Emulsion pressing equipment

A technology for lotion and lotion bottles, which is applied in the field of devices for pumping out lotion in lotion bottles, and can solve the problems of polluting lotion bottles, cleaning the surrounding environment, inconvenient shipment of lotion bottles, and wrongly pumping out lotion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

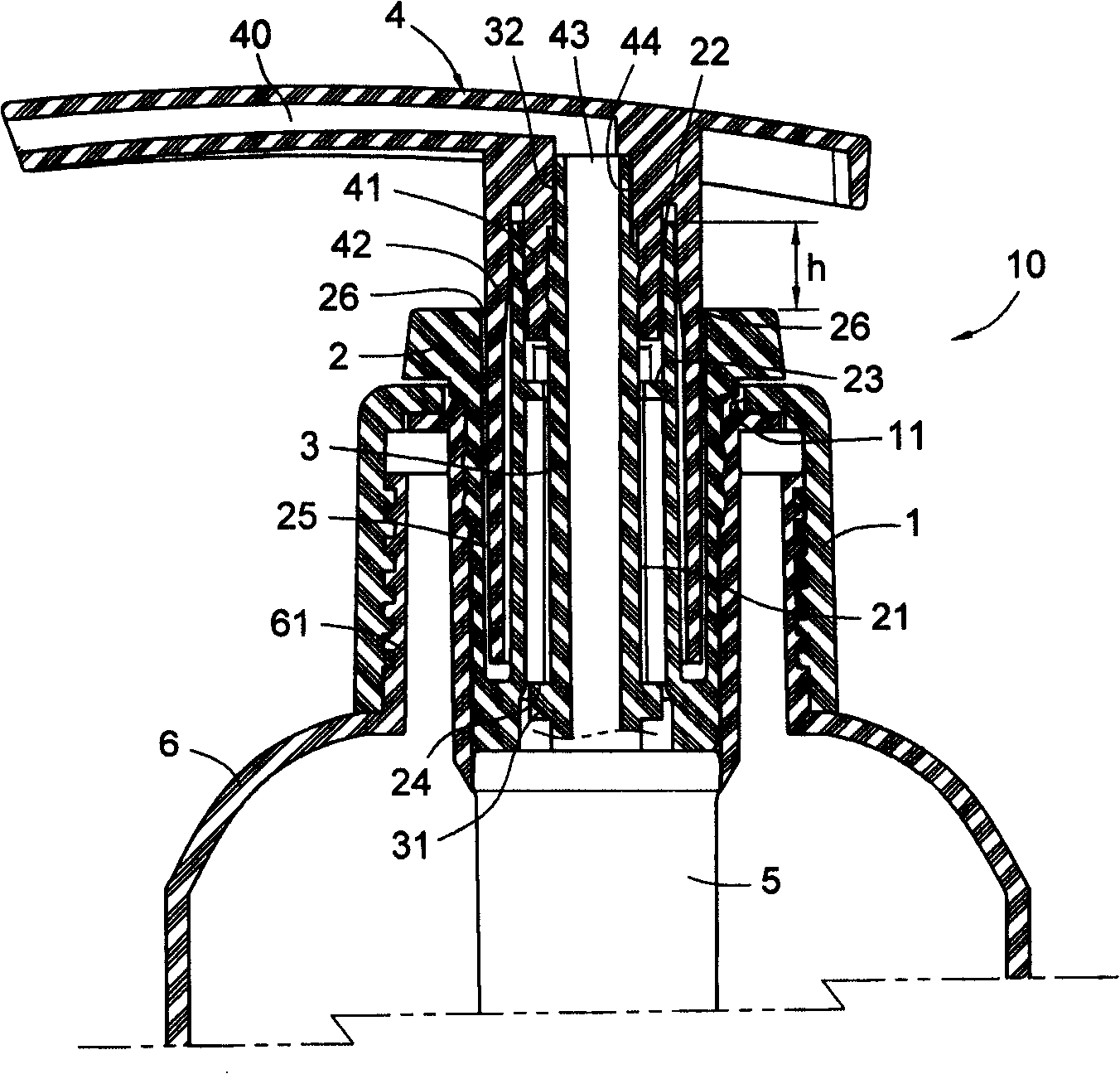

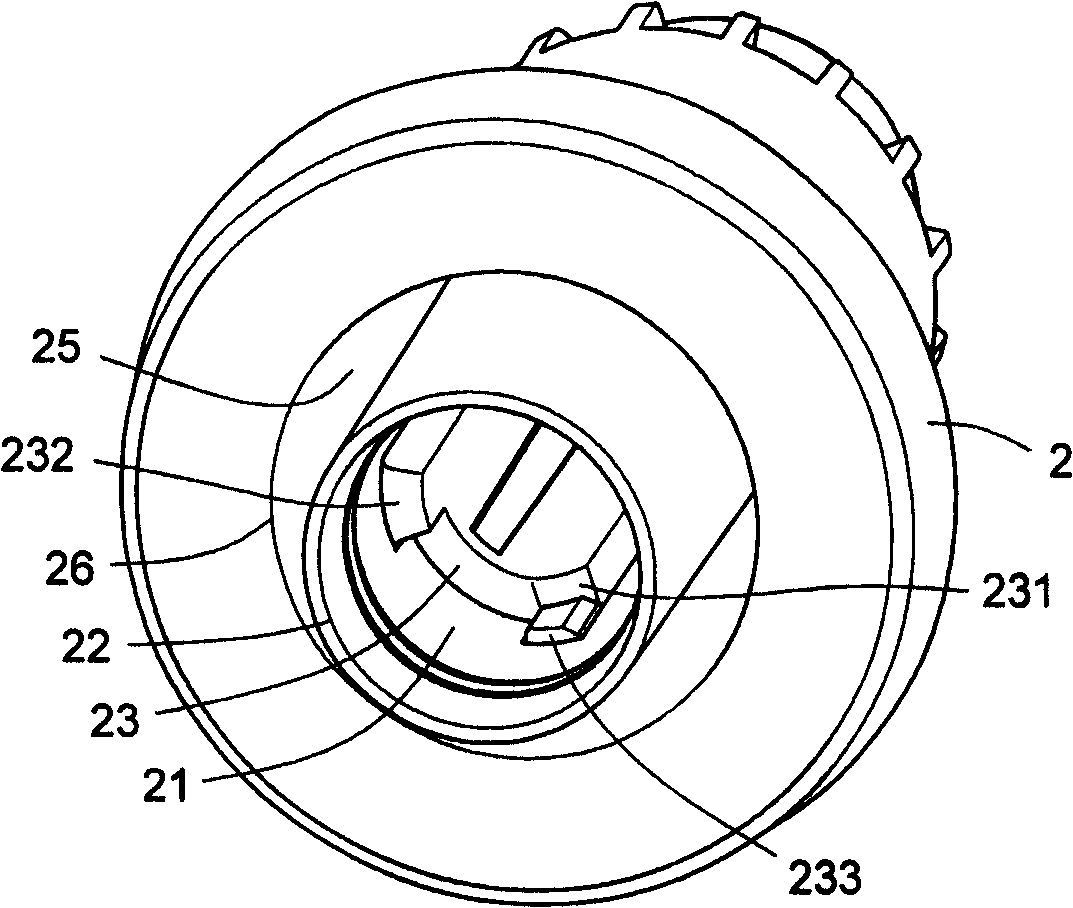

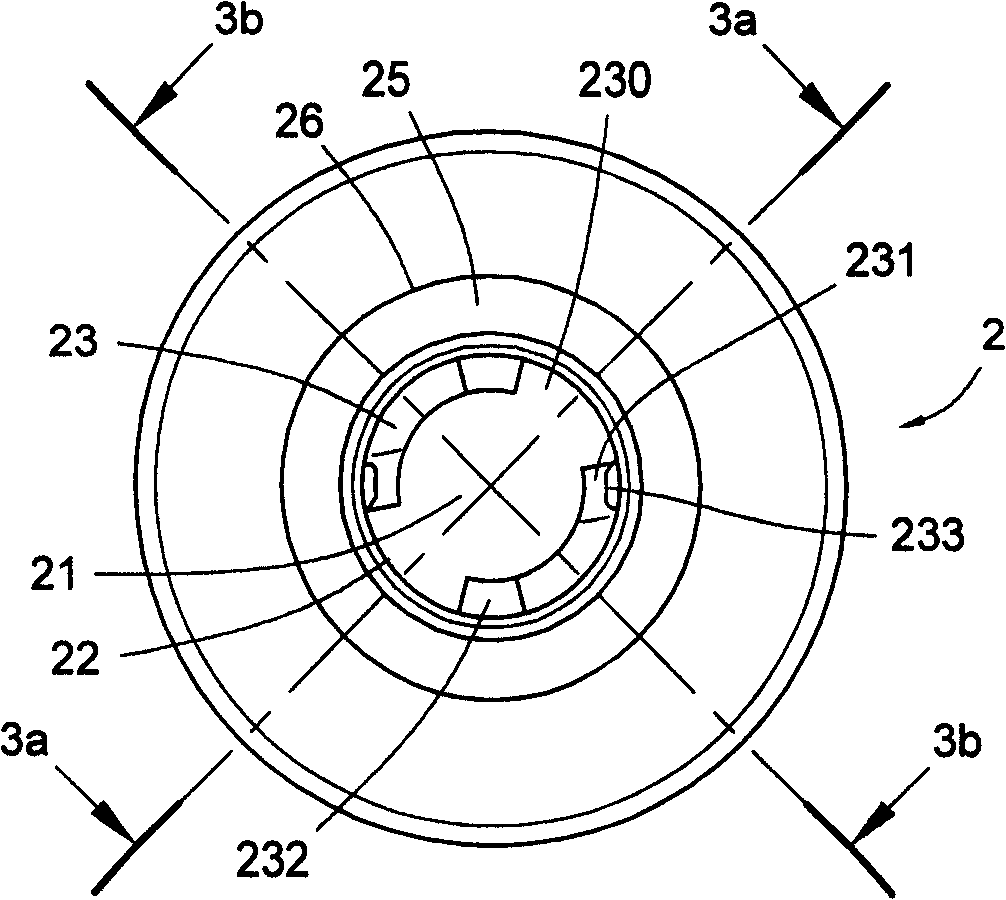

[0041] see figure 1 A partial sectional view of a preferred embodiment of the present invention illustrates that the lotion presser 10 of the present invention is provided with a port 11 on a screw cap 1 to pass through a tube base 2, and the screw cap 1 can be screwed into a On the bottle mouth 61 of the lotion bottle 6; the bottom of the tube base 2 is combined with a pump tube 5 that can pump the emulsion in one direction, and the inside of the tube tube 5 has a valve plug that utilizes the elastic force of the spring to reset and a one-way valve, and the tube base 2 is provided with a through hole 21 communicating with the pump 5, and a conduit 3 capable of guiding the emulsion in the pump 5 is movably pierced in the through hole 21, and the top of the conduit 3 is exposed outside an opening 22 at the top of the through hole 21. An inner sleeve 41 at the bottom of the pressing head 4 is sleeved, and a guide hole 40 is provided on the pressing head 4 to communicate with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com