Synthesis method for preparing perovskite series ceramic nano-powder body with texture lamellar structure

A nano-powder and synthesis method technology, which is applied in the field of ultra-fine powder preparation, can solve the problems of complex process, unfavorable process control and batch production, and achieve the effects of simplifying the process, realizing mass production, and narrowing the size distribution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a method for preparing perovskite-based ceramic nano powders with a textured layered structure, which has simple process, low cost, convenient operation and easy control of the preparation process. The method is to disperse the intermediate raw material and hydroxide synthesized by the solid phase reaction method into an organic solvent as a slurry bottom liquid under normal pressure, add metal alkoxide, and then dry the obtained slurry liquid , In the above process steps, adjustments and deletions can be made according to different types of perovskites or different intermediates, and ceramic powders with a layered structure but with ordinary perovskite compositions can be directly prepared.

[0023] The synthesized ceramic powder is formed by in-situ growth on the layered intermediate raw material powder, so it has a layered structure and a perovskite composition.

[0024] The synthesized powder with a layered structure can directly prepare a per...

Embodiment 1

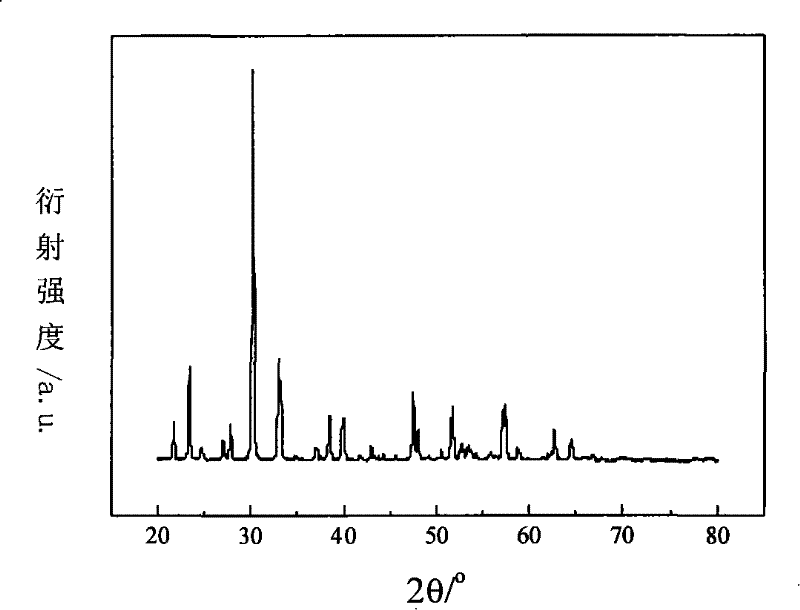

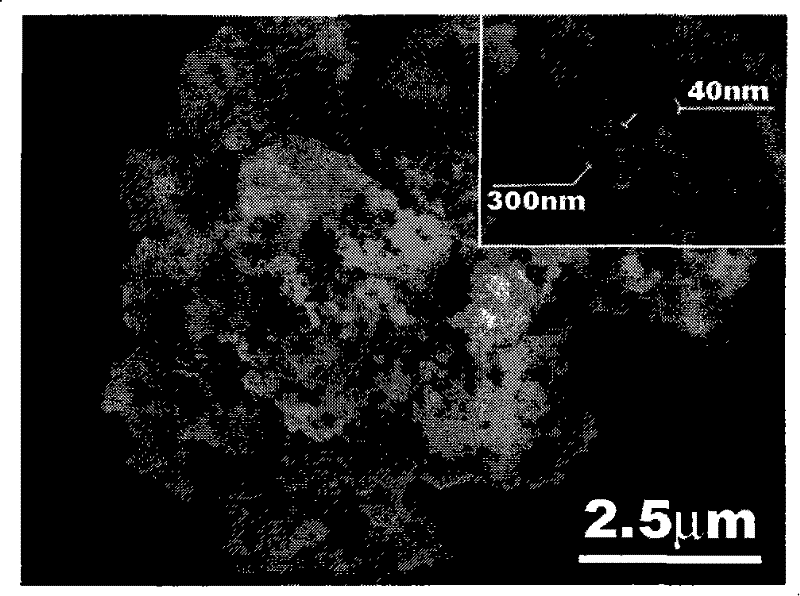

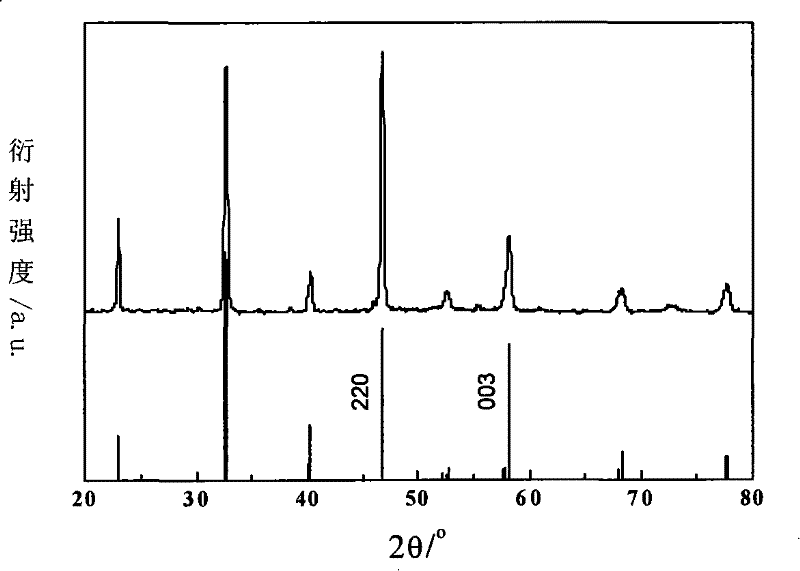

[0027] 23.97 g TiO 2 and 93.12 g Bi 2 o 3 Mixing, ball milling, and pre-calcination at 780°C, the reaction produces the intermediate raw material Bi 4 Ti 3 o 12 Powder, 5.8 g Bi 4 Ti 3 o 12The powder is dispersed into absolute ethanol as the base liquid A. Add 0.8 g of NaOH into liquid A, grind it to fully dissolve to obtain liquid B. Dissolve 8.5 g of tetrabutyl titanate into 50 ml of absolute ethanol as liquid C. Slowly add liquid C to liquid B. During the whole process, the mixing reaction temperature must be kept within the temperature range from room temperature to 100 ° C, and at the same time, it must be ground vigorously to make it fully react, so as to facilitate the control of powder properties. After the reaction was finished, filter with suction. Dry the solid part at 60-70°C to obtain Na 0.5 Bi 0.5 TiO 3 Powder. The XRD results show that the obtained powder is a fine powder with a layered perovskite structure. From the SEM photos, the finished prod...

Embodiment 2

[0029] The hydroxide in embodiment 1 is changed to 1.12 gram KOH, other conditions are constant, obtained the K with layered perovskite structure 0.5 Bi 0.5 TiO 3 Powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com