Joint shaft and roller displacement unit therefor

A mobile unit, universal joint shaft technology, applied in the direction of coupling, elastic coupling, transportation and packaging, etc., can solve problems such as passenger injury, and achieve the effect of reducing sound, reducing sound and saving weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

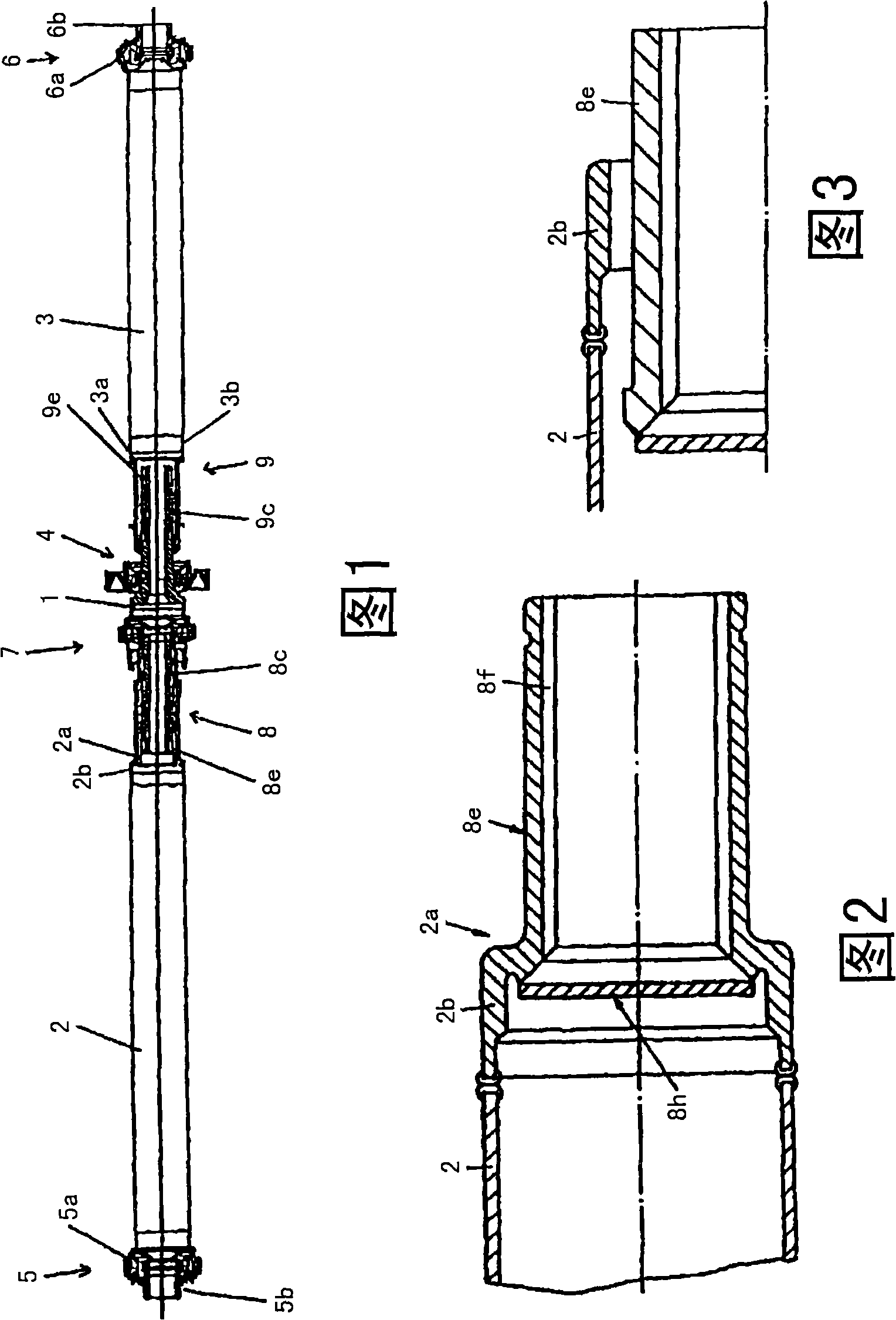

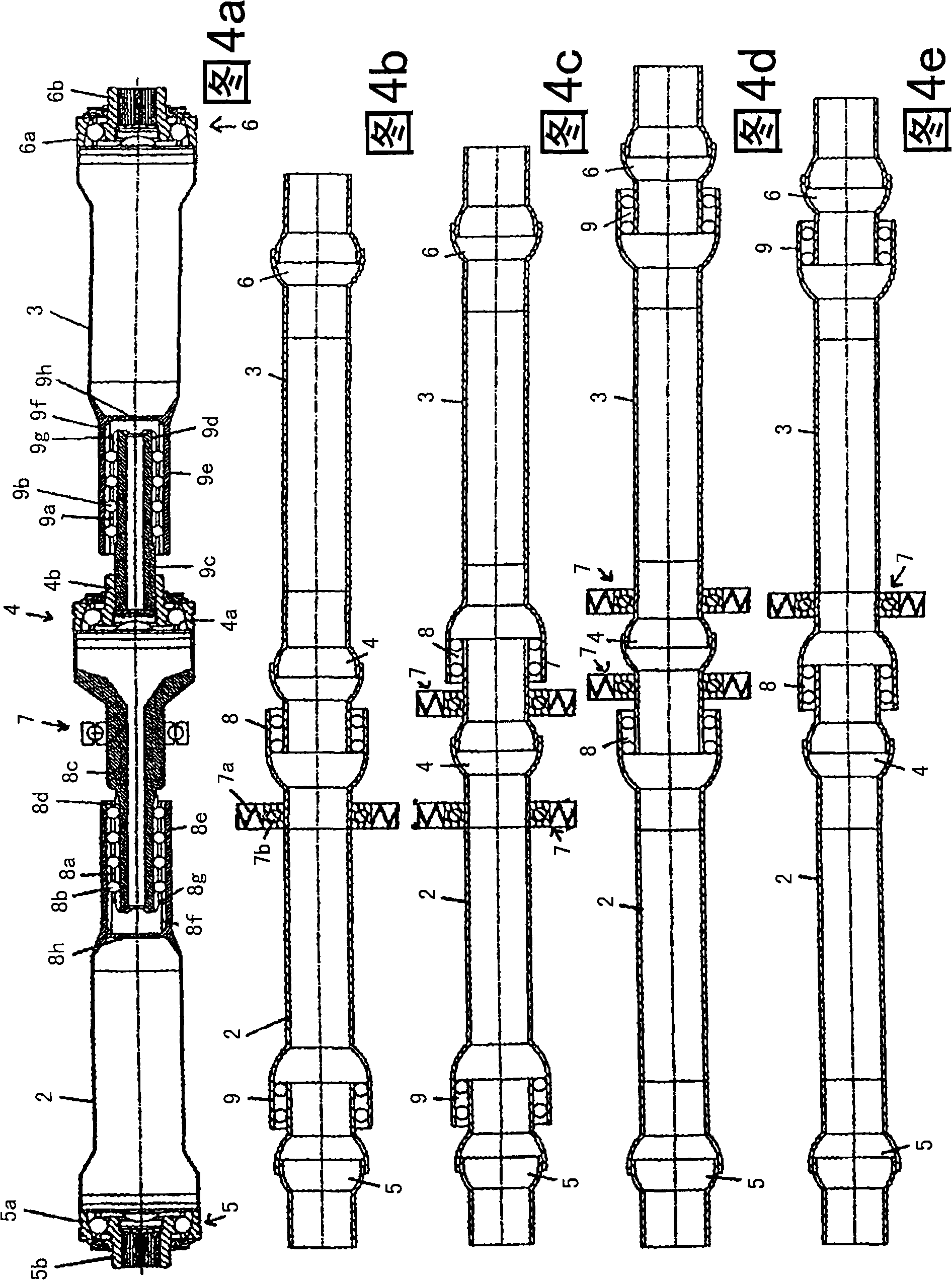

[0032] The cardan shaft 1 shown in FIG. 1 comprises a first shaft section 2 and a second shaft section 3 which are each designed as a hollow shaft tube. The two shaft sections 2 and 3 are connected to one another via an intermediate joint 4 which, in the embodiment shown, is designed as a counter-rail joint. The transmission-side end of the first shaft section 2 facing away from the central joint is connected to a transmission-side joint 5 . The differential-side end of the second shaft section 3 facing away from the center joint 4 is connected in the same manner to a differential-side joint 6 . Here too, the transmission-side universal joint 5 and the differential-side universal joint 6 are designed as counter-rail joints.

[0033] An intermediate bearing 7 with a shock absorber 7 a and a roller bearing 7 b is assigned to the intermediate joint 4 , which in the embodiment shown can be fastened to a vehicle floor assembly via a spring element. In addition, a first roller mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com