail flash welding, can solve the problems of electrical steel welding seam easily broken belt, high maintenance technical requirements, deterioration of welding seam performance, etc., and achieve good plasticity and toughness. , no overlap phenomenon, the effect of improving the quality of the weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

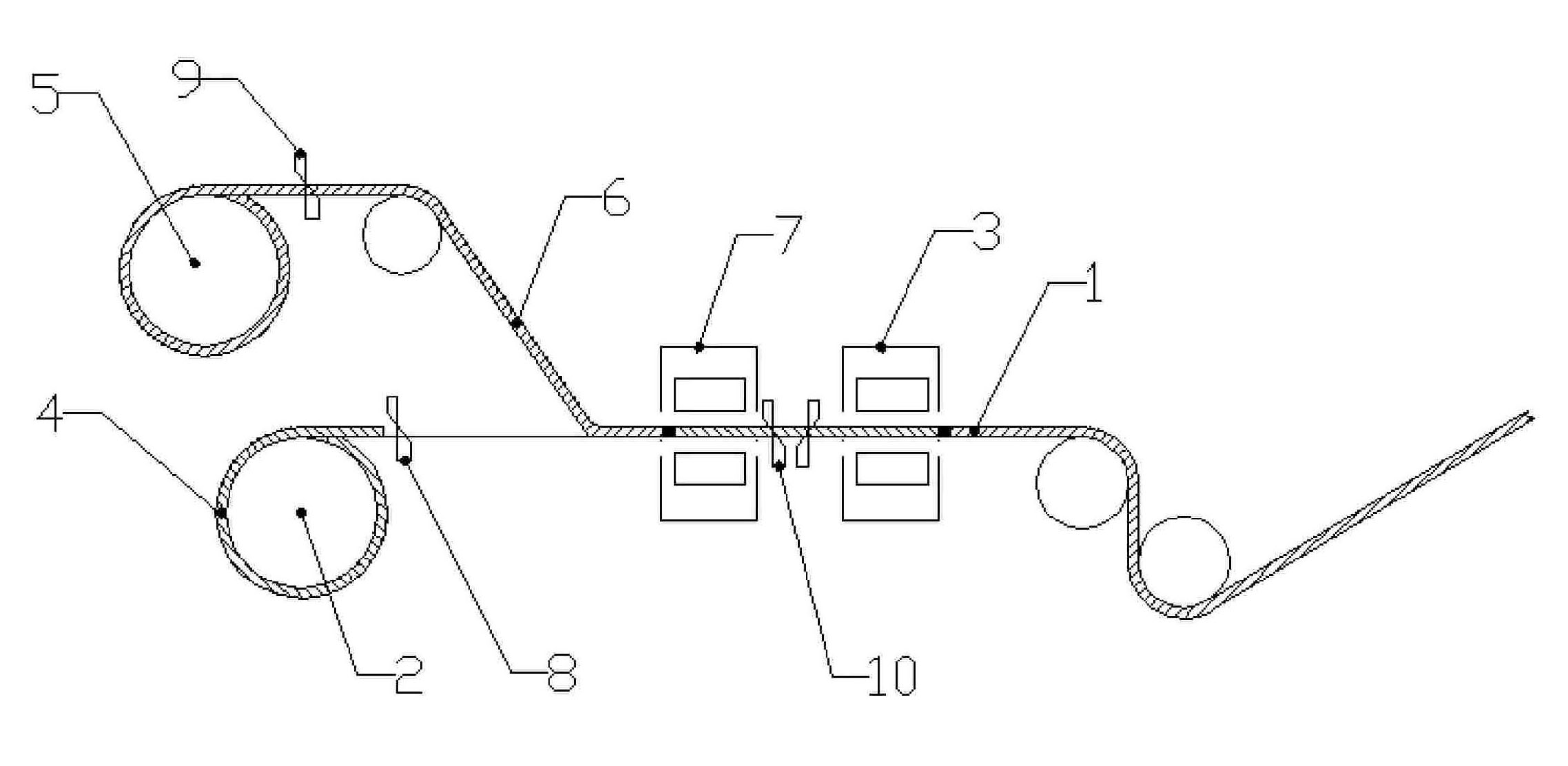

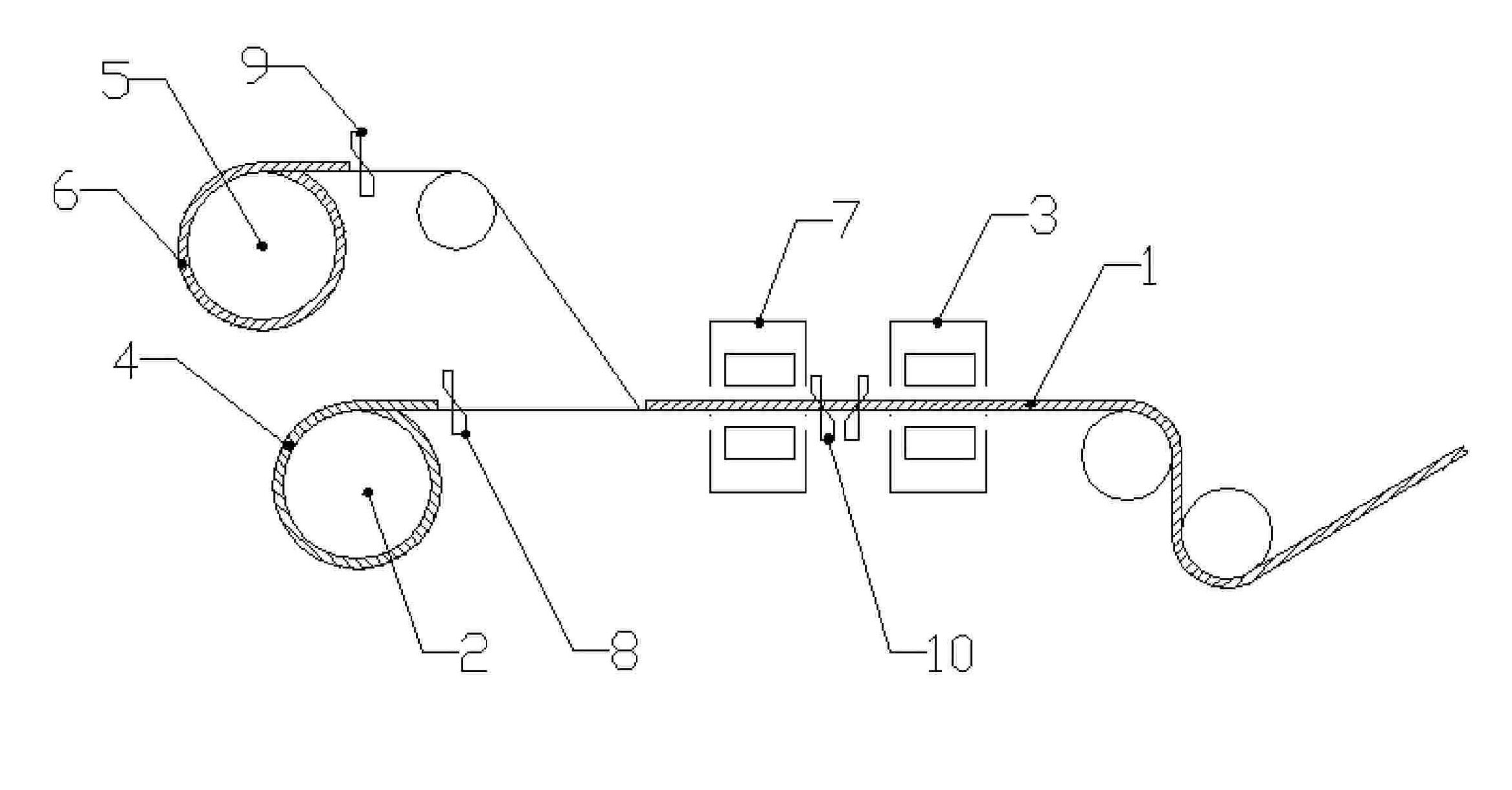

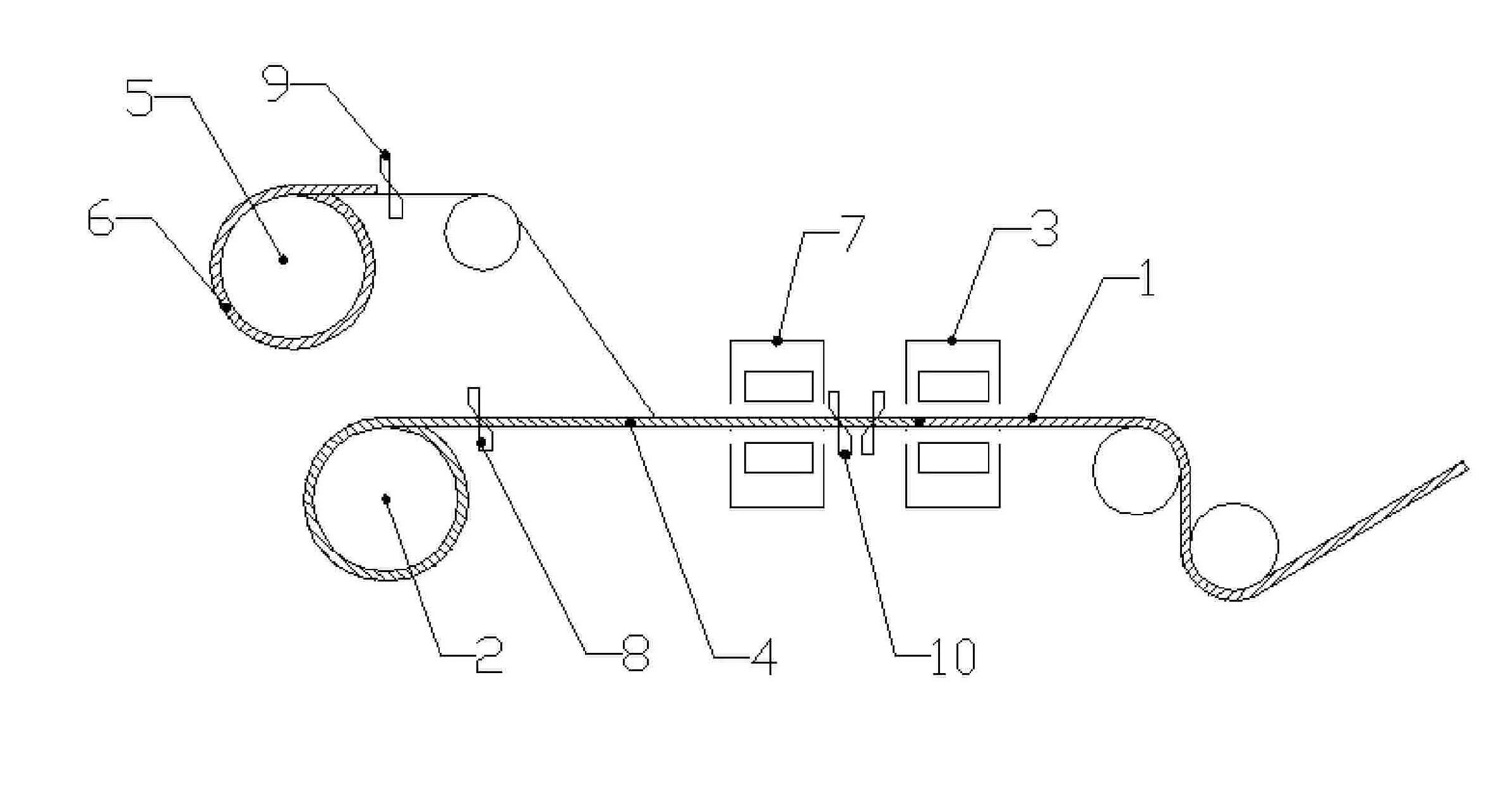

[0033] Example 1: In the combined cold-rolling and acid-rolling unit, the current coil of non-oriented electrical steel 1 enters the acid tank, and after the tail leaves the first coiling position 5, the rear coil of non-oriented electrical steel 6 is placed at the first coiling position 5 , the DX series low-carbon and low-silicon steel series steel 4 of the same thickness and width are placed on the second winding position 2, and the low-carbon and low-silicon steel series steel 4 can be reciprocated forward and backward at the second winding position 2. Return materials. After the tail of the pre-rolled non-oriented electrical steel 1 that has entered the acid tank and the head of the low-carbon