Process for forming a ferroelectric film, ferroelectric film, ferroelectric device, and liquid discharge apparatus

A ferroelectric, film-forming technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, material selection for piezoelectric devices or electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices and other directions, it can solve the problems of poor ferroelectricity, impractical technology, Pb, etc., and achieve the effect of improving ferroelectricity, suppressing the decrease of ferroelectricity, and good ferroelectricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

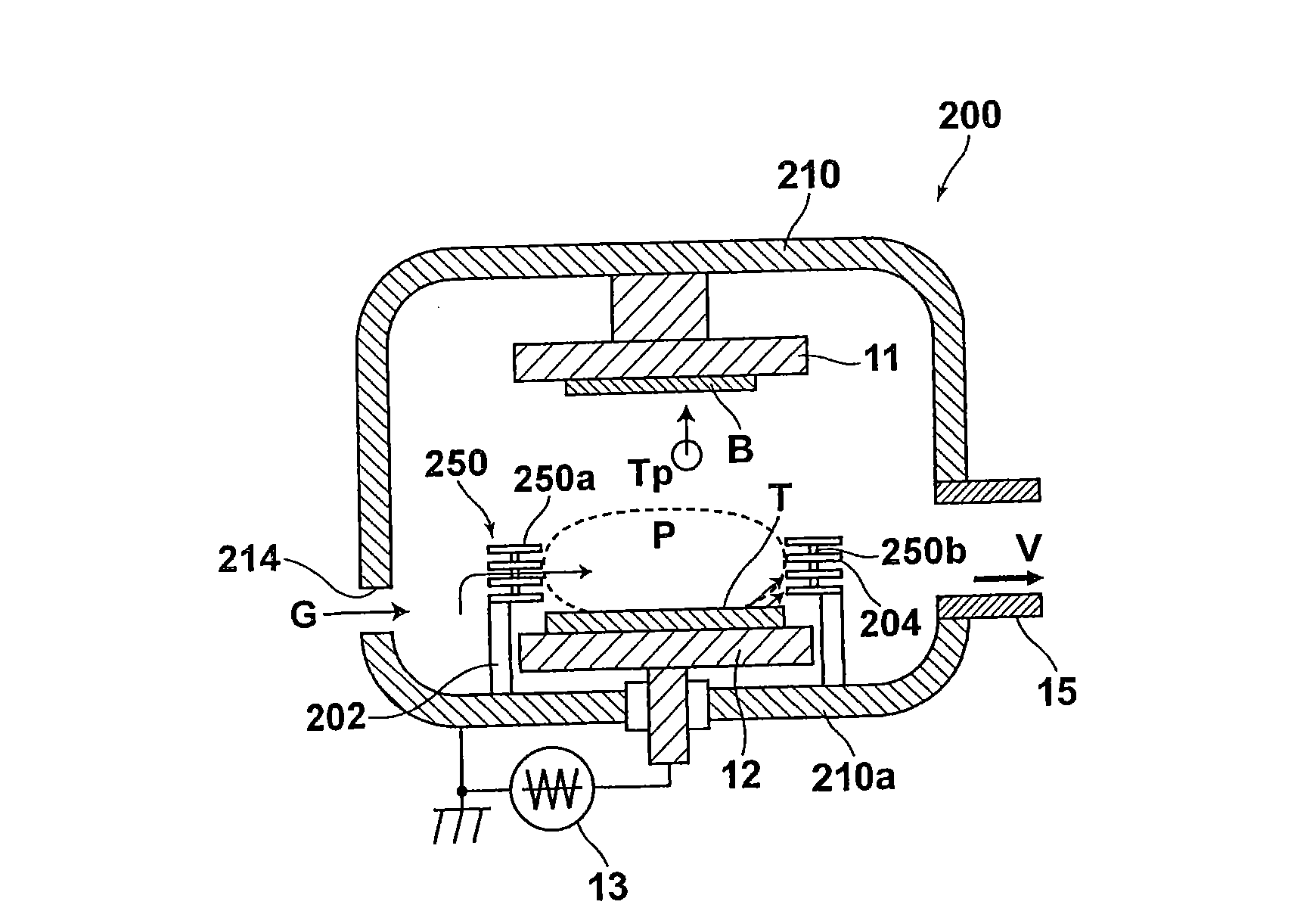

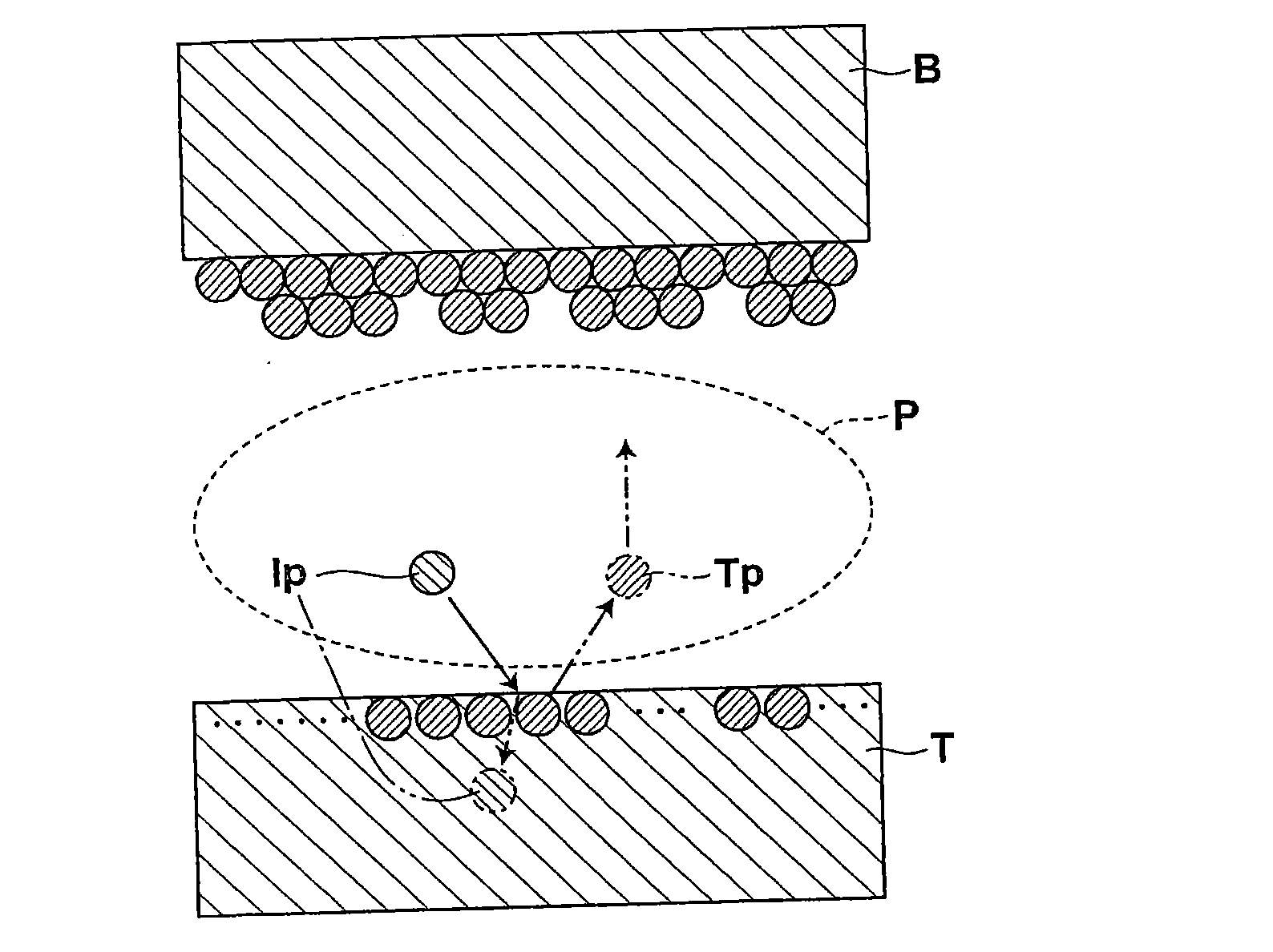

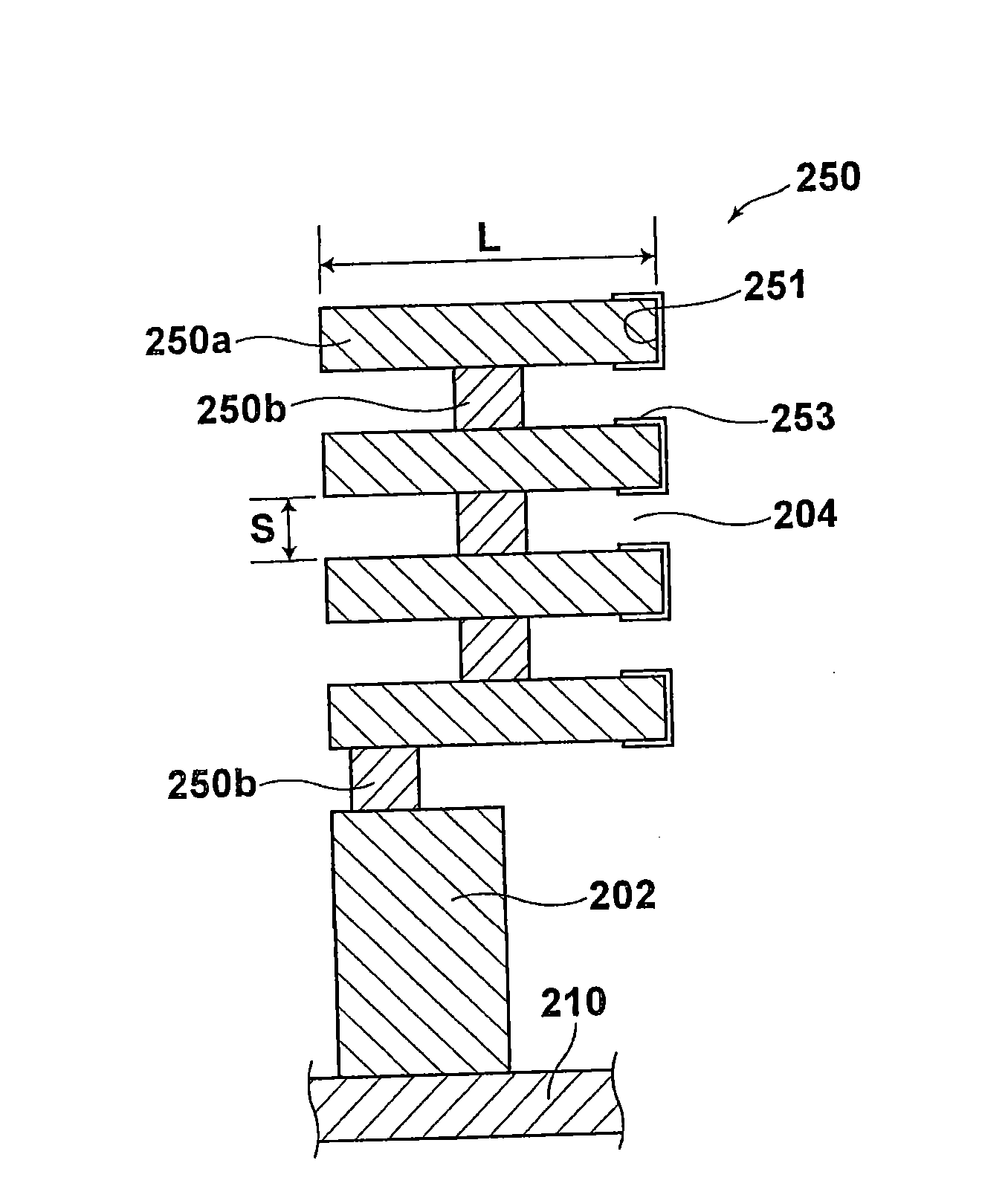

[0169] Prepare a commercially available sputtering device. Five sheets of rings 250 a , 250 a , . . . made of stainless steel (SUS) were set to ground potential and placed along the side of the target T with a diameter of 120 mm in the sputtering apparatus. Each of the rings 250a, 250a, . . . has an inner diameter of 130 mm, an outer diameter of 180 mm, and a thickness of 1 mm. In this way, obtained as Figure 1A The film formation device described in . The rings 250a, 250a, . . . are stacked on top of each other such that columnar conductive spacers 250b, 250b, . Each of the spacers 250b, 250b, ... is substantially smaller in size than each of the rings 250a, 250a, .... Accordingly, the gas G introduced into the vacuum chamber 210 can pass through the space 204 between the adjacent ones 250a, 250a without being adversely affected by the spacers 250b, 250b, . . . , and thus can reach the target T easily.

[0170] The separation distance between the substrate B and the targ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com