Resource treatment method for malting sewage

A treatment method and recycling technology, applied in the field of wastewater recycling in the malting industry, can solve the problems of substandard sewage discharge in China, shortage of water resources, etc., to promote development, low comprehensive treatment costs, and solve substandard sewage discharge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

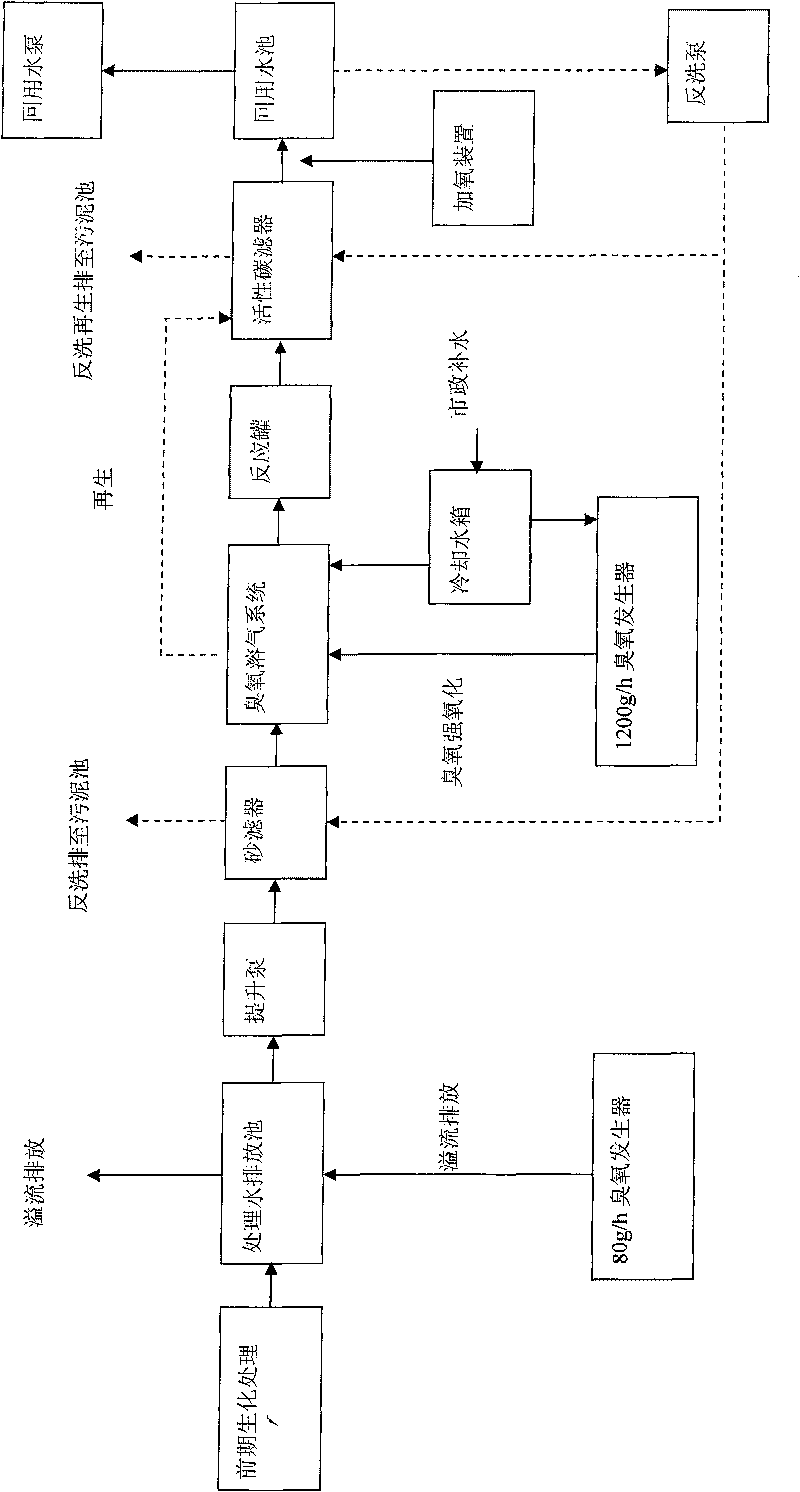

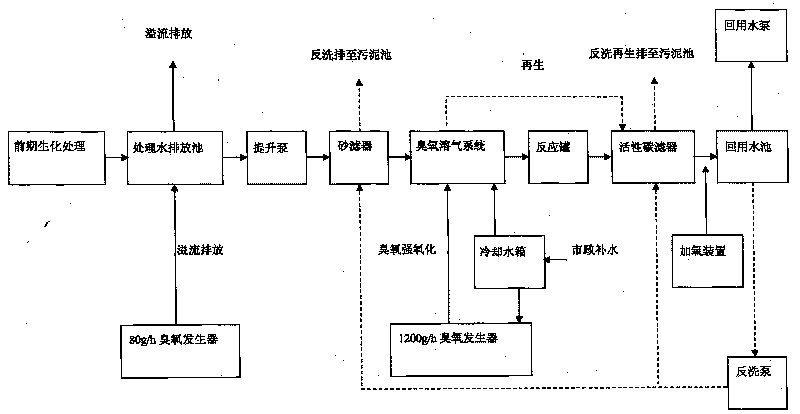

[0026] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] The implementation location is Dalian, Liaoning Province.

[0028] Take 1500 tons of malting sewage, its indicators are: COD cr 2800mg / L, BOD 5 1350mg / L, total polyphenol content 190mg / L, chromaticity (platinum cobalt chromaticity unit) 50, turbidity 40NTU, ss 950mg / L, coliform bacteria 51*10 6 CFU / 100mL, the total number of colonies 43*10 8 CFU / 100mL.

[0029] After removing impurities by the grid machine, adjusting the acidification tank, anaerobic and aerobic aeration, the indicator after the air floats out of the water is: COD cr 170mg / L, BOD 5 58mg / L, total polyphenol content 80mg / L, chroma 40, turbidity 28NTU, ss 60mg / L, N-NH 3 14mg / L, coliform bacteria 36*10 4 CFU / 100mL, the total number of colonies 29*10 5 CFU / 100mL.

[0030] The biochemically treated sewage enters the treated water discharge pool, which has a volume of 80 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com