Device for controlling helical lamp tube formation

A control device, a spiral technology, applied in glass molding, glass re-molding, manufacturing tools, etc., can solve problems such as rigid light refraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

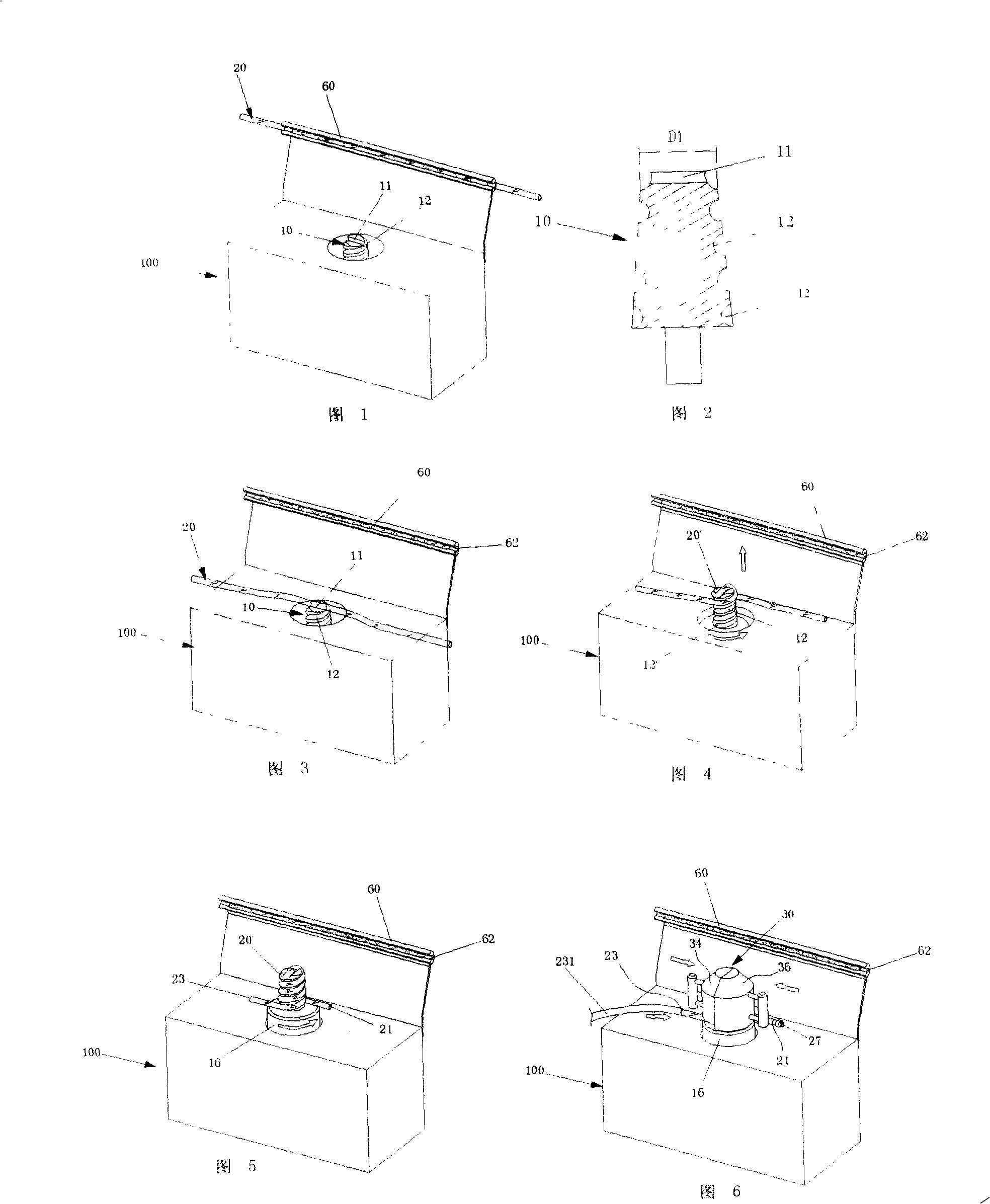

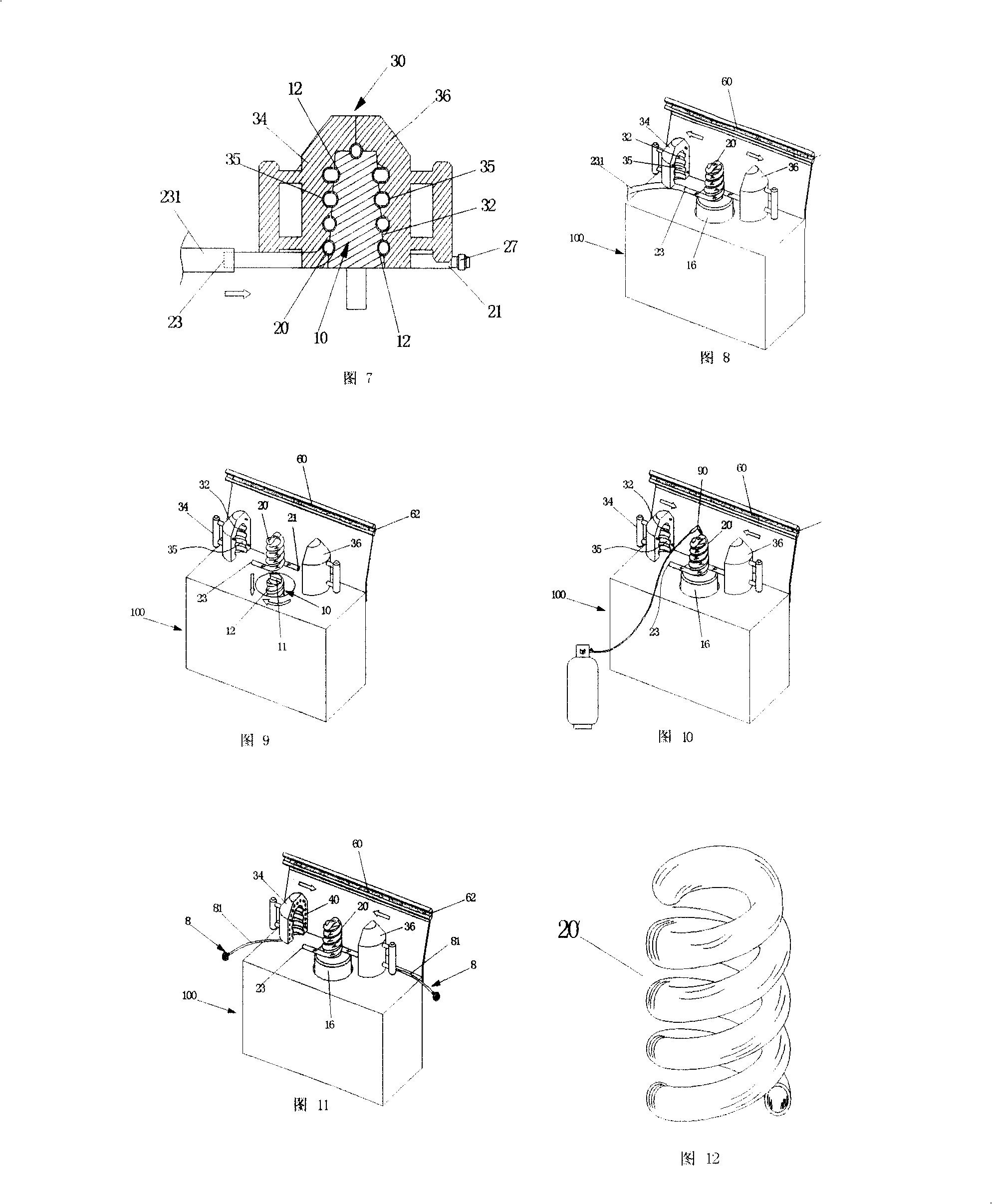

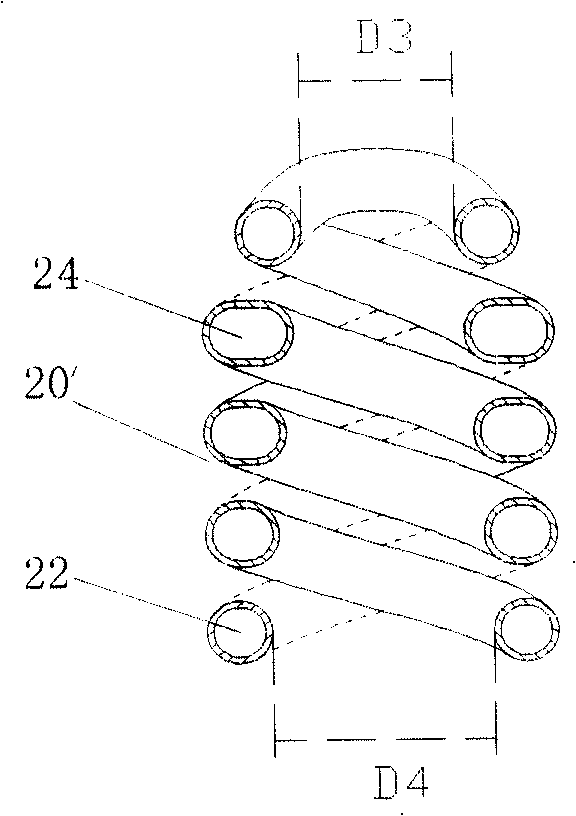

[0032] As shown in Figure 1, the heater 60 is installed above the side of the machine 100, so that the heater 60 is close to the inner mold 10, and its purpose is to operate on the inner mold 10 immediately when the operator takes out the glowing lamp tube 20. , to reduce the heat dissipation time of the lamp tube 20 and increase the plasticity time of the lamp tube 20; at this time, the inner mold 10 is located at the lower fixed point, as shown in Figure 3, after the plastic lamp tube 20 is taken out from the heater 60, its processing temperature is about 700 ° ~ 900°C, right, place the slightly central position of the lamp tube 20 on the transverse groove 11, and start the rotating device 16, as shown in Figure 4, make the inner mold 10 rotate forward and move upward, and the lamp tube 20 The lamp tubes 20 on the two sides of the center go around the spiral groove 12 until the inner mold 10 rises to the upper fixed point in the machine 100 (as shown in Figure 5), and the lam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com