Universal fluctuation aerosol sprayer carburetor

A machine carburetor and smoke technology, applied in the field of smoke machine components, can solve the problems of carburetors not working, prone to failure, unusable, etc., and achieve the effects of light weight, convenient operation, and prevention of airflow backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

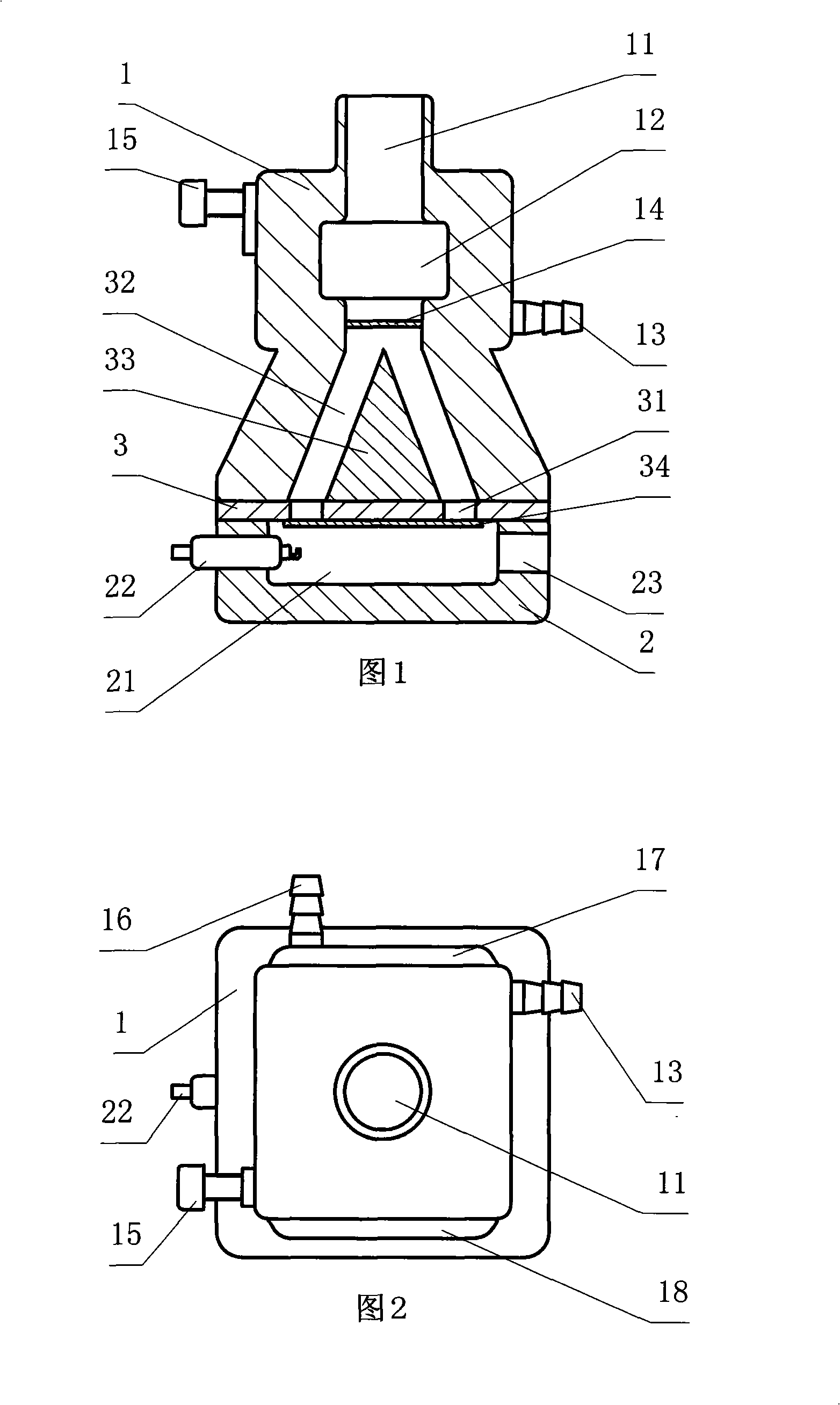

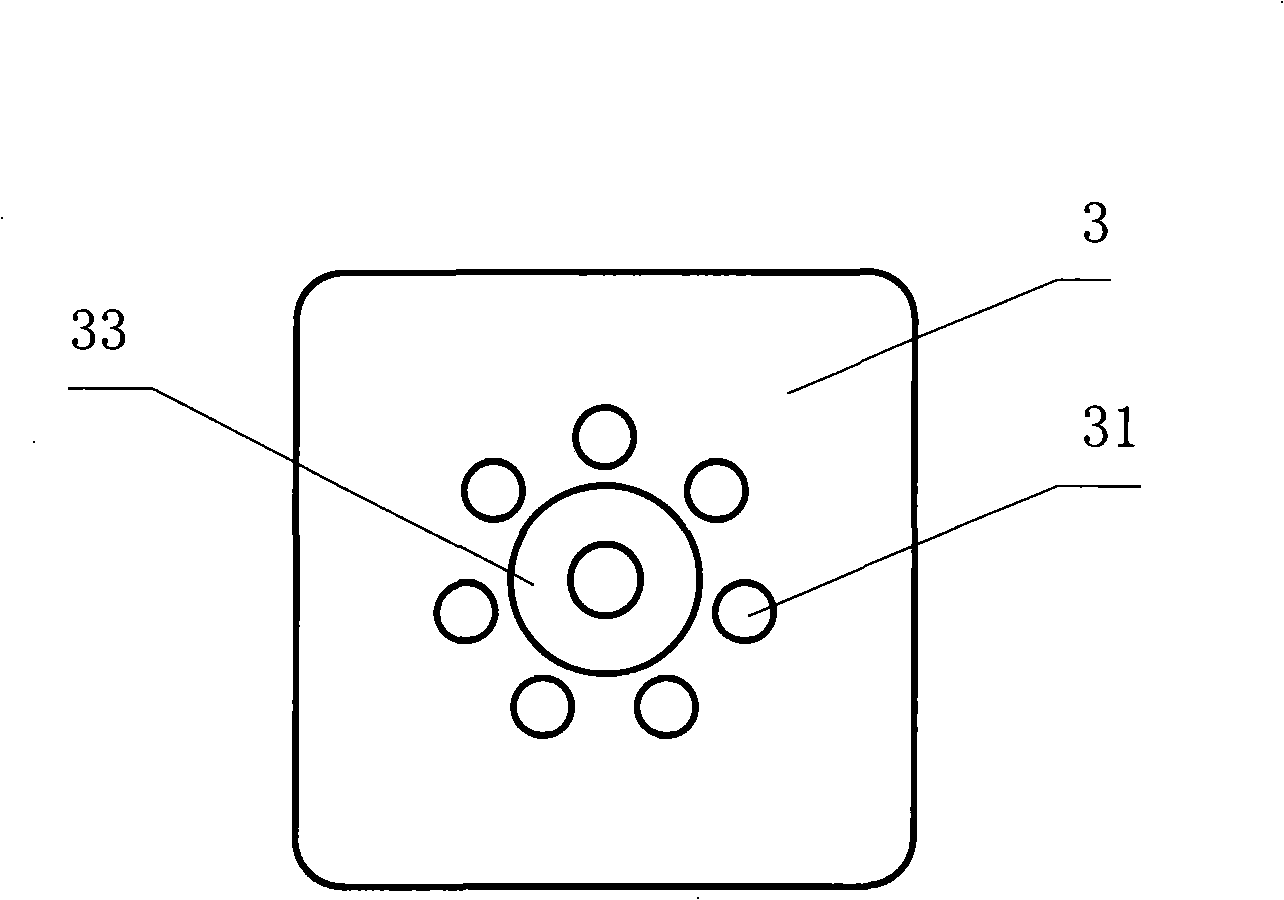

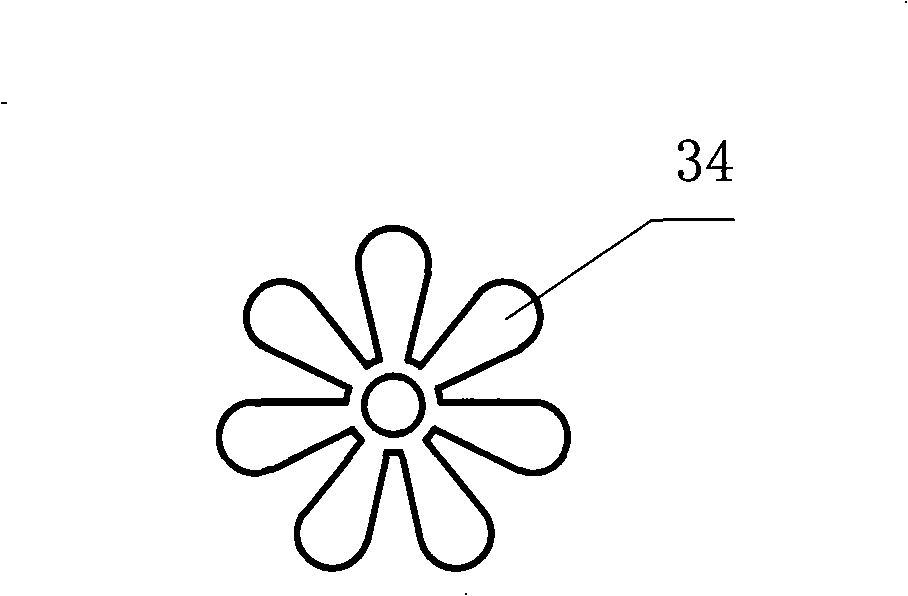

[0021] As shown in Figures 1-4, a universal pulsating smoke machine carburetor includes an upper casing 1 and a lower casing 2, and an air inlet 11 is arranged on the top of the upper casing 1, and the air inlet 11 It communicates with the oil-gas atomization chamber 12 in the upper casing 1, and an oil inlet pipe 13 is arranged on one side of the upper casing 1, and the oil inlet pipe 13 communicates with the oil-gas atomization chamber 12, and a A diversion valve 14, a combustion chamber partition 3 is placed under the upper casing 1, and a diversion hole 31 is arranged on the combustion chamber partition 3, and the combustion chamber partition 3 and the lower part of the upper casing 1 form a diversion cavity 32. A combustion chamber 21 is formed between the combustion chamber partition 3 and the lower casing 2. An igniter 22 is installed on one side of the combusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com