Self-locking mill/lathe tool installation mechanism easy to mount or dismount

An installation mechanism, easy assembly and disassembly technology, applied in the direction of tool clips, manufacturing tools, metal processing machinery parts, etc., can solve problems such as installation and withdrawal of tools, achieve stable and reliable connections, improve work efficiency, and disassemble and replace tools easily. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0018] In this embodiment, a CNC machine tool is taken as an example for illustration.

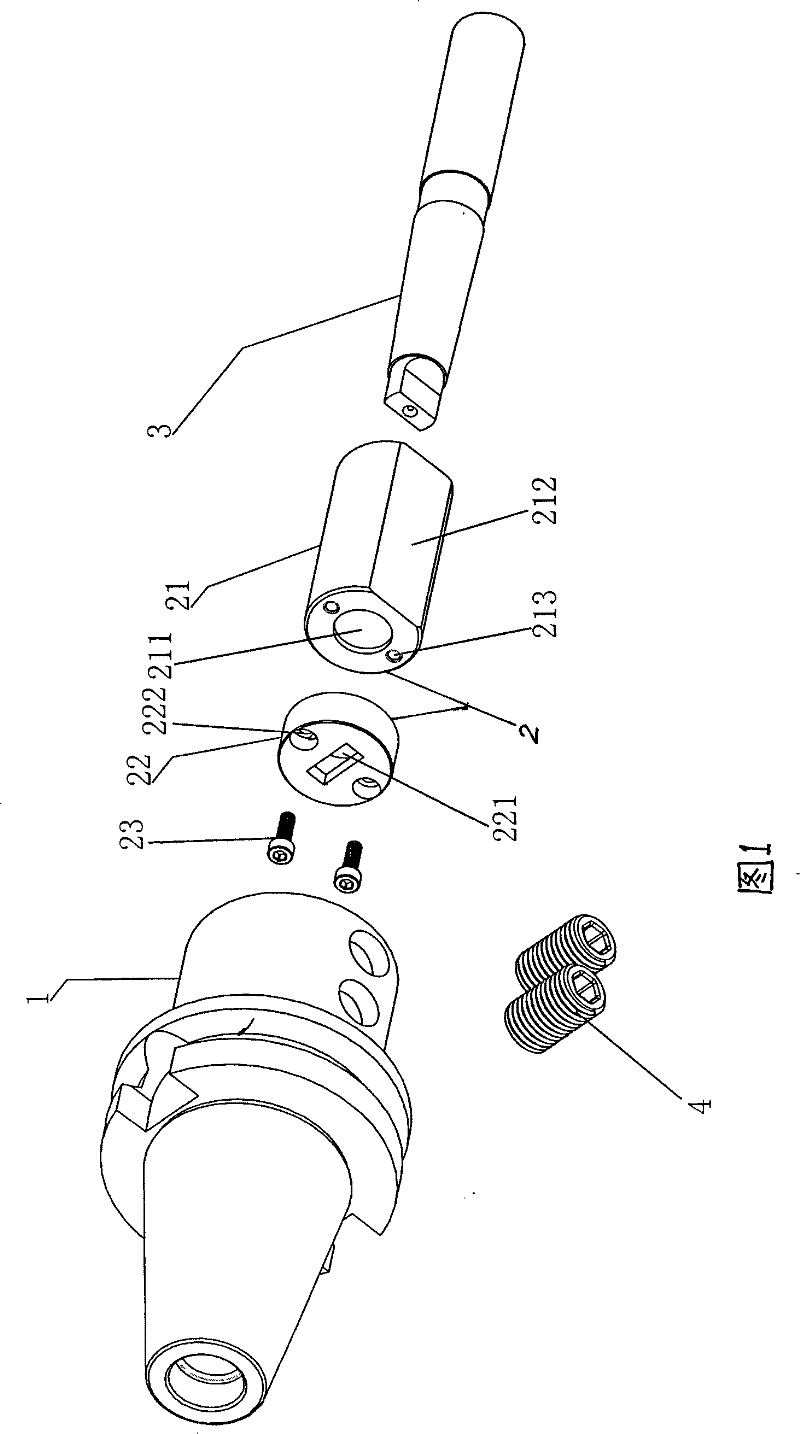

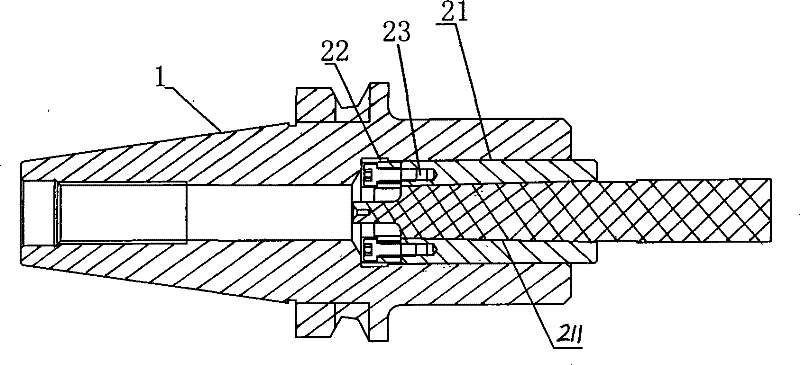

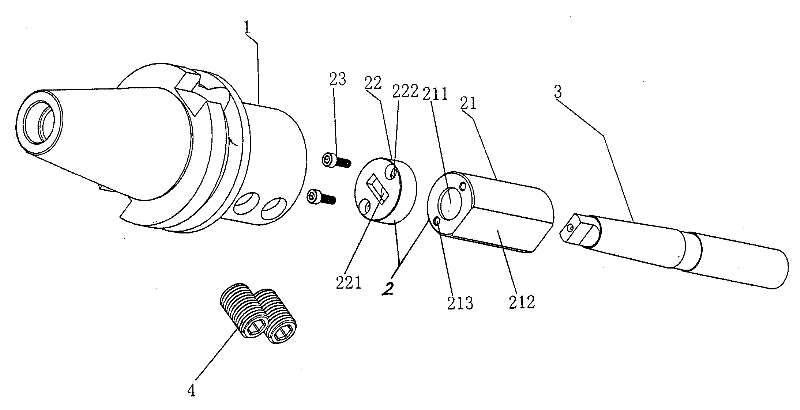

[0019] refer to figure 1 with figure 2 , this embodiment includes a connecting handle 1, a self-locking mechanism 2, a conical tool handle 3 and a screw fastener 4; the self-locking mechanism 2 is composed of a sleeve body 21, an anti-rotation seat 22 and a connecting piece 23, and the center of the sleeve body 21 is set There are axial conical through-holes 211 and at least two connecting through-holes 213, and the outer wall of the casing 21 is provided with an anti-rotation plane 212; the anti-rotation seat 22 is provided with an axial positioning through-hole 221 and at least two through-holes 222 The connecting piece 23 is matched with the connecting hole 213, and the sleeve body 21 and the anti-rotation seat 22 are connected into an easy-to-assemble and disassemble fixed connection structure by connecting the through hole 213 and the through hole 222; the axial conical through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com