Gas meter leak tightness detecting method and device thereof

A sealing detection and gas meter technology, which is applied in measuring devices, testing/calibrating devices, liquid tightness measurement using liquid/vacuum degree, etc. It can solve problems such as easy misjudgment, affecting the quality of gas meters, and large temperature influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

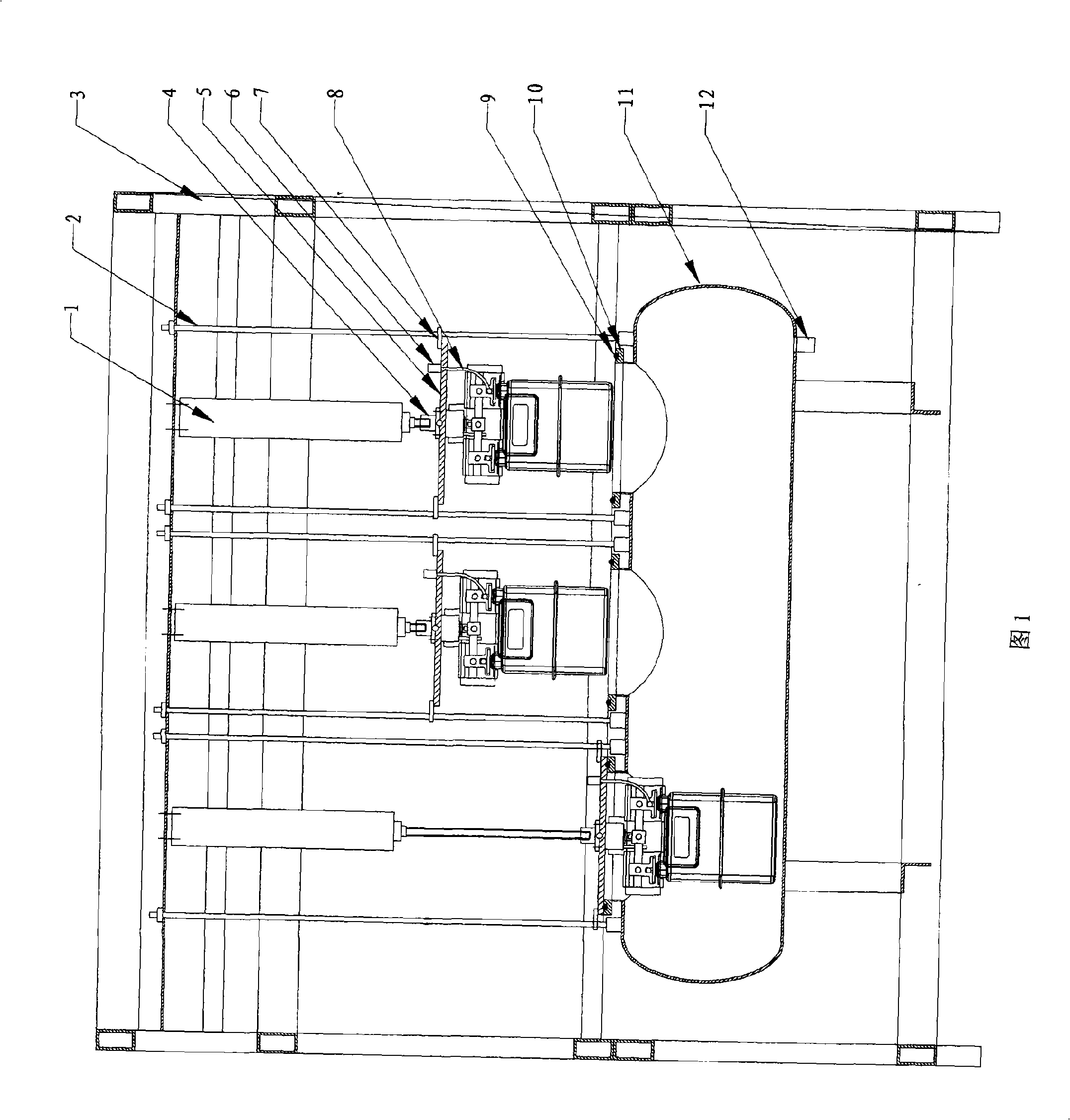

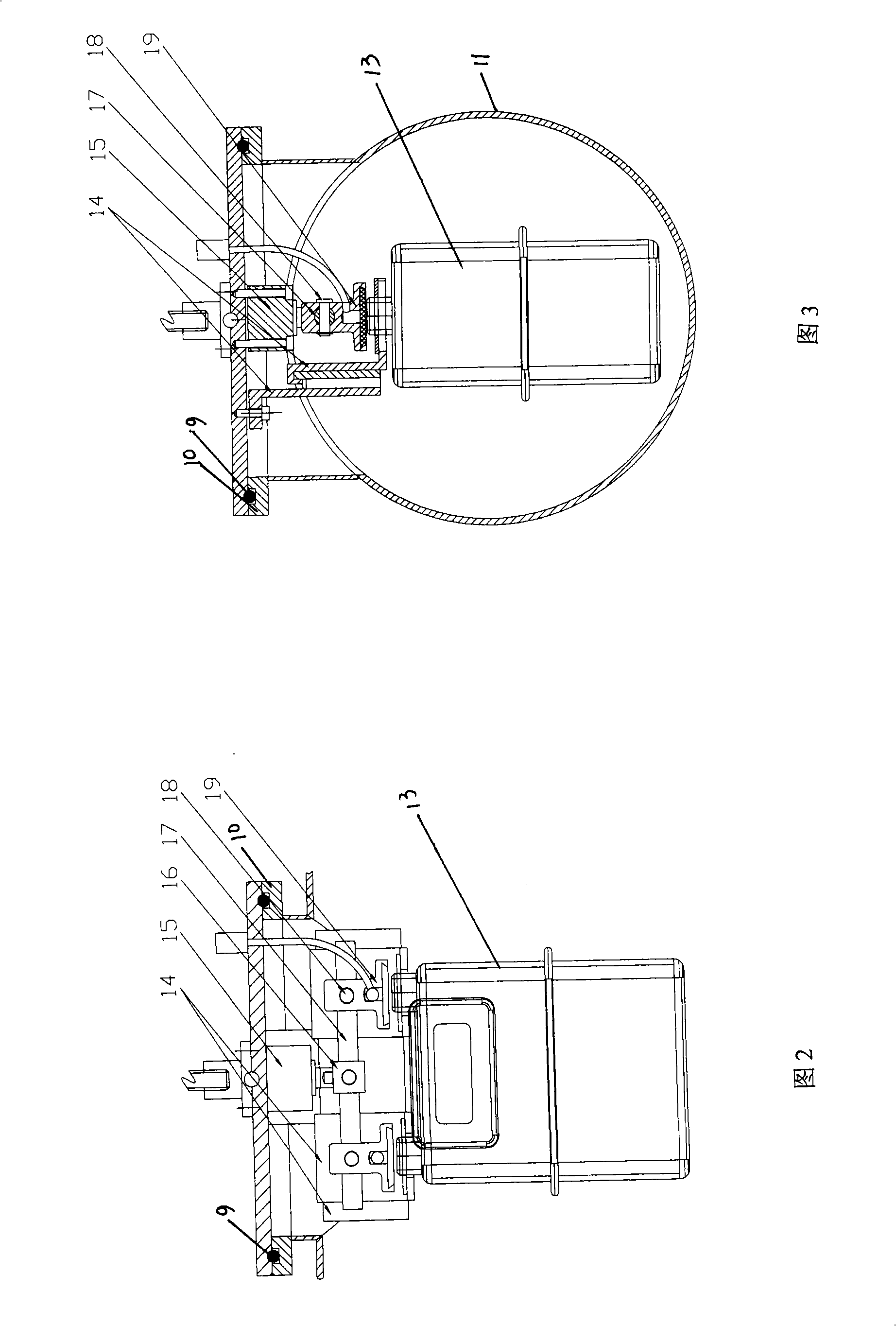

[0015] As shown in Figure 1, the airtightness detection device of the gas meter comprises a barrel-shaped airtight container 11, a cylinder 1, a pull rod 2, a cover plate 5, a hanging meter sealing mechanism, an airflow conduit 8 and an airflow detection port 6, and the upper part of the barrel-shaped airtight container 11 is There are three openings (the number of openings can be opened according to the number of meters to be checked once), each opening is welded with a flange ring 10, and the flange ring 10 is provided with an O-shaped sealing ring 9. The lower end of the airtight container 11 is provided with a suction port 12 . The cylinder 1 is arranged above each opening, the cover plate 5 is connected with the piston rod of the cylinder 1 through the connector 4, the cover plate 5 corresponds to the upper and lower positions of the opening of the sealed container 11, and the air flow detection port 6 is arranged at the upper end of the cover plate 5 . The bottom end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com