Packer packing multi-layer hydropower abrasive perforating and fracturing integrated technique

A process method and technology of hydraulic ejector are applied in the fields of multi-layer perforation and fracturing of oil and gas wells, which can solve the problems of large physical property difference, leakage, and insufficient fracturing of the upper layer, so as to achieve convenient and simple construction, short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

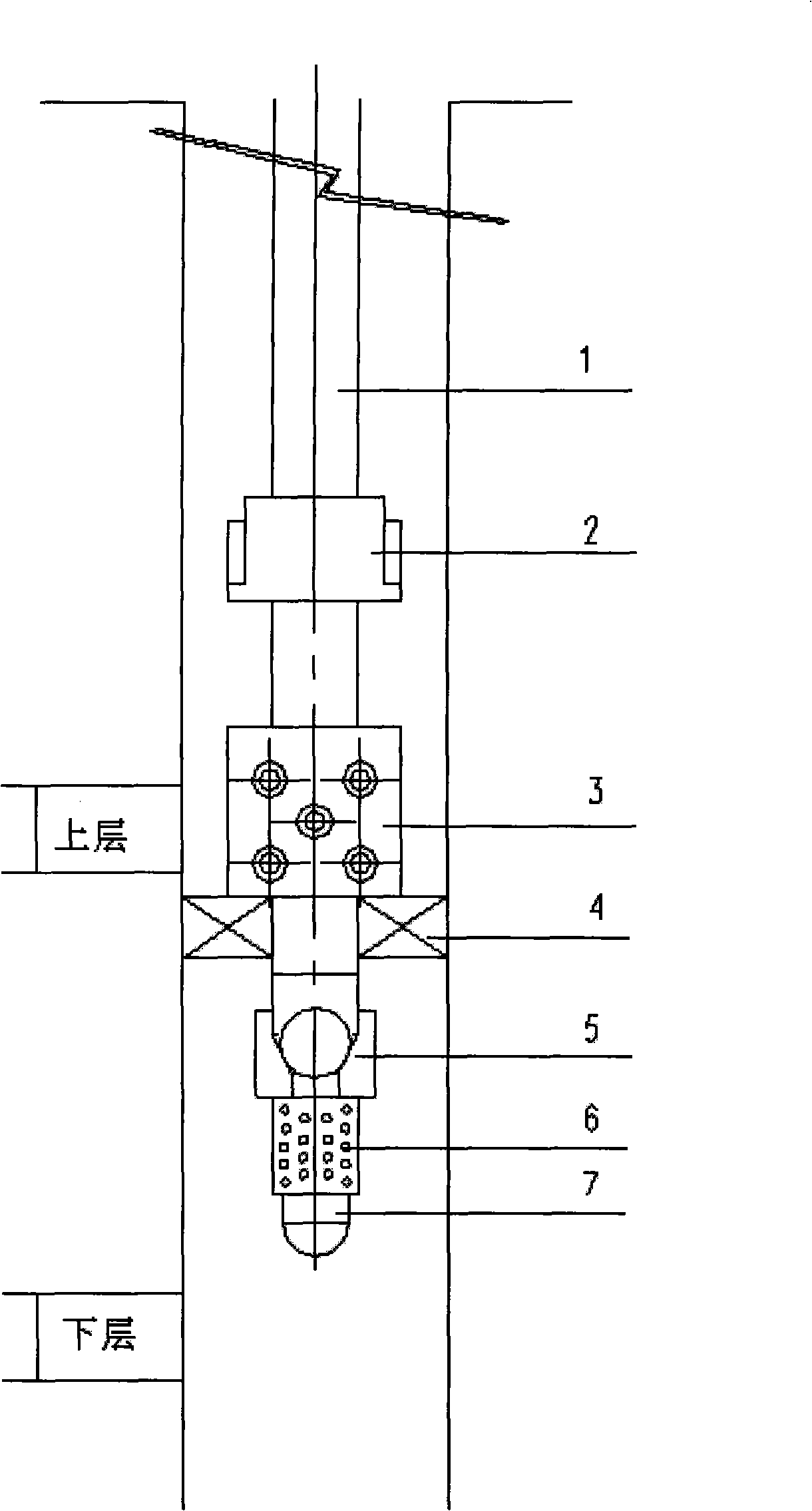

[0021] Embodiment 1: Taking an oil well with upper and lower oil layers as an example, the integrated process of hydraulic sand blasting perforation and fracturing with a packer for sealing multiple layers is described in detail.

[0022] For example, in a directional oil well, there are two different types of sandstone reservoirs at the upper and lower layers, the interval between layers is 20m, the fracture pressure of the upper formation is 38MPa, and the reservoir is dense and the fracture pressure is high; the fracture pressure of the lower formation is 30MPa, and the reservoir fracture pressure is relatively low.

[0023] refer to figure 1 . The process string is composed from top to bottom: oil pipe 1, safety joint 2, hydraulic injector 3, K344 packer 4, check valve 5, screen pipe 6, and plug 7. The nozzle aperture of the water jet 3 is 6 millimeters, and the number of nozzles is 6. The arrangement relationship of the nozzles is a symmetrical arrangement, and the uppe...

Embodiment 2

[0031] Embodiment 2: It is basically the same as Embodiment 1, except that the packer used is the Y344 packer. Another difference is the nozzle, the nozzle aperture is 5 mm; the number of nozzles is 16; the arrangement of the nozzles is symmetrically distributed, and the 16 nozzles are divided into 4 rows, and each row is distributed in a spiral form from bottom to top.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com