Stress-relief blasting method

A technology of stress relief and blast holes, which is applied in blasting and other directions to ensure safety and progress of excavation, improve safety and eliminate hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

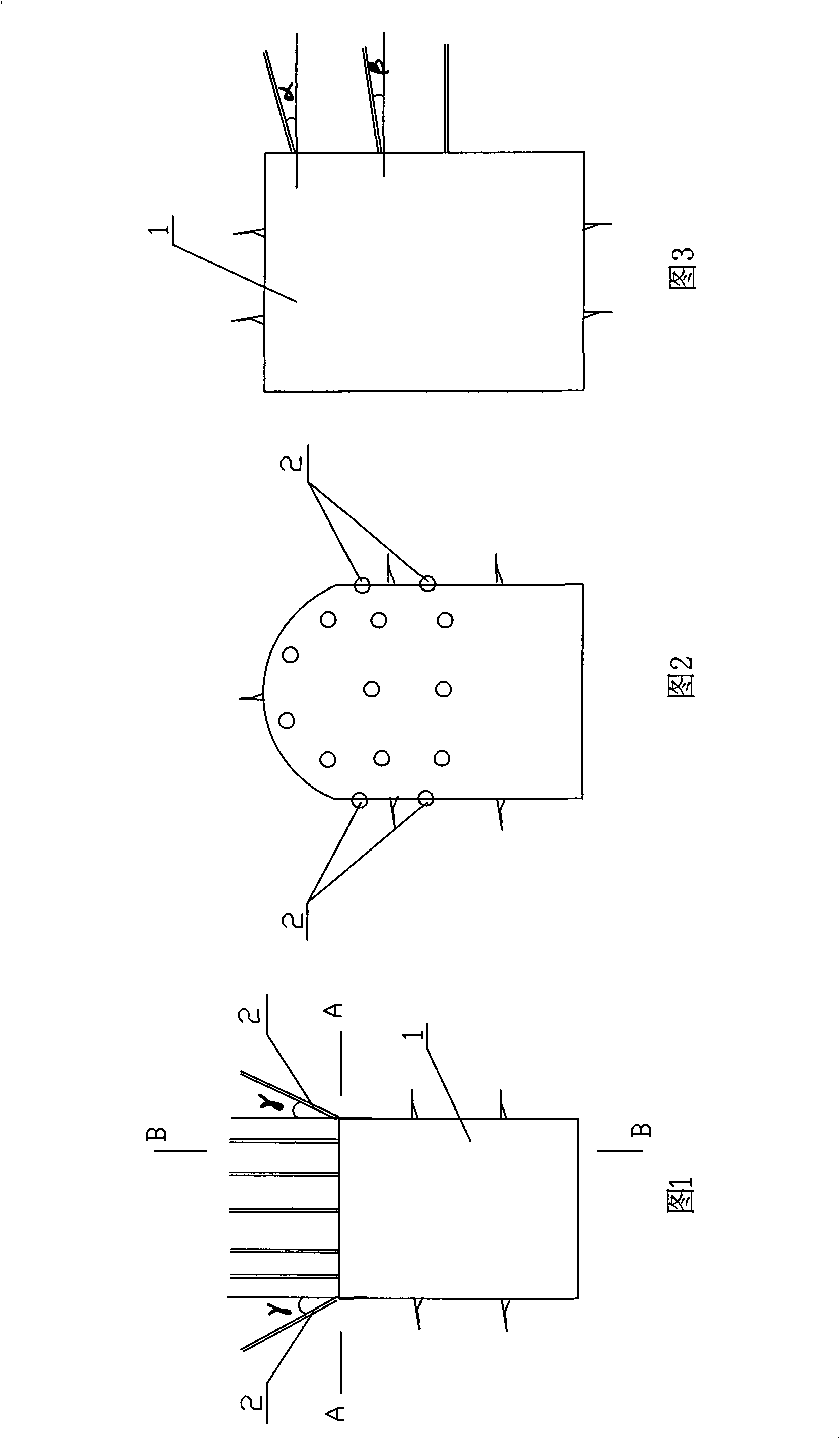

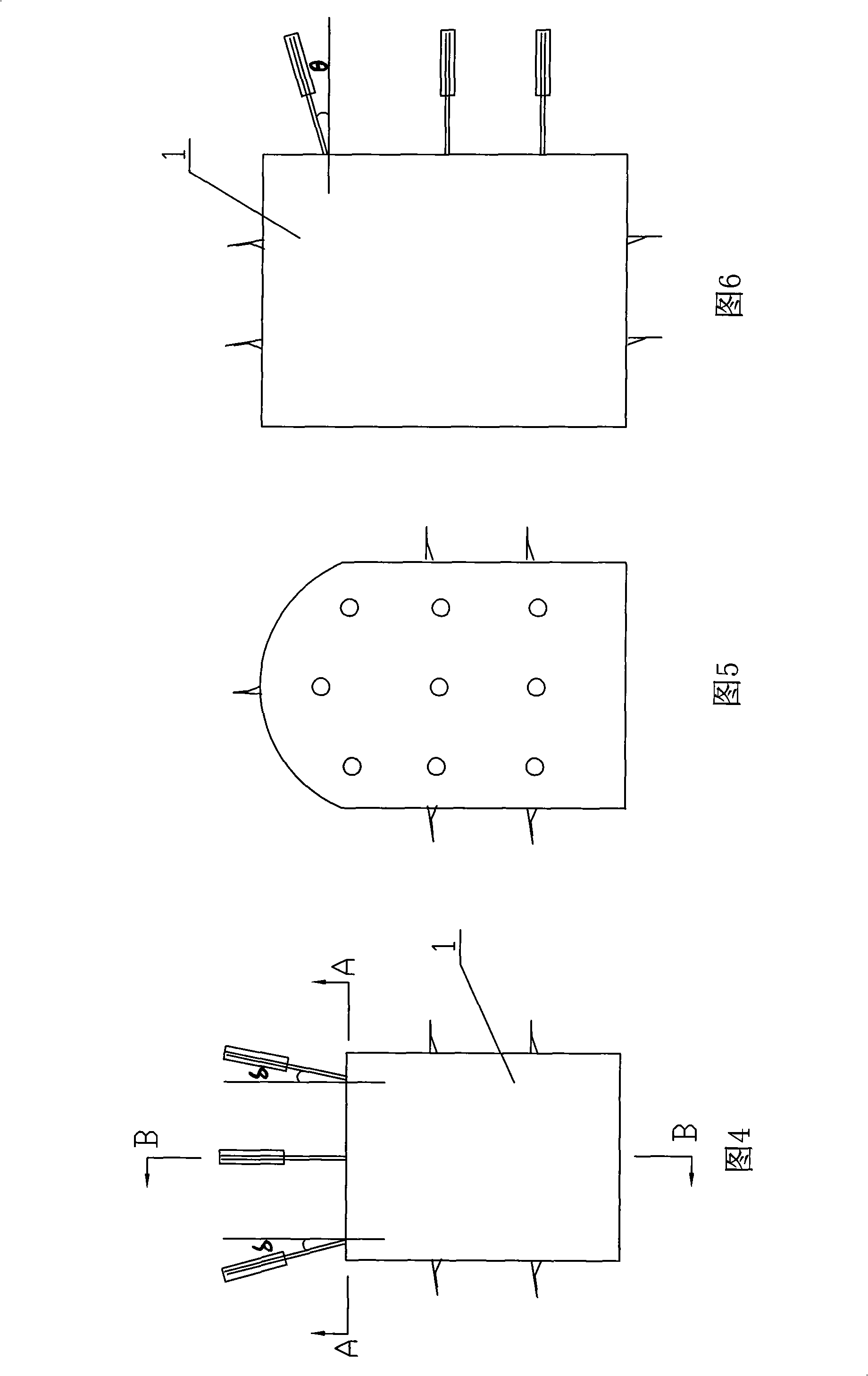

[0019] The steps of this embodiment include:

[0020] a. Drill a blast hole on the face of the tunnel, and its aperture is consistent with the diameter of the excavated blast hole;

[0021] b. Charge explosives in the blast hole;

[0022] c. Detonate after charging is completed;

[0023] For tunnel (tunnel, roadway) engineering, the above-mentioned stress-relieving blasting method can be incorporated into the normal blasting work procedure, but the stress-relieving blasting hole is given priority to blasting, and then the normal excavation blasting is carried out. The time delay between the two When there is no special requirement, the time delay between any two adjacent initiation sequences of on-site excavation blasting can be used. The blasting holes are generally arranged in the stress concentration area, and the principle of the hole depth is to reach or pass through the stress concentration area; at the same time, the number of blasting holes, the size of the hole and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole length | aaaaa | aaaaa |

| Elevation angle | aaaaa | aaaaa |

| Elevation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com