Viewing device for polysilicon furnace

An observation device, polysilicon technology, applied in the fields of silicon compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of inability to ensure the safety of operators, inability to understand the furnace body at all times, inconvenience in daily work, etc., to achieve accurate and comprehensive observation and simple structure. , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] specific implementation plan

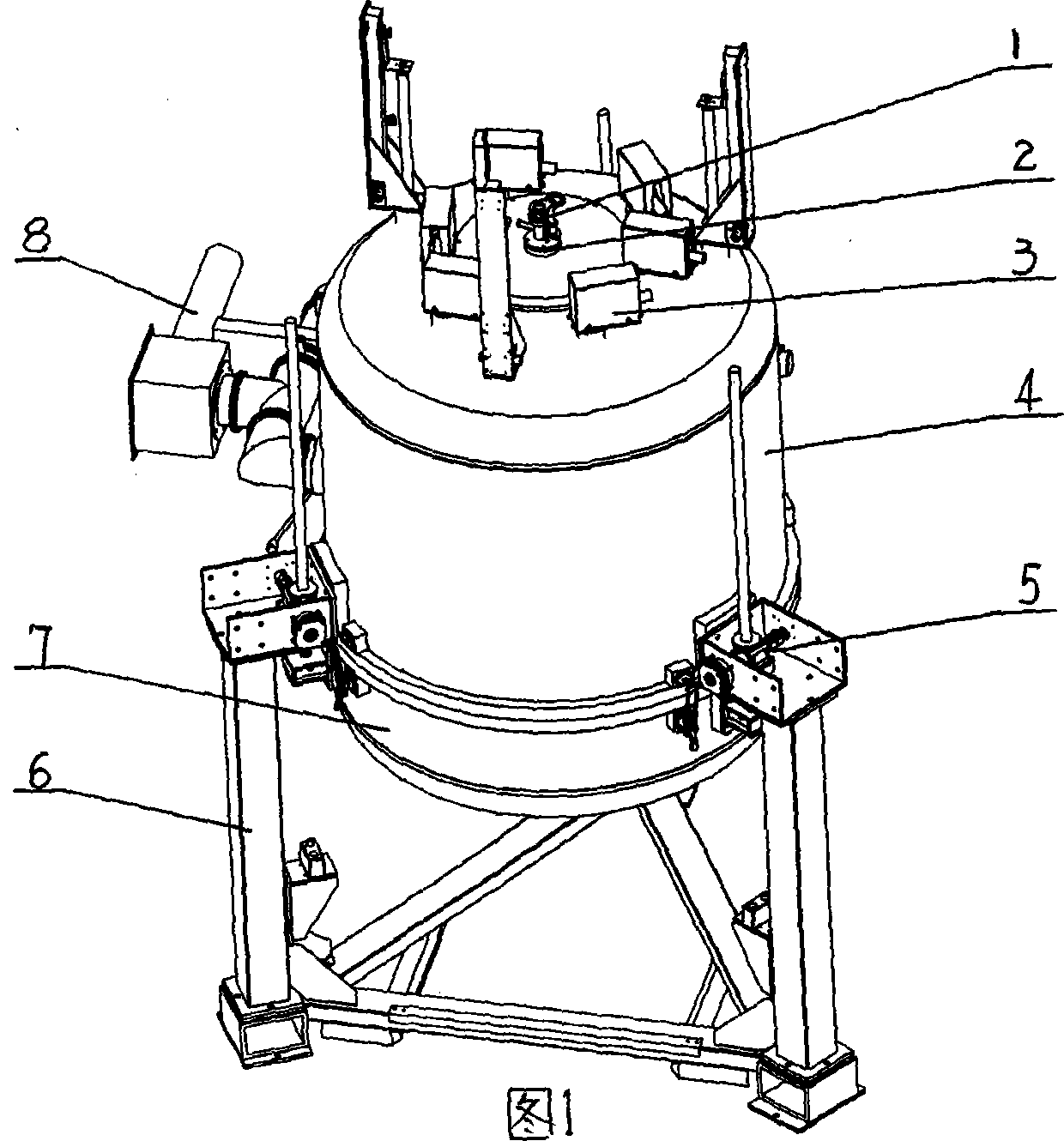