and low-silicon steel series steel 4 of the DX series complete the first flash welding, the low-carbon and low-silicon steel series steel 4 at the second winding position 2 Drive the welded seam back to the electrode 7 side of the movable end of the welding machine, the shear knife ...

Embodiment 2

[0034] Example 2: In the combined cold-rolling and acid-rolling unit, the current coil of non-oriented electrical steel 1 enters the acid tank, and after the tail leaves the first coiling position 5, the rear coil of non-oriented electrical steel 6 is placed at the first coiling position 5 , IF series low-carbon and low-silicon steel series steel 4 of the same thickness and width are placed on the second winding position 2, and the low-carbon and low-silicon steel series steel 4 can be reciprocated forward and backward at the second winding position 2 Return materials. After the tail of the pre-coiled non-oriented electrical steel 1 that has entered the acid tank and the head of the low-carbon and low-silicon steel series steel 4 of the IF series complete the first flash welding, the low-carbon and low-silicon steel series steel 4 at the second winding position 2 Drive the welded seam back to the electrode 7 side of the movable end of the welding machine, the shear knife 9 cut...

Embodiment 3

[0035] Example 3: In the combined cold-rolling and acid-rolling unit, the current coil of non-oriented electrical steel 1 enters the acid tank, and after the tail leaves the first coiling position 5, the rear coil of non-oriented electrical steel 6 is placed at the first coiling position 5 The low-carbon and low-silicon steel series steel 4 of the St series with the same thickness and width is placed on the second winding position 2, and the low-carbon and low-silicon steel series steel 4 can be reciprocated forward and backward at the second winding position 2. Return materials. After the first flash welding is completed between the tail of the pre-rolled non-oriented electrical steel 1 that has entered the acid tank and the head of the low-carbon and low-silicon steel series steel 4 of the St series, the low-carbon and low-silicon steel series steel 4 at the second winding position 2 Drive the welded seam back to the electrode 7 side of the movable end of the welding machine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com