Lock head adopting vane spring idle rotation lock master structure and the key thereof

A marble and blade technology, applied in the field of mechanical locks, can solve the problems of difficult to guarantee processing accuracy, time-consuming processing, complex structure, etc., and achieve the effects of improving safety, reducing costs, and having a simple structure of the lock head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

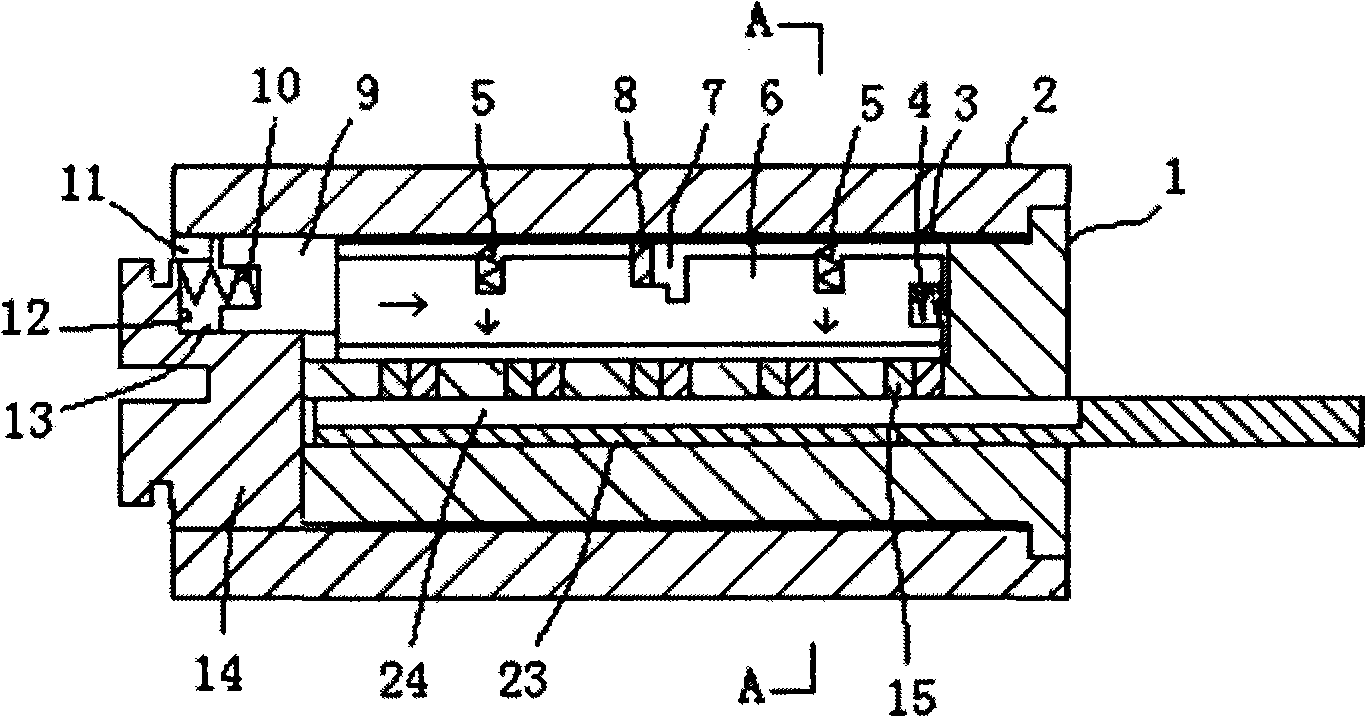

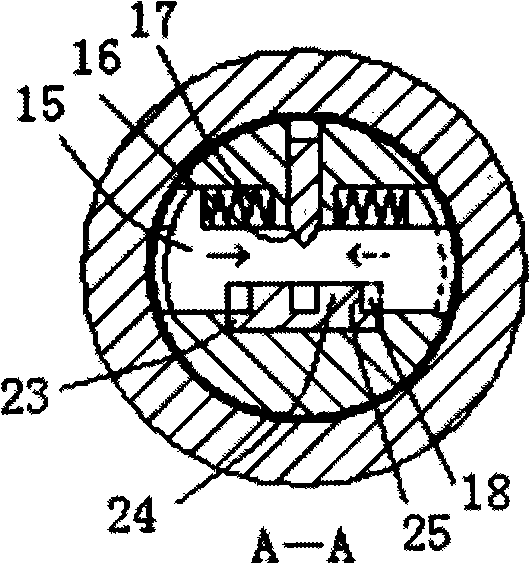

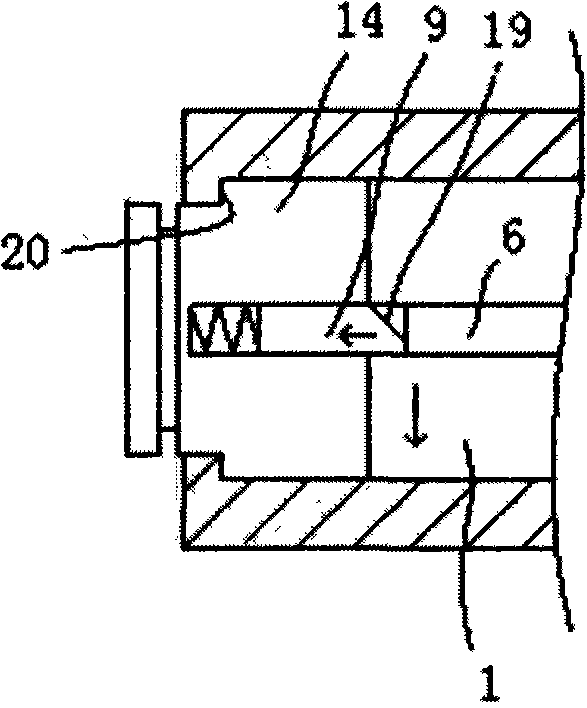

[0019] See Figure 1 to Figure 4 , the lock head of the present invention comprises a lock body 2 and a lock core in the lock body 2, the lock core is divided into a front lock core 1 and a rear lock core 14, and the front lock core is provided with a number of two blade pins 15 along the axis. One set of blade pins, the locking side column groove on the front lock cylinder 1 is provided with a locking side column 6 that can match the V-shaped groove 16 on the blade pins, and the locking side column 6 is provided with a stepped groove 7 , the upper part of the locking side post groove is provided with a card 8 and a fixing part that matches the stepped groove 7 on the locking side post. Locking side post radial return spring 5 is arranged between, is provided with locking side post axial return spring 4 between locking side post 6 and the end wall of locking side post slot; The inner locking side column groove is correspondingly provided with a lock pin chute 13, and the lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com