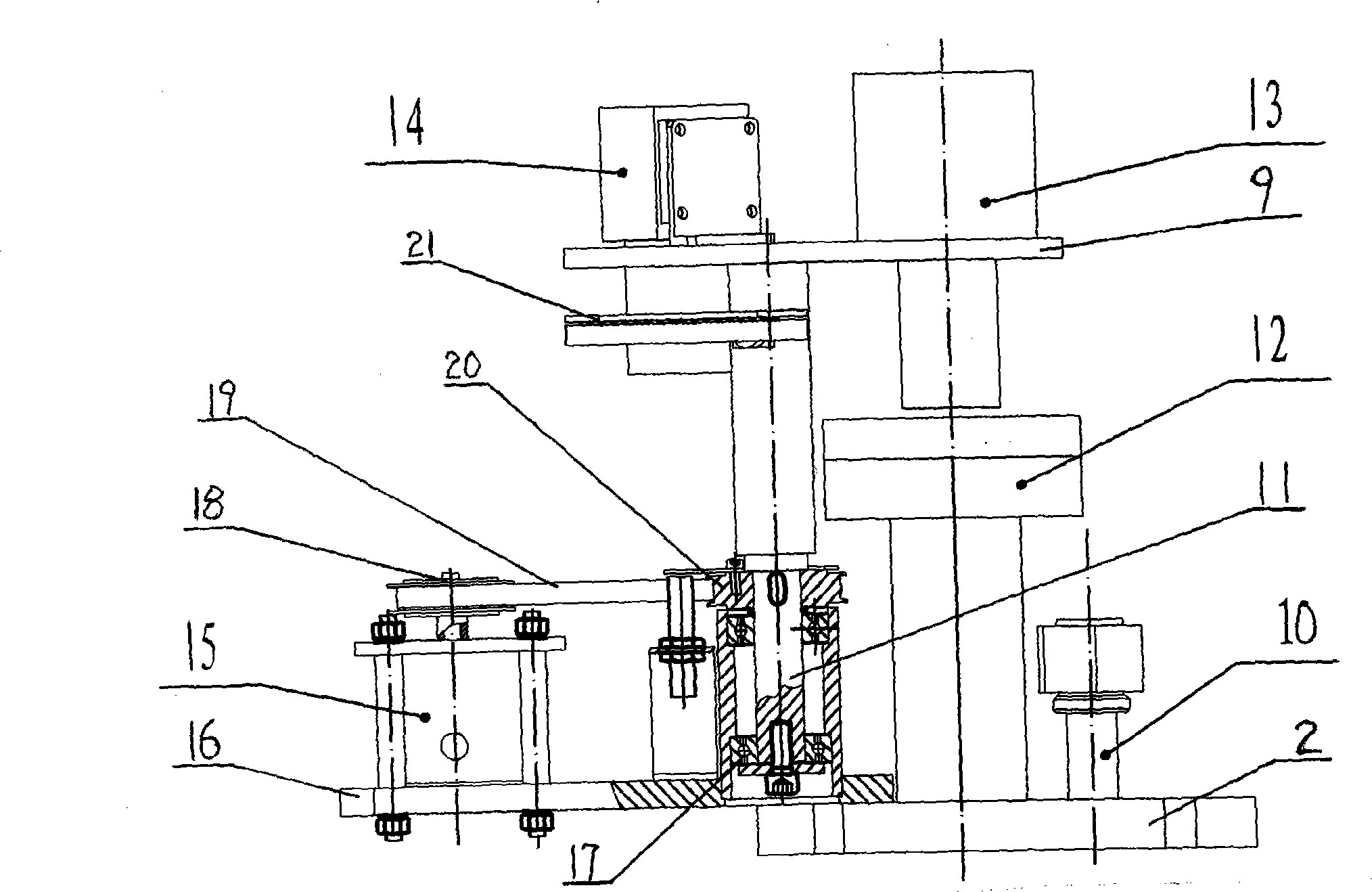

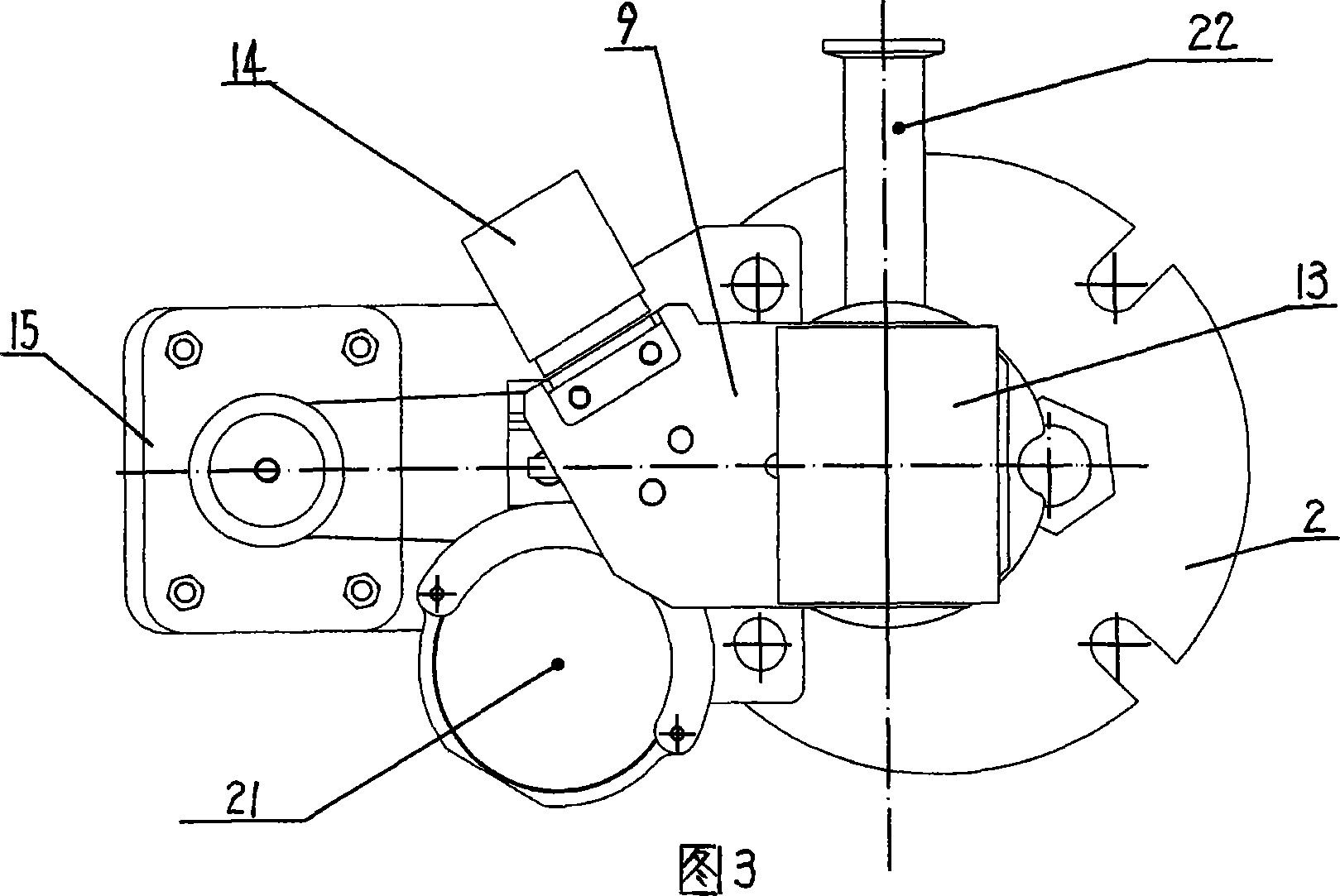

[0009] Such as figure 1 As shown, a polysilicon furnace observation device is mainly composed of a furnace body observation port base 2, an infrared thermometer probe 13, a camera 14 and an electric control motor 15. The furnace body 4 is located on the bracket 6, the upper end of the furnace body is provided with an electrical box 3, the lower end of the furnace body is provided with a furnace cover 7, the furnace body and the furnace cover are opened and closed by the furnace cover lifting device 5, and the side of the furnace body is provided with a vacuum pipe 8 is connected with a vacuum pump to keep the furnace body vacuum. The crystal growth rate measurement hole 10 and the gas inlet and outlet valve 22 are arranged on the base of the observation port of the furnace body, which are distributed in a traditional structure, so they will not be repeated here. In the present invention, an observation unit 1 is arranged on the base of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com